Suspension vibration energy driving and braking system

A technology of vibration energy and braking system, which is applied in the direction of auxiliary drive devices, control devices, machines/engines, etc., can solve the problems of flywheel energy waste and inerters not being able to achieve vibration isolation, etc., to improve ride comfort and handling Stable, high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

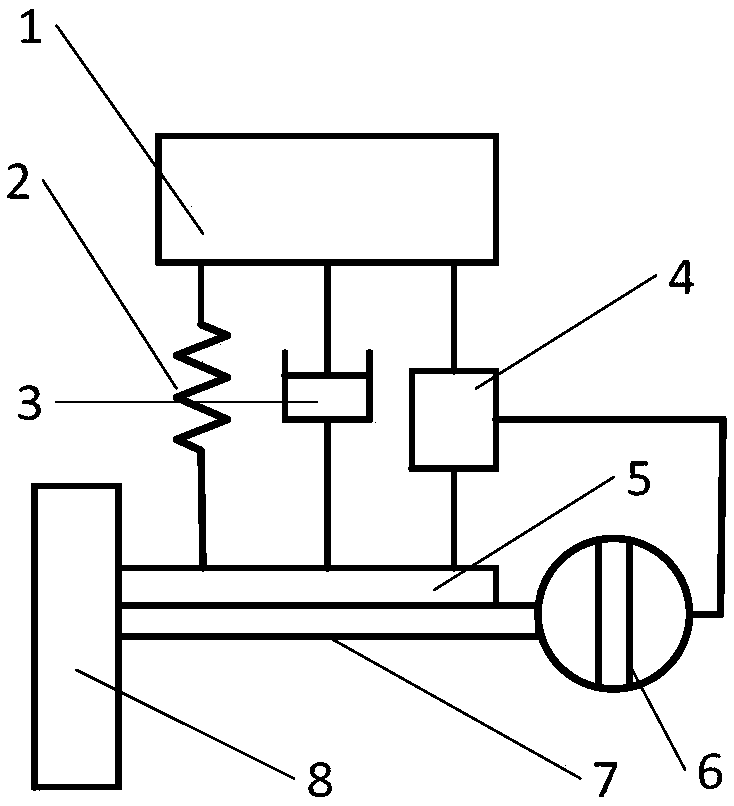

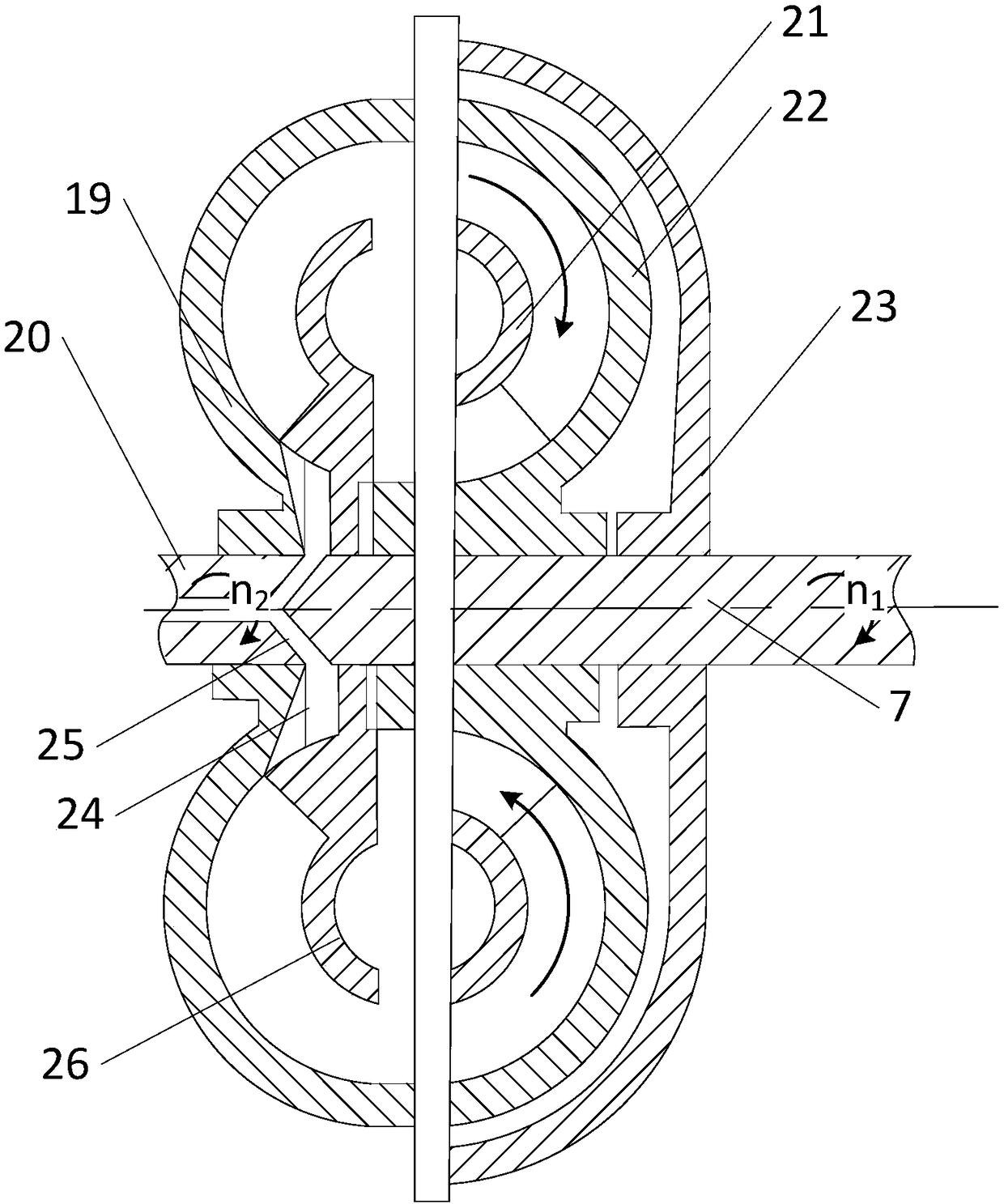

[0024] like figure 1 As shown, the suspension vibration energy driven braking system of the present invention includes an inerter assembly 4, a hydraulic motor coupling assembly 