Damping anti-rolling tank with tunable mass

A technology of tuning mass and damping, which is applied in the direction of reducing ship motion through displacement, liquid shock absorbers, etc., can solve the problems of raising the center of mass of the platform, increasing the cost of anti-rolling, and not matching the frequency range, so as to ensure the anti-rolling performance , the effect of high-efficiency anti-rolling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

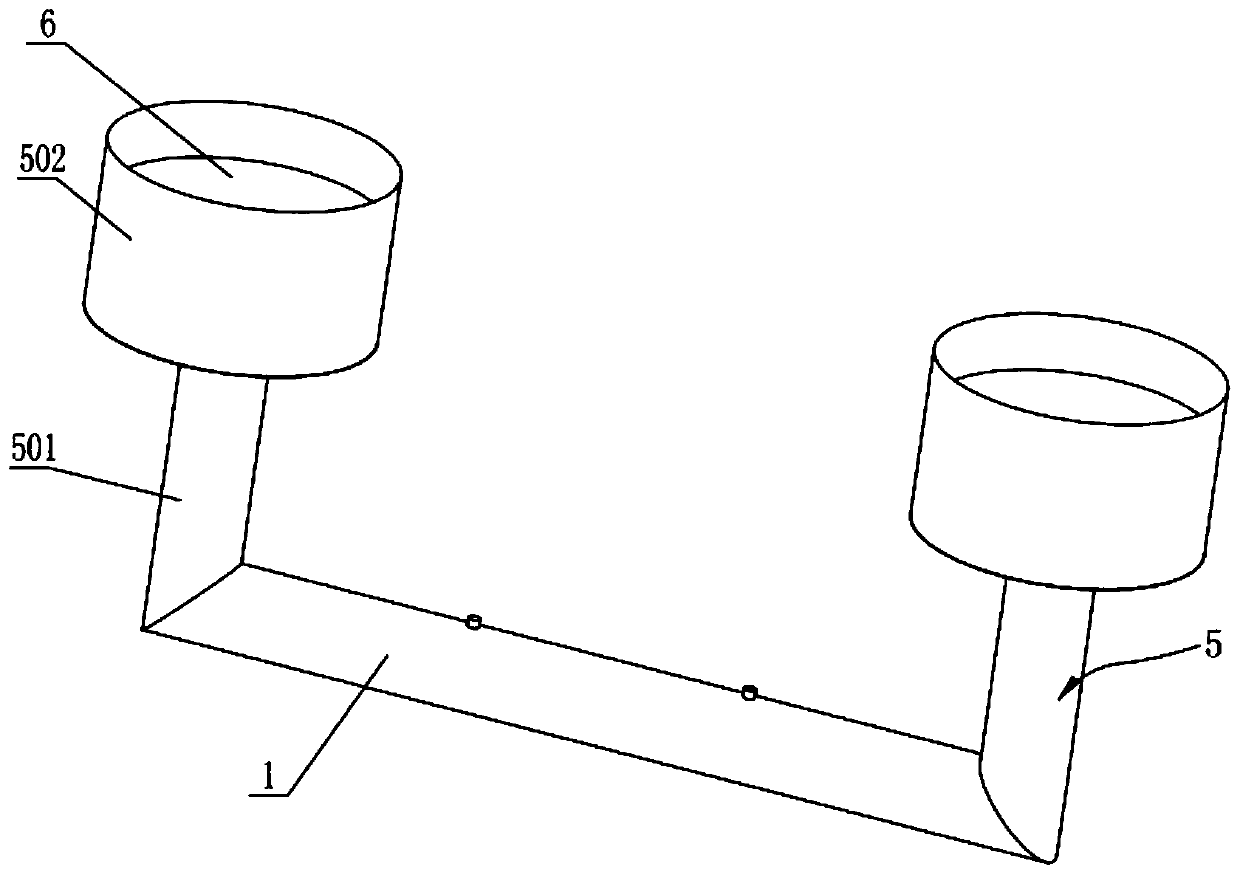

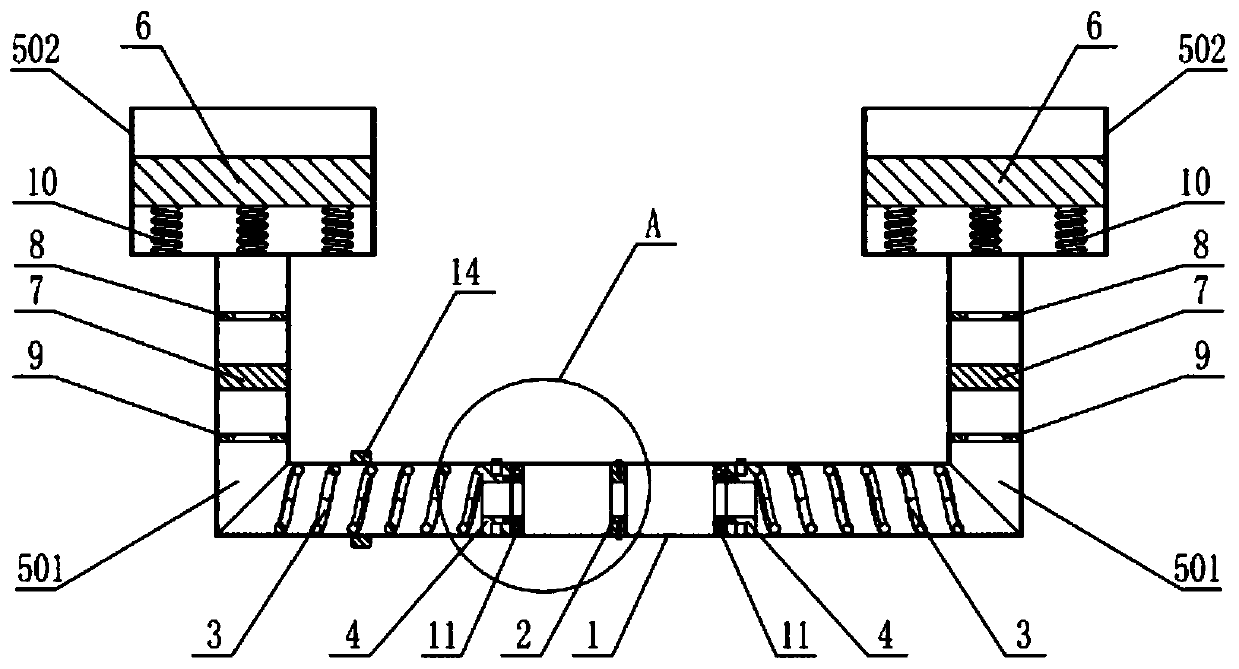

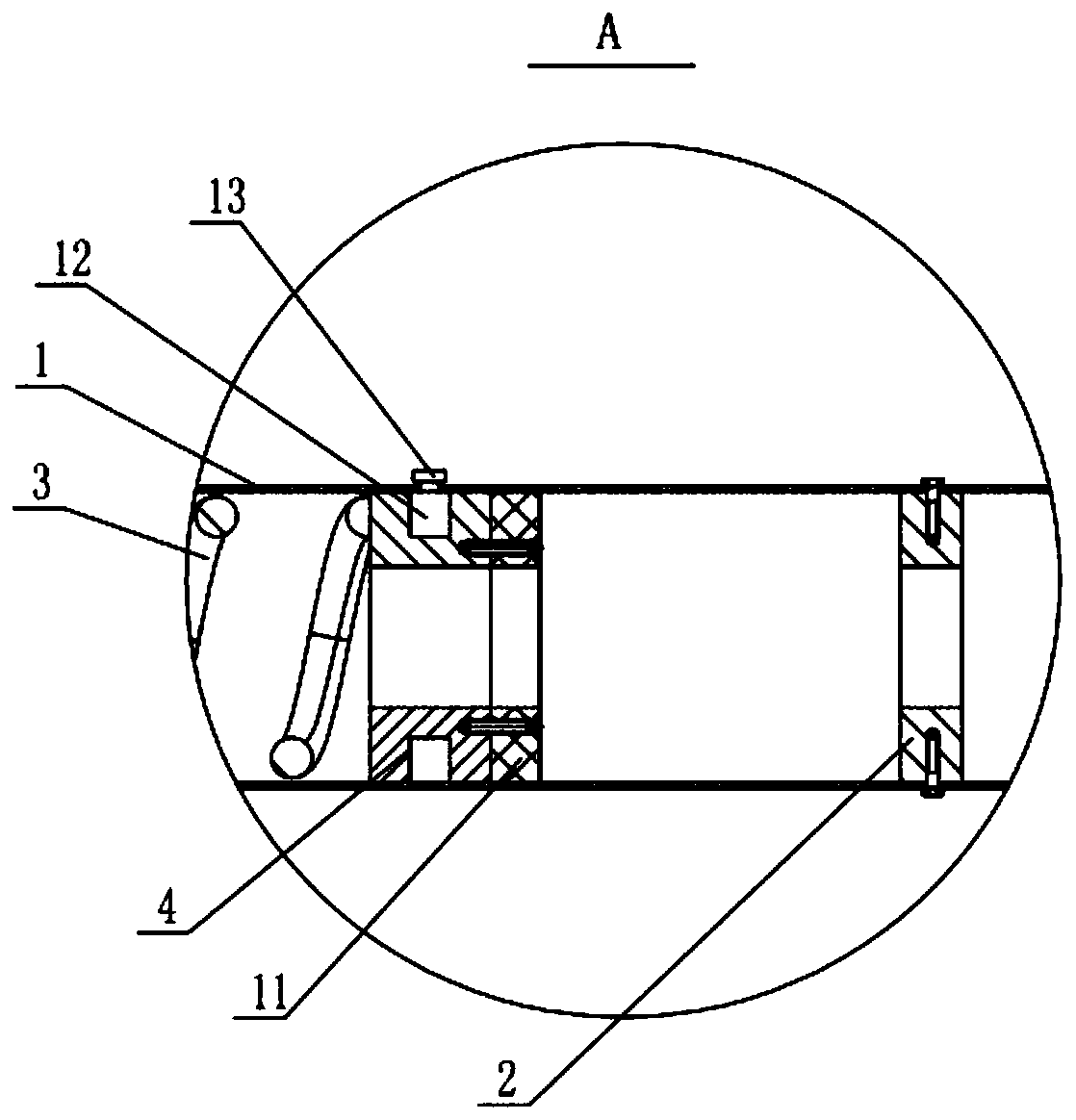

[0019] See figure 1 , figure 2 , image 3 , the damping anti-rolling water tank with adjustable mass in the present invention includes a U-shaped tank, the bottom of the U-shaped tank is a horizontal pipe section 1, and the two sides of the U-shaped tank are two riser sections 5, The horizontal pipe section 1 communicates with the standpipe section 5; the horizontal pipe section 1 of the U-shaped box is fixed with a limit ring-2, and the limit ring-2 is preferably arranged in the middle of the horizontal pipe section 1, and the limit ring-2 A pair of horizontal springs 3 are arranged symmetrically on both sides. One end of the two horizontal springs 3 towards the limit ring 2 is respectively connected to a mass block 4. The other end of the horizontal spring 3 is connected to the inner wall of the horizontal pipe section 1. Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com