Foam ceramic high-temperature release agent and its application method

A technology of foamed ceramics and mold release agent, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of insufficient paper area and length, irregular corners of products, difficulty in sticking and fixing, etc., so as to improve the neatness of products , labor saving, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

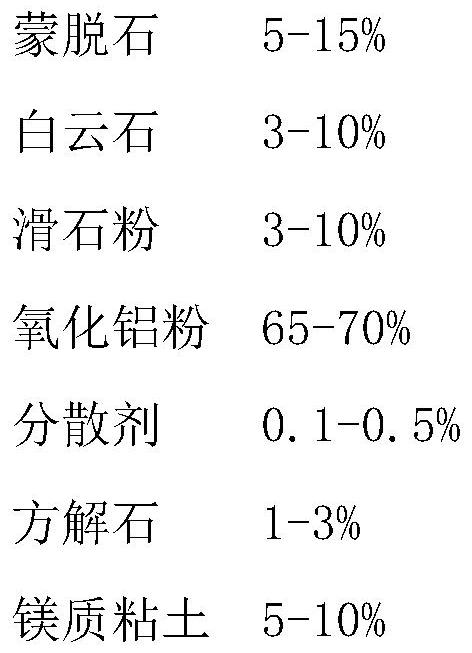

[0027] A high-temperature release agent for foamed ceramics, consisting of the following raw materials in mass fraction:

[0028]

[0029] The dispersant is a silane dispersant.

[0030] The particle size of each material is greater than 325 mesh.

[0031] Said materials are mixed evenly and then mixed with water, the mass ratio of mixing is material:water=3:7.

[0032] The foam ceramic high-temperature release agent is mixed with water, and after mixing, the mold is sprayed by spraying equipment, and the spraying thickness is 0.7mm.

[0033] The high-temperature release agent for foamed ceramics is mixed with water, and the mold is sprayed by spraying equipment after mixing. The sintering temperature of the sprayed coating is 910 degrees, while that of the foamed ceramics is 1100 degrees. The sprayed coating is sintered earlier than the foamed ceramics.

Embodiment 2

[0035] A high-temperature release agent for foamed ceramics, consisting of the following raw materials in mass fraction:

[0036]

[0037] The dispersant is a silane dispersant.

[0038] The particle size of each material is greater than 325 mesh.

[0039] Said materials are mixed evenly and then mixed with water, the mass ratio of mixing is material:water=3:5.

[0040] The foam ceramic high-temperature release agent is mixed with water, and after mixing, the mold is sprayed by spraying equipment, and the spraying thickness is 1mm.

[0041] The high-temperature release agent for foamed ceramics is mixed with water, and the mold is sprayed by spraying equipment after mixing. The sintering temperature of the sprayed coating is 930 degrees, while that of the foamed ceramics is 1150 degrees. The sprayed coating is sintered earlier than the foamed ceramics.

Embodiment 3

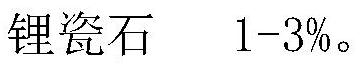

[0043] A high-temperature release agent for foamed ceramics, consisting of the following raw materials in mass fraction:

[0044]

[0045] The dispersant is a silane dispersant.

[0046] The particle size of each material is greater than 325 mesh.

[0047] Said materials are mixed evenly and then mixed with water, the mixing mass ratio is material:water=4:6.

[0048] The foam ceramic high-temperature release agent is mixed with water, and after mixing, the mold is sprayed by spraying equipment, and the spraying thickness is 0.9mm.

[0049] The high-temperature release agent for foamed ceramics is mixed with water, and the mold is sprayed by spraying equipment after mixing. The sintering temperature of the sprayed coating is 890 degrees, while that of the foamed ceramics is 1090 degrees. The sprayed coating is sintered earlier than the foamed ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com