6 and a drive shaft 7; the inerter assembly 4, spring element 2 and damping element 3 are respectively installed on Between the vehicle body 1 and the swing arm 5; the hydraulic motor coupling assembly 6 includes a hydraulic motor 18 and a coupler assembly, the input transmission shaft 20 of the hydraulic motor 18 is connected to the coupler assembly, and the output end of the coupler assembly is connected to the drive shaft 7 for torque transmission; the drive shaft 7 is connected with the wheel 8.

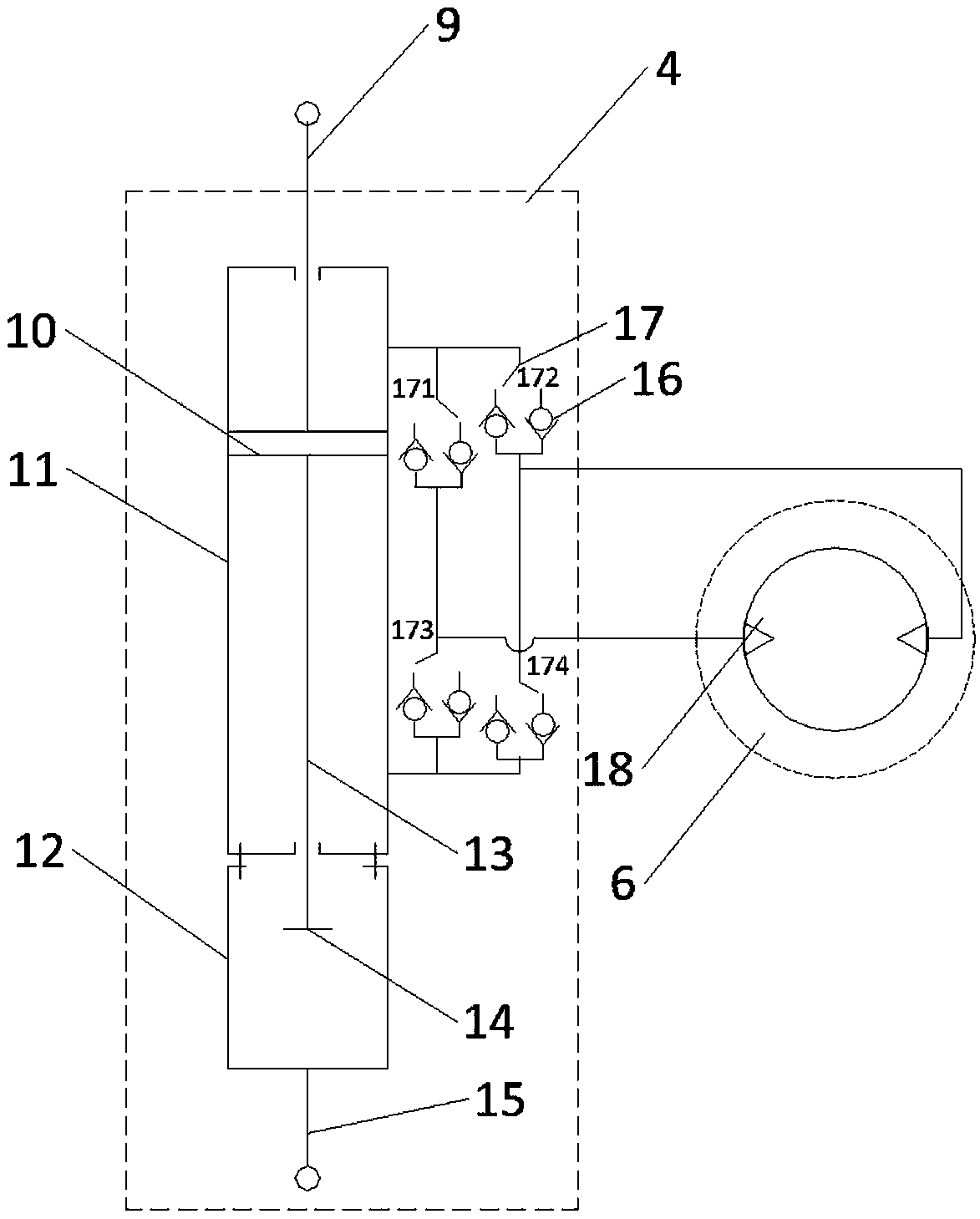

[0025] like figure 2 As shown, the container assembly 4 includes a double piston rod cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com