Big data monitoring system applied to production workshop

A technology for monitoring systems and production workshops, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as low work efficiency and low degree of automation in production workshops, and facilitate production capacity adjustment, inspection and analysis of welding Data, the effect of optimizing welding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

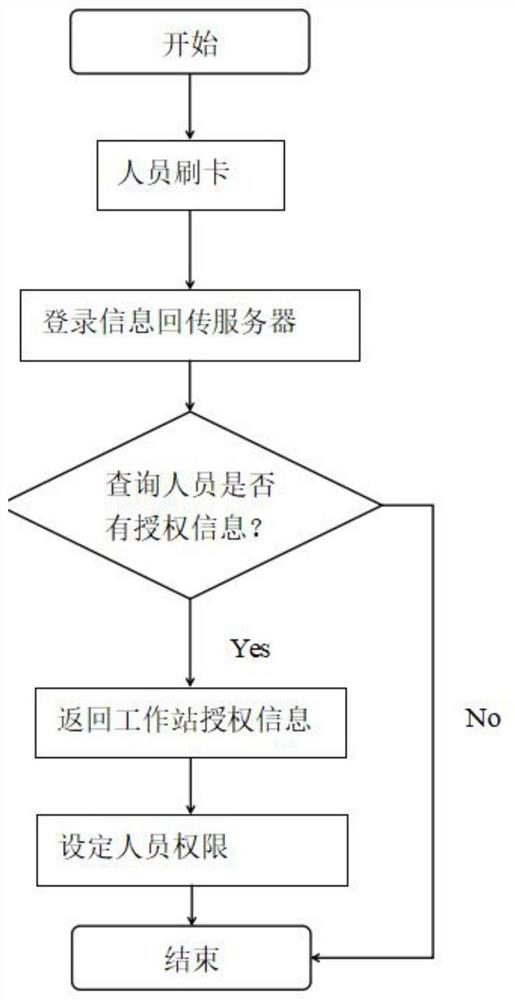

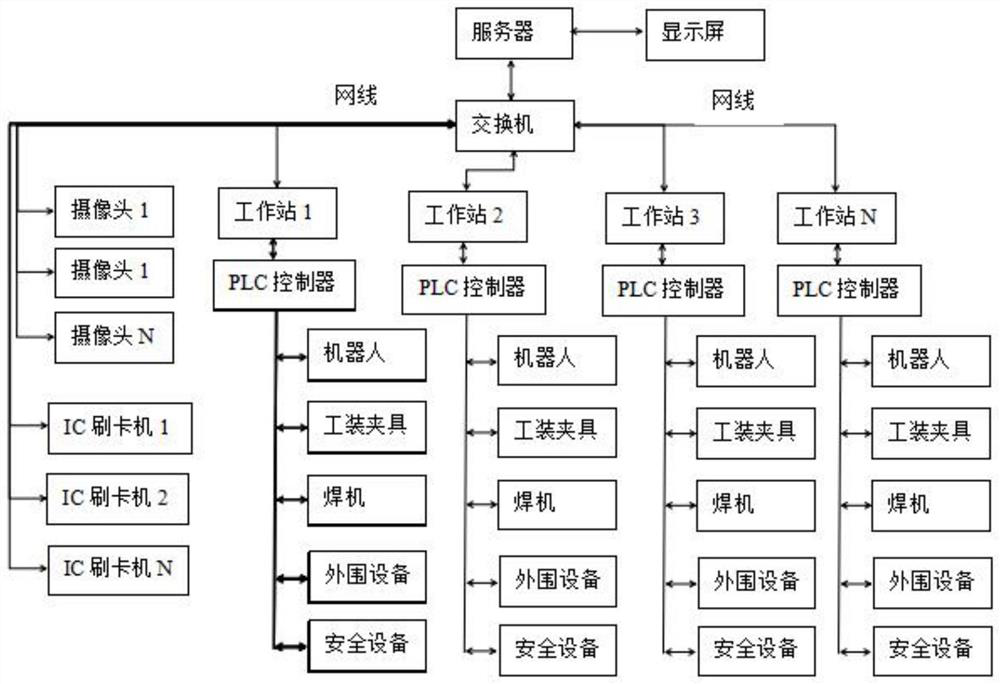

[0025] Such as Figure 1-3 As shown, the embodiment of the present invention provides a big data monitoring system applied to a production workshop, including a management system and a data acquisition system connected to each other through a network, the data acquisition system includes a server, the server is electrically connected to the display screen, and the server is used for For data collection, storage and analysis, the server terminal is equipped with a switch, and the server terminal is electromechanically connected with several workstations, several cameras, and several IC card swiping cards through the network to collect data for welding production equipment.

[0026] Workstations include Workstation 1, Workstation 2, Workstation 3,..., Workstation N, all of which are electrically connected to the PLC controller. Several cameras include Camera 1, Camera 2,..., Camera N, and several IC card readers include IC card reader 1, IC card reader 2, ..., IC card reader N. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com