Patterned cover layer on base structure defining cavity and alignment marker

A technology for aligning marks and covering layers, which is applied in the fields of electric solid-state devices, semiconductor devices, multilayer circuit manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

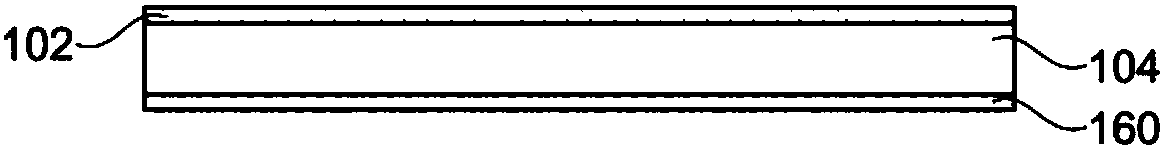

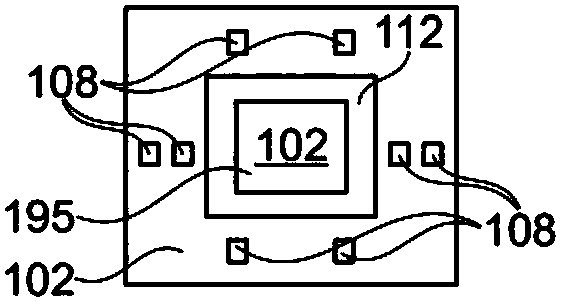

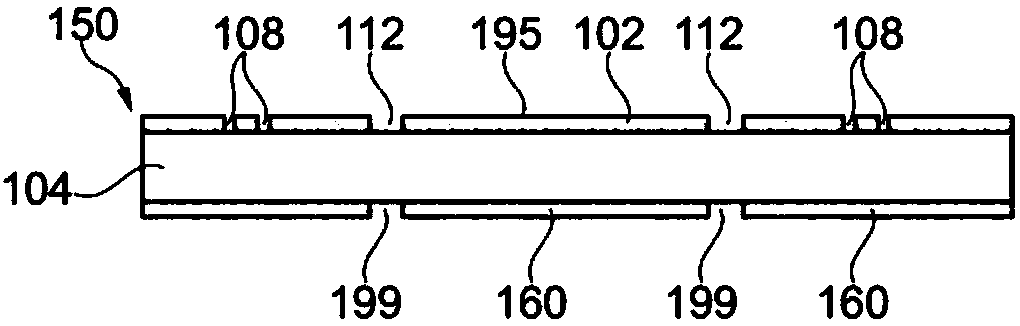

[0048] Before describing the exemplary embodiments in further detail with reference to the accompanying drawings, some basic considerations upon which the exemplary embodiments of the present invention are developed will be outlined.

[0049] According to an exemplary embodiment of the present invention, there is provided a component-embedded package with high accuracy. More specifically, an exemplary embodiment of the present invention provides a package or module with embedded electronics configured such that the entire registration chain becomes efficient and thus can be kept very small. manufacturing tolerances. By taking this measure, a high packing density can be achieved, allowing also a high degree or extensive functionality of the package in which the components are embedded.

[0050]An advantage achievable by exemplary embodiments of the present invention is high quality registration between cavities and components. Furthermore, during the laser cutting process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com