Laser welding equipment welding test bench

A laser welding and test bench technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high cost, high welding defect rate, low welding test efficiency, etc., achieve smooth welding wire, improve reliability, The effect of reducing scrap rate and test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

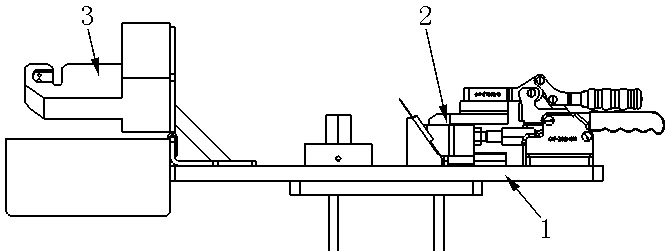

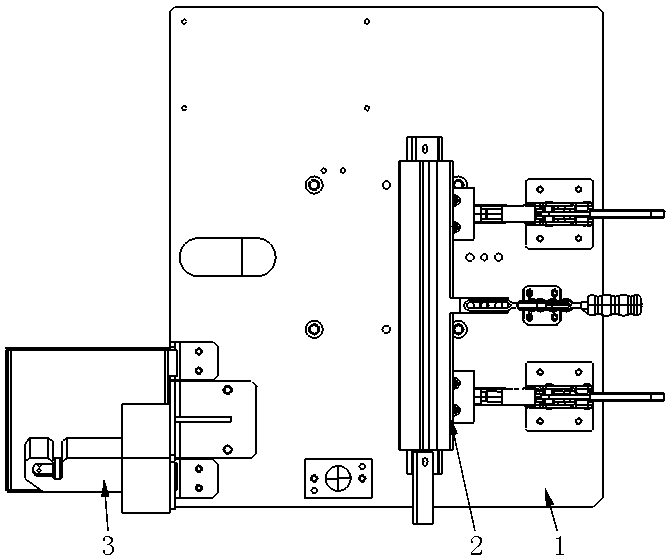

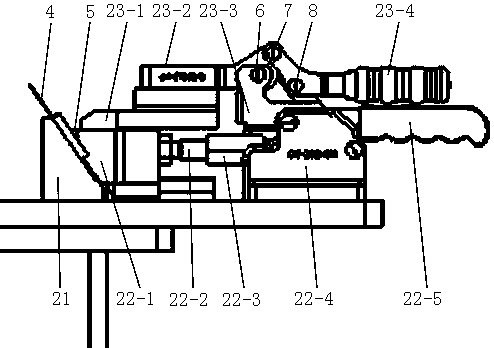

[0029] Figure 1 to Figure 4 The laser welding equipment welding test bench shown mainly includes a machine platform 1, a test piece fixing mechanism 2 and a wire cutting mechanism 3 installed on the machine platform 1, wherein the test piece fixing mechanism 2 is used to fix the flat surface of the body welding test piece. The test piece 4 and the bending test piece 5 ; the test piece fixing mechanism 2 includes a test piece placement table 21 , a lower clamping device 22 and a bending fixing device 23 . like Figure 4 and Figure 5 As shown, the test piece placement platform 21 is a long wedge, and the length of the long wedge is greater than the length of the test piece. The wedge surface of the long wedge includes an upper wedge surface 21-1 and a lower wedge surface 21-3, and the upper wedge surface 21- 1 and the lower wedge surface 21-3 are sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com