Flat panel detector and its preparation method

A flat-panel detector and planarization layer technology, applied in the field of flat-panel detectors and its preparation, can solve problems affecting product yield, affecting factory production capacity, and complicated preparation process, so as to reduce the use of MASK, high photoelectric conversion efficiency, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in detail below. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The reagents or instruments used were not indicated by the manufacturer, and they were all commercially available conventional products.

[0023] The present invention is based on the following knowledge and findings of the inventors:

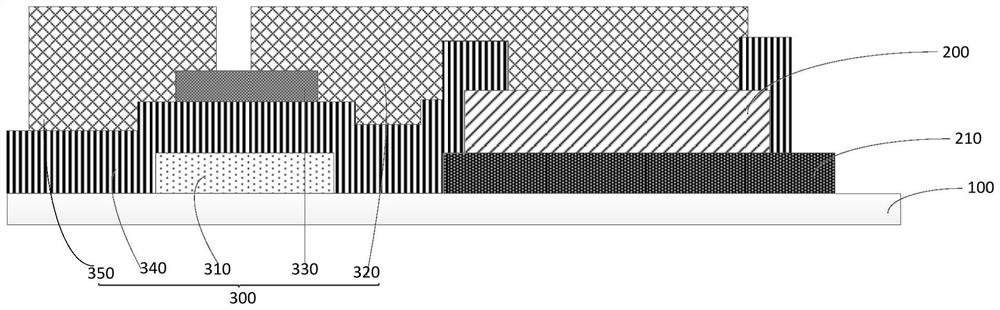

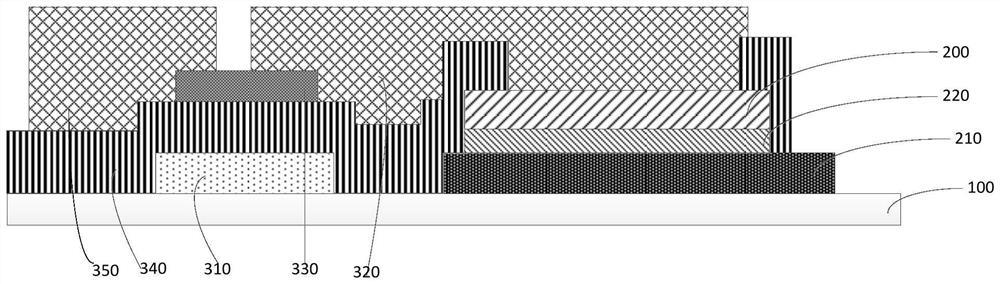

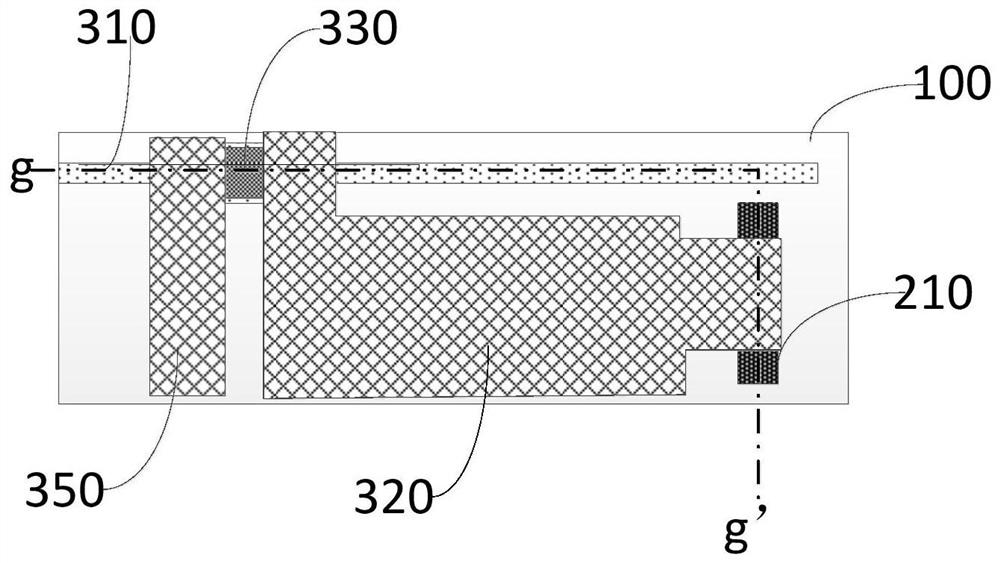

[0024] At present, the structure of the flat panel detector is relatively complicated. In the preparation process, the thin film transistor is usually prepared first, and then the photoelectric conversion film layer is prepared. The preparation steps are relatively cumbersome, and more times of MASK or more m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap