Robot auxiliary operation system and robot auxiliary operation method

A robot-assisted and operating system technology, applied in the direction of manipulators, conveyor objects, program-controlled manipulators, etc., can solve the problem that robots are difficult to perform flexible tasks, and achieve a good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

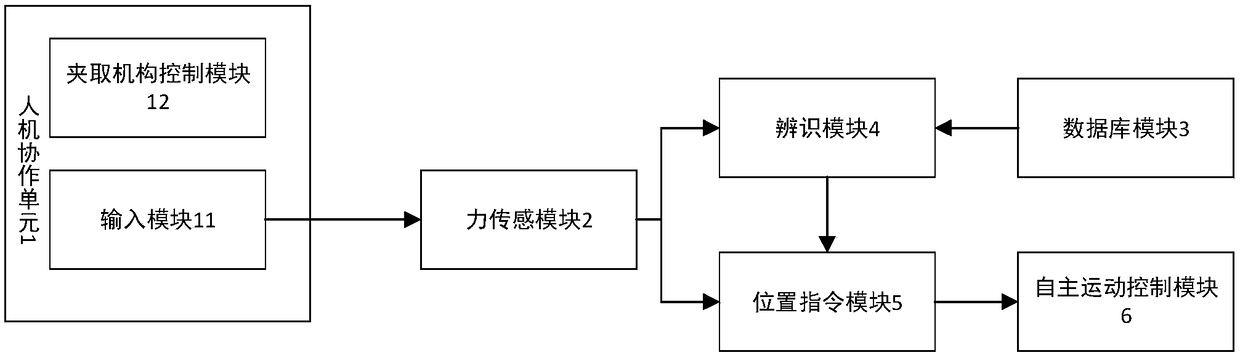

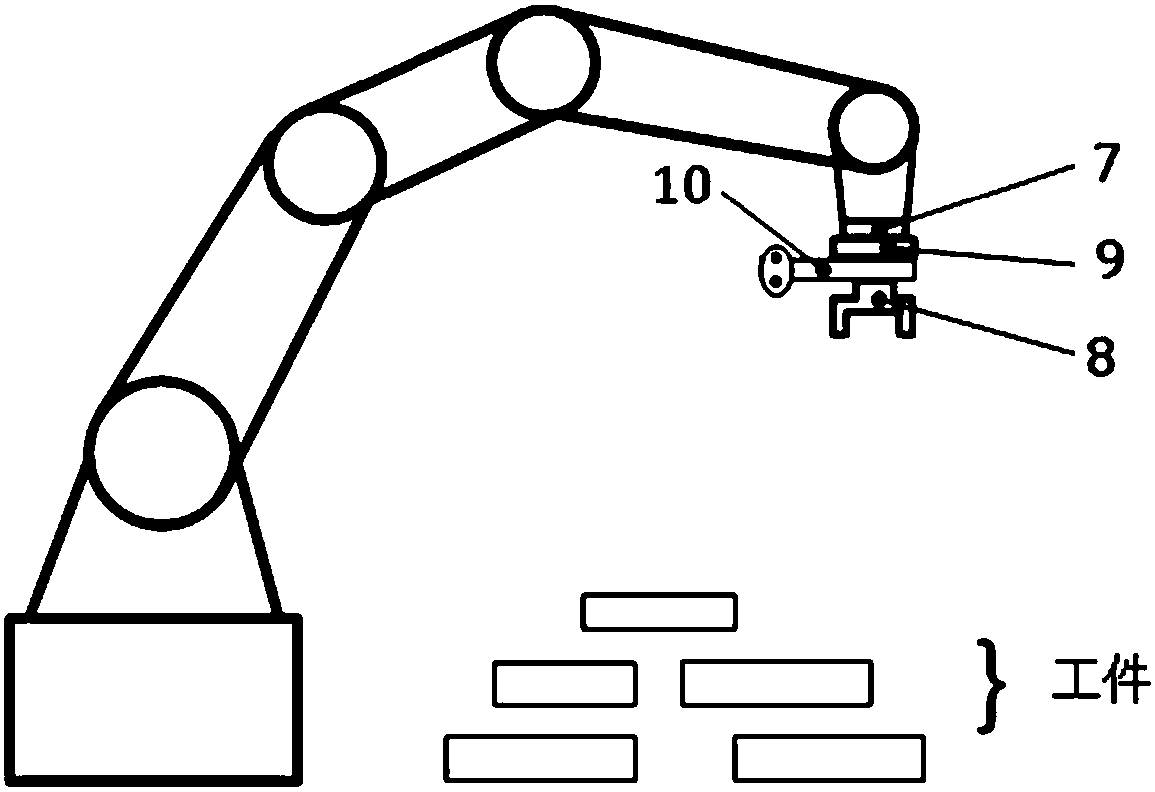

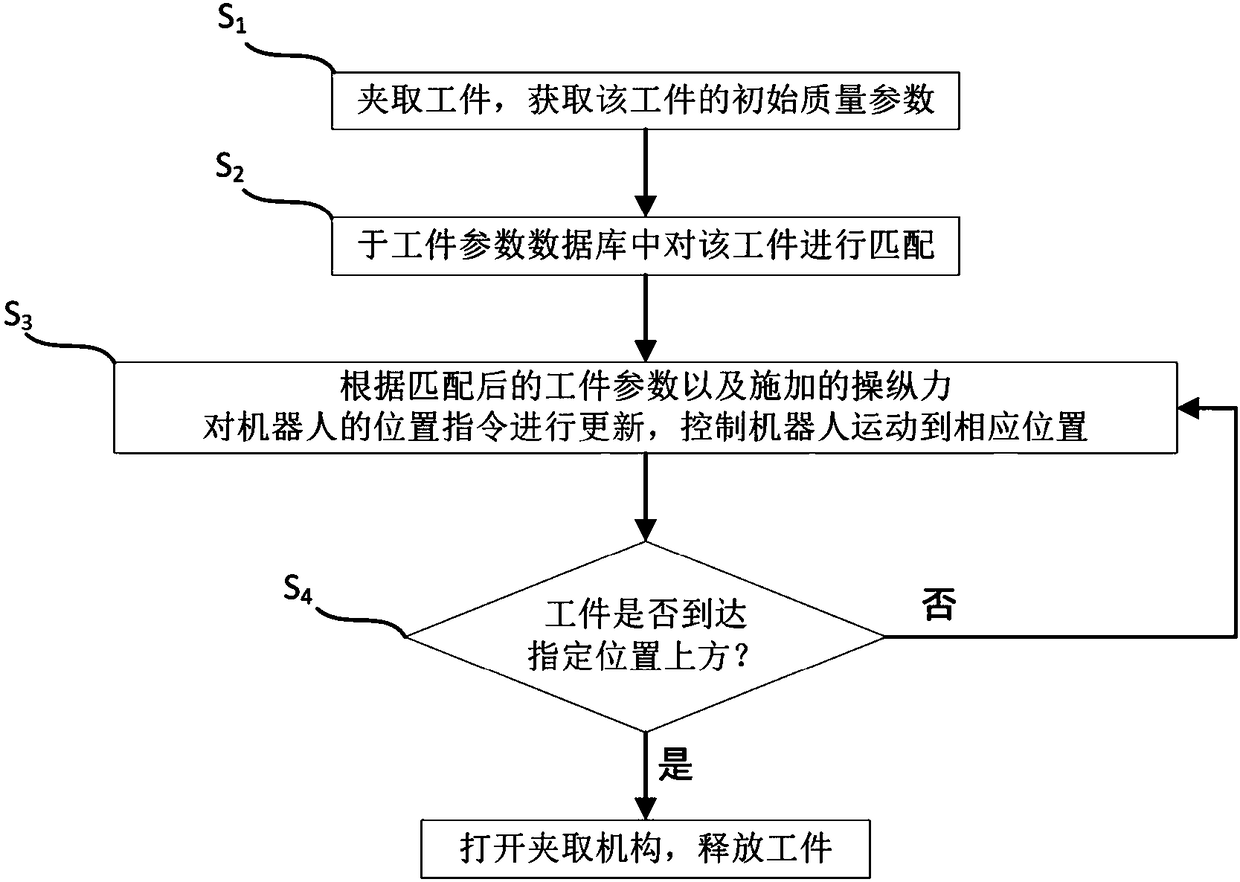

[0027] Such as figure 1 As shown, this embodiment relates to a robot-assisted operation system, which is used to control the robot to assist humans to complete operations such as handling, assembly, and positioning, including:

[0028] The man-machine cooperative operation unit 1 is used to input the manipulation force to the flange end of the robot connected with the clamping mechanism;

[0029] A force sensing module 2, which is arranged at the end of the flange of the robot, is used to obtain the force situation at the end of the flange of the robot;

[0030] The database module 3 is used to store standard mechanical parameters of all workpieces, including standard quality parameters and standard center-of-mass parameters of workpieces;

[0031] The identification module 4 is used to identify the mechanical parameters of the clamped workpiece and match them with the stored standard mechanical parameters of the workpiece;

[0032] The position command module 5 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com