High precision flexible electric servo directional mechanism

An electric servo, pointing mechanism technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems that the pointing mechanism is difficult to control, reduce the service life, and have a large number of components, and achieve an increase in the rotation range, a reduction in the number of components, and a high number of components. The effect of pointing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

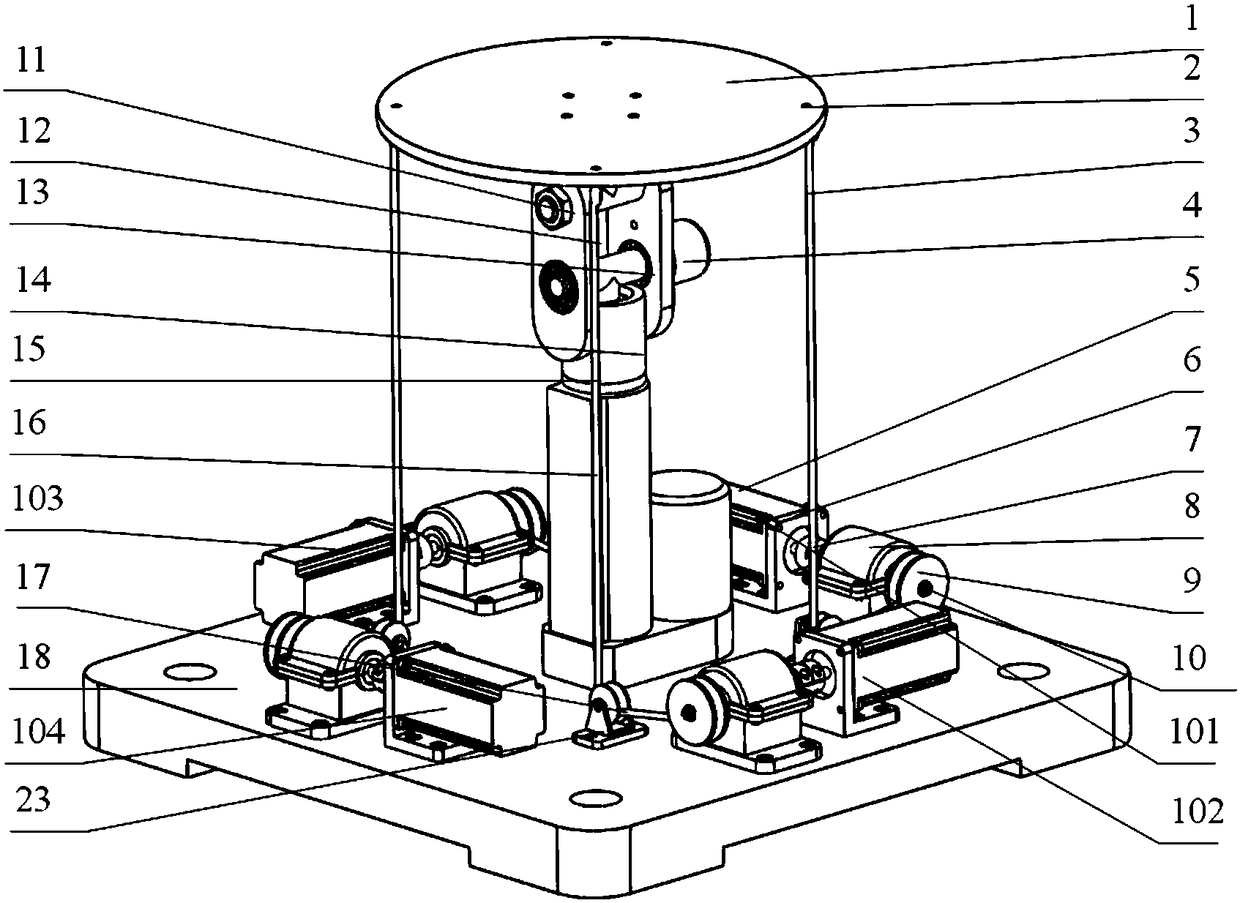

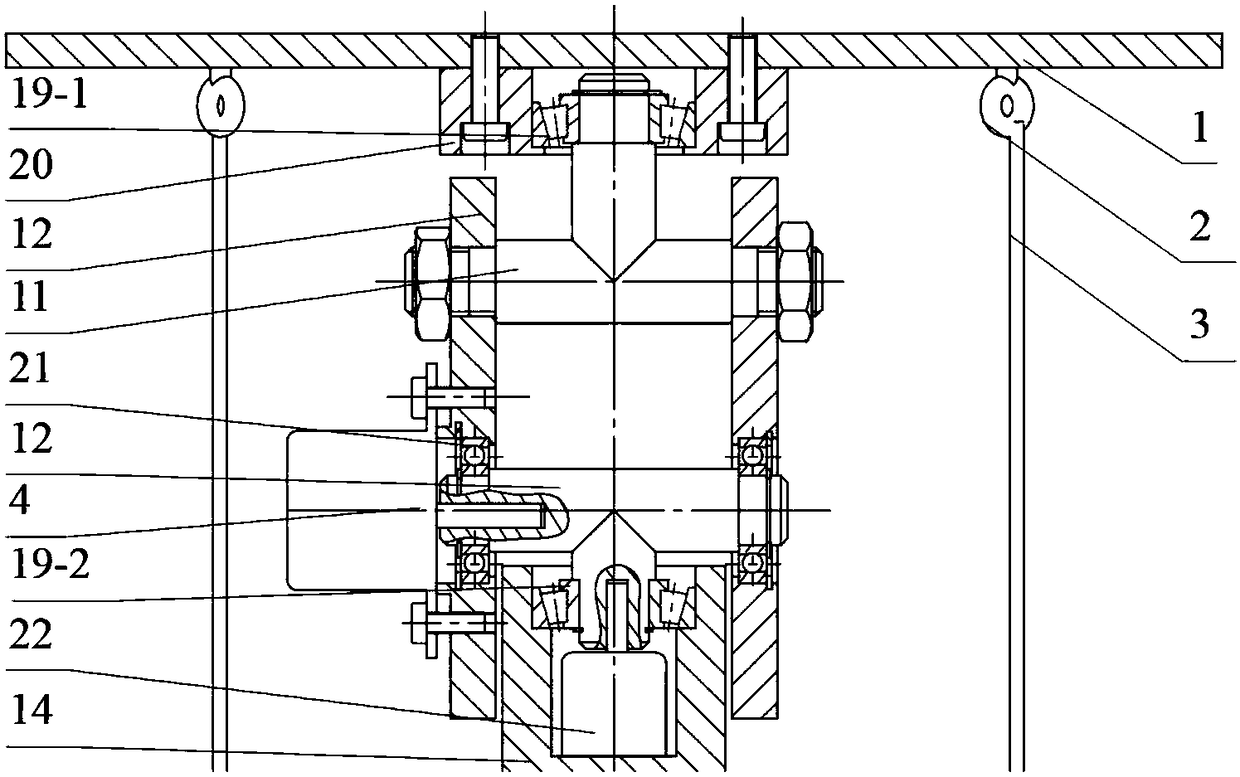

[0017] in figure 1 , figure 2 In the schematic diagram of the present invention, there are four power input systems with the same structure on the bottom plate 18. The power input system consists of a servo motor, a servo motor frame, a coupling, a reducer, a take-up reel, a pulley and a flexible rope. . The servo motor frame 6 is arranged on the platform, and the servo motor 5 is fixed on the servo motor frame. The output end of the servo motor is connected to the input shaft of the reducer 8 through the coupling 7, and the output shaft of the reducer is connected to the take-up reel 9 through the screw and the shaft end retaining ring 10, and the take-up reel and the shaft end retaining ring are both set in On the output shaft of the reducer. Four pulley brackets 23 are provided on the platform, and each pulley bracket is provided with a pulley 17. Four rope buckles 2 are provided on the lower surface of the pointing platform 1, and the position of each rope buckle corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com