A kind of encapsulation method of thermoelectric separation heat dissipation structure for high-power LED

A technology of thermoelectric separation and heat dissipation structure, used in circuits, electrical components, semiconductor devices, etc., can solve problems such as shortened life, poor heat dissipation, and increased chip temperature, and achieve the effect of reducing thermal resistance and improving packaging methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0039] see Figure 1-7 , the present invention provides a packaging method for a high-power LED with a thermoelectric separation heat dissipation structure, comprising the following steps:

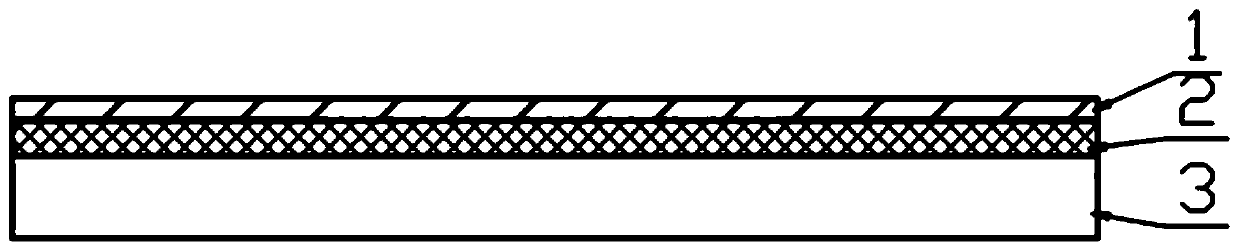

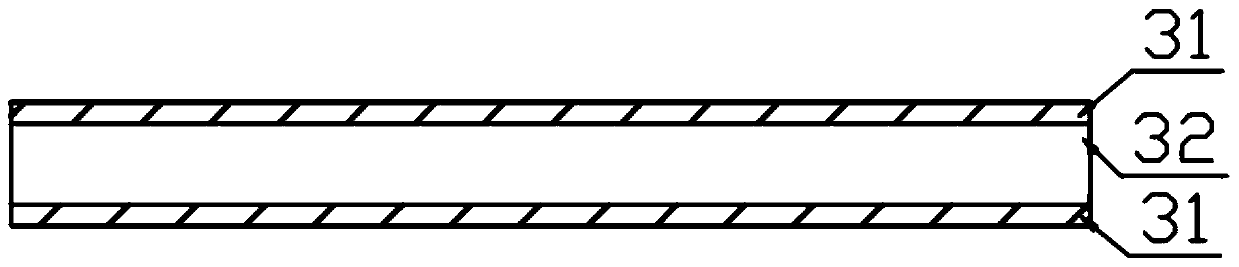

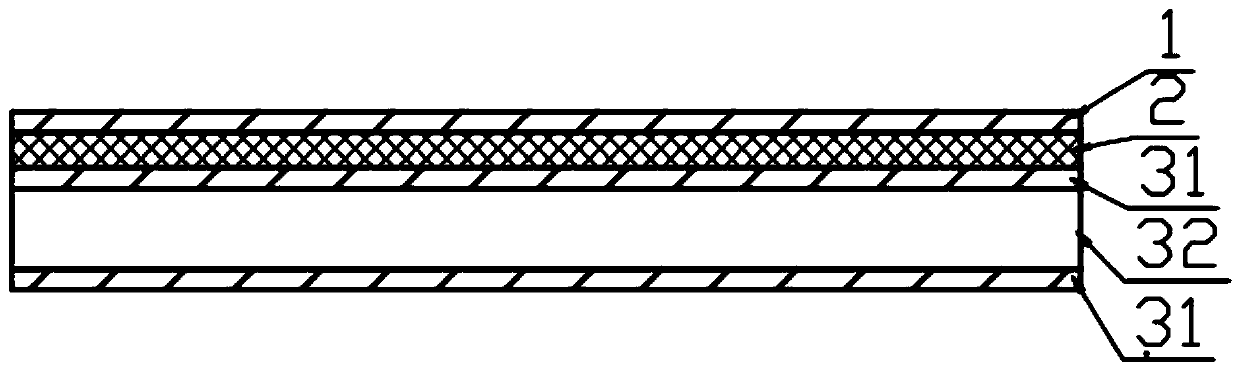

[0040] Step 1: Copper-plate the upper and lower sides of the double-sided anodized aluminum plate to form a composite heat dissipation substrate. Such as figure 2 shown.

[0041] Step 2: Cover the upper surface of the composite heat dissipation substrate with an insulating layer and a copper foil layer in turn, and then press them together. Such as image 3 shown.

[0042] Step 3: milling at one time, milling off the copper foil layer and insulating layer corresponding to the LED base on the upper surface of the copper clad laminate. Such as Figure 4 shown.

[0043] Step 4: Electroplate a copper layer with the same thickness as the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com