Novel graphite crystal derivation device

A graphite crystal and derivative technology is applied in the field of new graphite crystal derivatives, which can solve the problems of the adverse effect of diffraction effect and the fragility of graphite, and achieve the effect of eliminating the graphite cutting and bonding process, reducing loss and maintaining integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

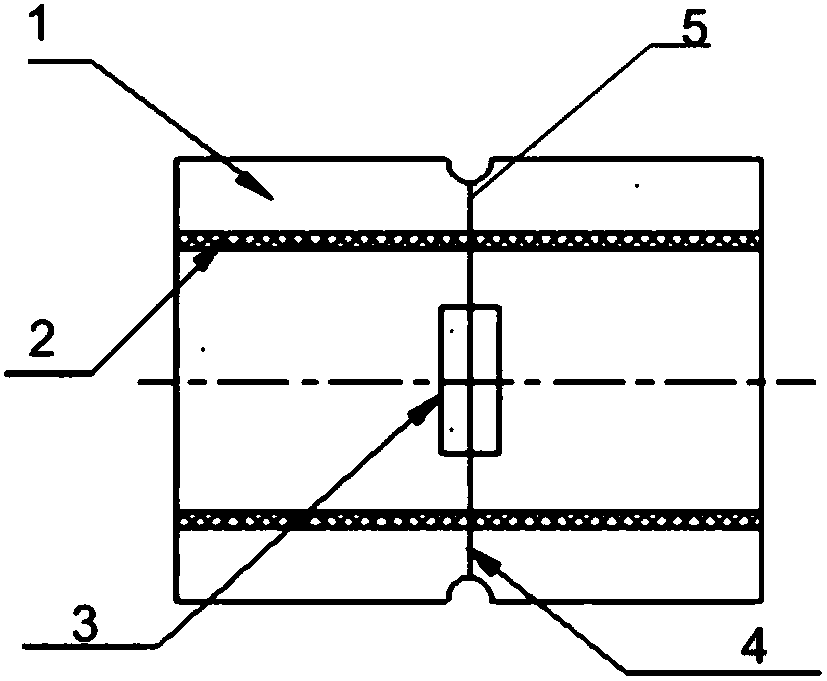

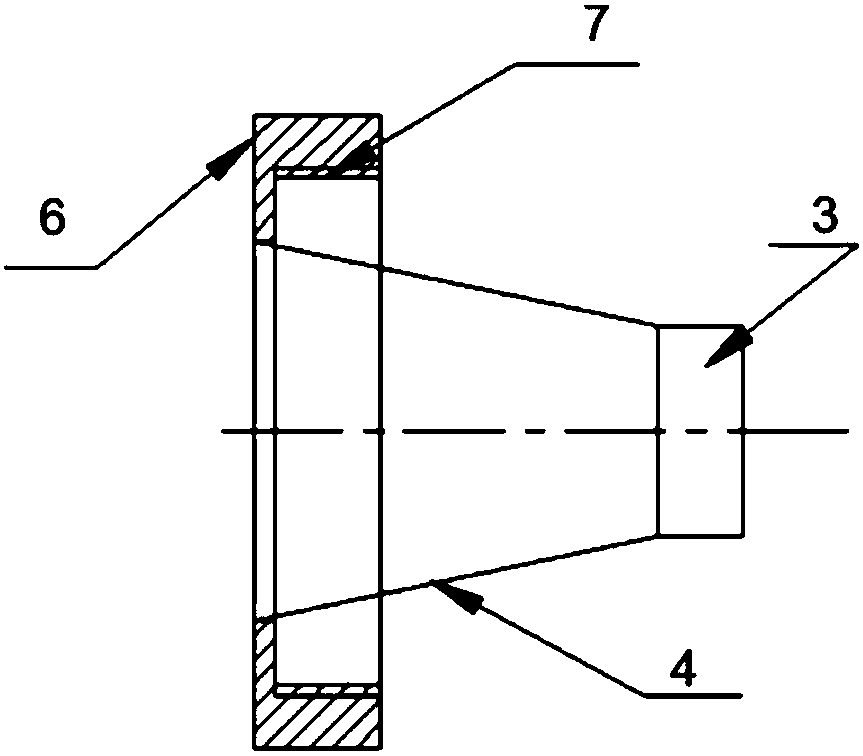

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] Such as figure 2 Shown, the invention provides a kind of novel graphite crystal derivative, comprise graphite crystal cylinder ( figure 2 not shown in), tungsten shielding core 3 and shielding core mounting cap 6; the graphite crystal cylinder is formed integrally with graphite crystal; the shielding core mounting cap 6 is detachably connected to the graphite crystal cylinder; the tungsten The shielding core 3 is fixedly connected to the shielding core installation cap 6 through the shielding core support wire 4, and after the shielding core installation cap 6 is connected to the graphite crystal cylinder, the tungsten shielding core 3 is placed in the graphite crystal cylinder central location.

[0022] The outer layer of the graphite crystal is provided with a casing (not shown in the figure), and the casing is detachably connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com