A friction stir welded integral wall plate and its production method

A friction stir welding and integral siding technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems affecting the mechanical properties and corrosion resistance of aluminum alloy siding, cracks, and easy occurrence of pores. Excellent mechanical properties and corrosion resistance, the effect of optimizing welding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

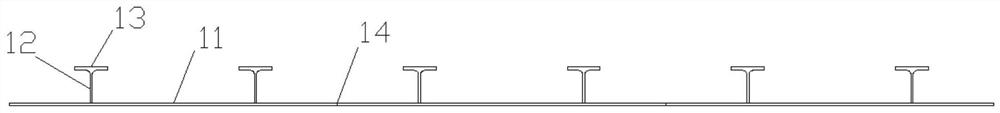

[0061] Embodiment 1 of the present invention provides a production method of a friction stir welded integral wall plate, comprising the following steps:

[0062] (1) Plate pretreatment: Before friction stir welding, the 5E61 ribbed plate is subjected to stabilization heat treatment, followed by intermediate annealing → flattening, straightening → stabilization annealing operations.

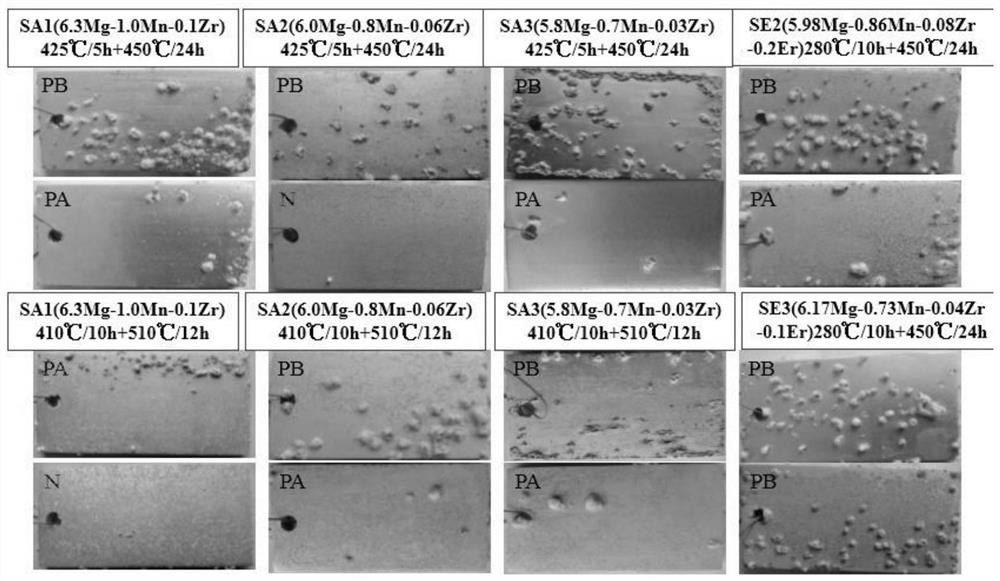

[0063] Intermediate annealing, annealing at a temperature of 280-425°C for 5-10 hours; after the temperature drops below 50°C, flatten and straighten it, and control the stretching rate at 0.5-1.0%, if necessary, carry out secondary stretching , the cumulative elongation rate shall not exceed 1.5%; the 5E61 ribbed sheet shall be annealed at 450-510°C for 12-24 hours. The pretreatment conditions are shown in Table 1.

[0064] Table 1 Samples prepared under different pretreatment conditions

[0065]

[0066] (2) Friction stir welding: Align and fix the pretreated 5E61 ribbed plates in the lengt...

Embodiment 2

[0075] The preparation method is the same as that of sample SE3 in Example 1, except that this example involves the influence of welding parameters on the mechanical properties of the friction stir welded integral wall plate. The different welding parameters are shown in Table 4, and the mechanical properties of the friction stir welded monolithic panels prepared under different welding parameters are shown in Table 5. The mechanical properties of the overall panel are shown in Table 6.

[0076] Table 4 Different welding parameters

[0077] craft mixing head Speed(r / min) Welding speed (mm / min) Craft one double helix 1000 800 Craft Two triple helix 1000 600 Craft Three double helix 1000 700 Craft Four double helix 800 600 Craft five single ring 1100 400

[0078] Table 5 Mechanical properties of friction stir welded monolithic panels prepared under different welding parameters

[0079]

[0080]

[0081] Tab...

Embodiment 3

[0085] The preparation method is the same as that of sample SE3 in Example 1, the difference is that this example studies the influence of different welding processes on the mechanical properties of the overall wall plate, and the results are shown in Table 7.

[0086] Table 7 Effects of different welding processes on the mechanical properties of integral panels

[0087]

[0088]

[0089] Table 7 shows that the tensile strength of the integral wall plate prepared by the friction stir welding process is significantly better than that of the automatic TIG flat welding integral wall plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com