Scalable electric generator

A technology of generators and generator discs, which is applied in the direction of controlling generators, engines, wind power generation, etc., and can solve problems such as improvement, impractical feasibility, and multi-power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

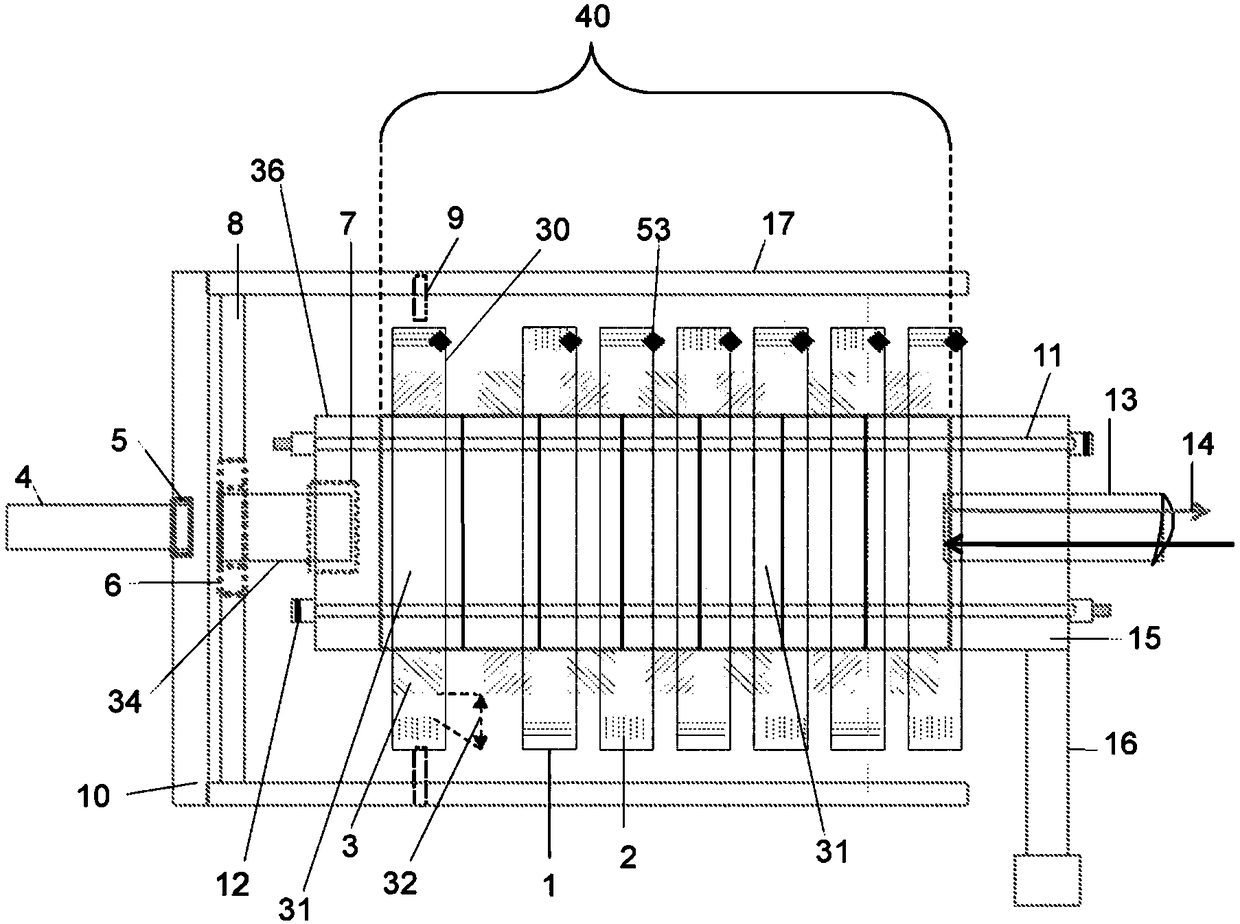

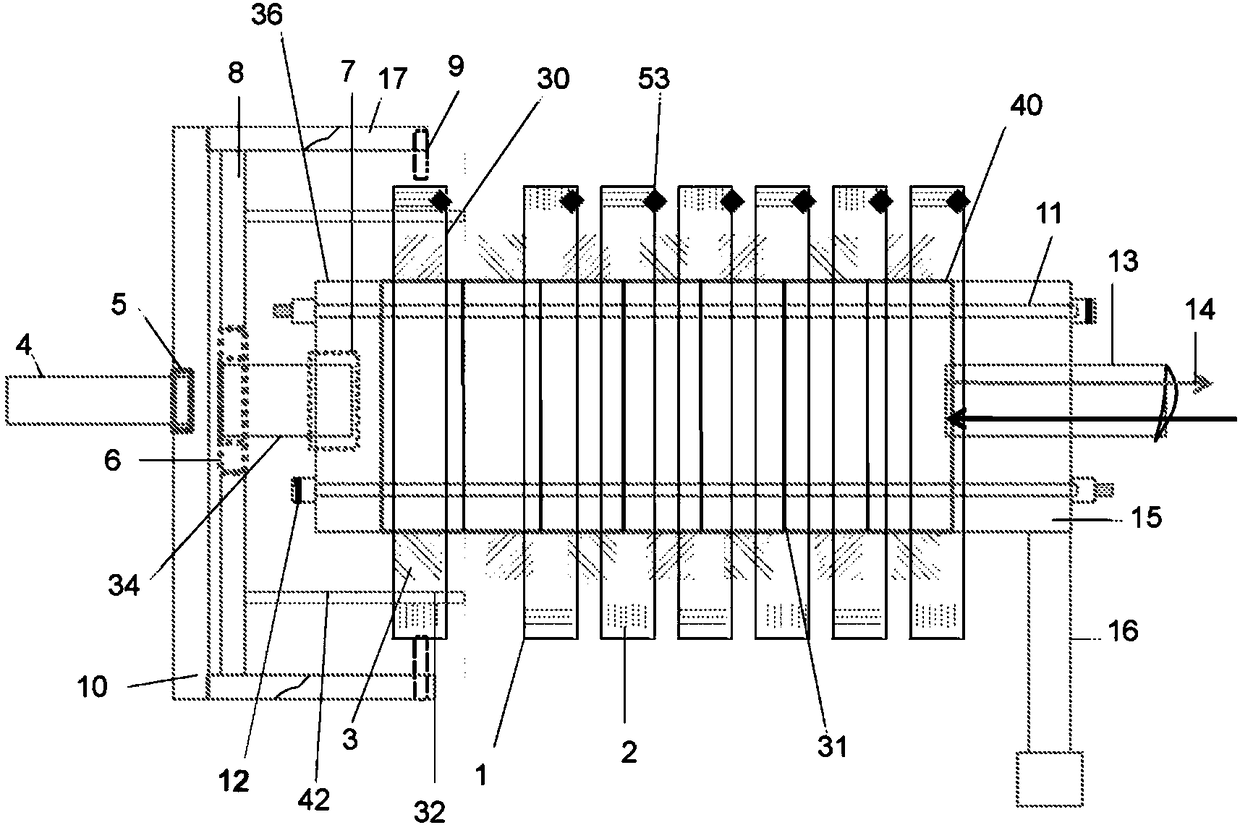

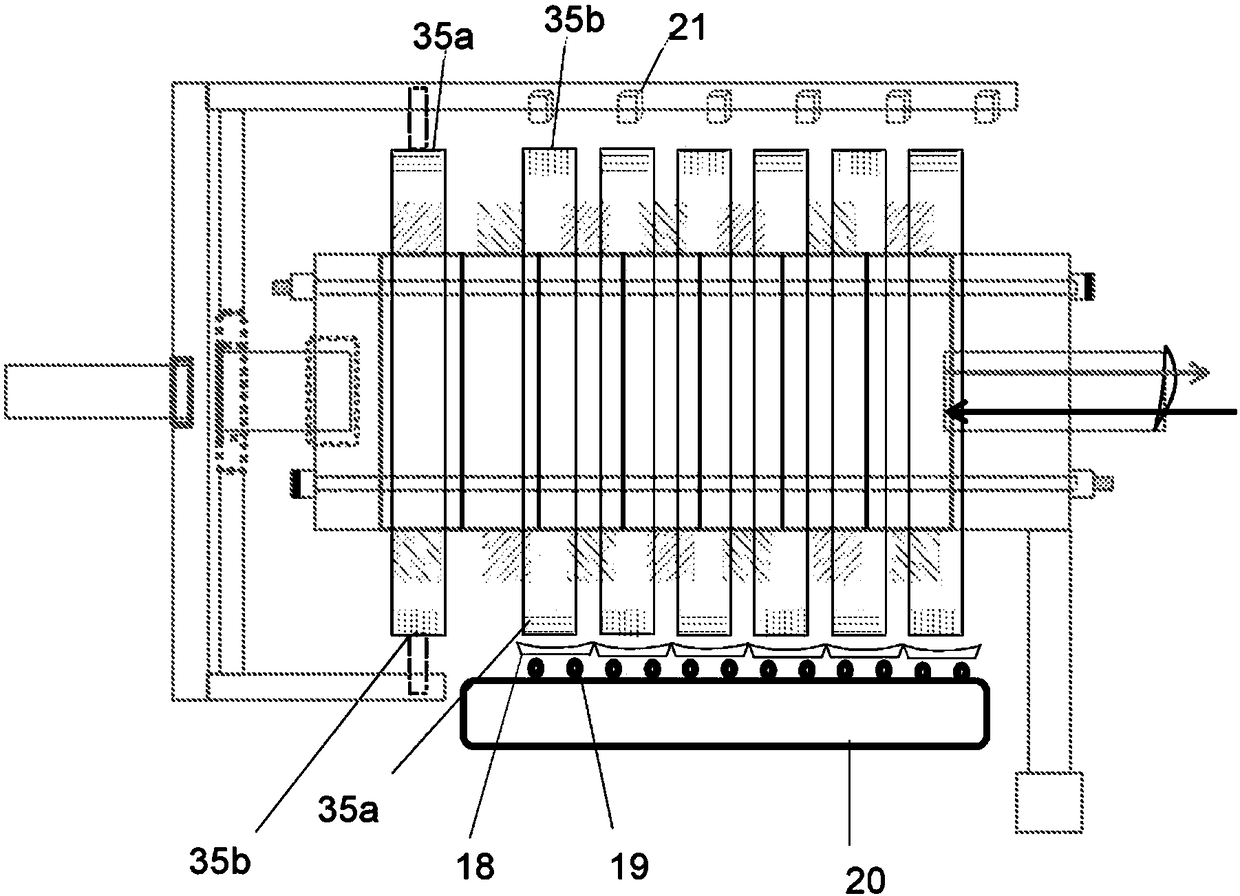

[0033] With reference to accompanying drawing 1-Fig. 10, in Figure 1A and Figure 1B A generator disc assembly 30 according to the present invention is shown in , and is shown in, for example Figure 101a A cross-sectional view of the same generator disc assembly is shown in . In one embodiment, components and structures can be compared with those in Figure 101- Figure 107 The same motor assembly as described in . The rotor ring / frame 1 comprises pairs of magnets 2, wherein the magnets 2 are arranged inwards on the inner surface of the rotor ring 1, and the magnets may be any type of suitable magnets / electromagnets. The rotor ring 1 is arranged on the outside of the armature assembly 3, 31, 104, 106, 105, which includes the stator frame, the stator poles protruding outwards and the corresponding wire windings on the stator poles, so that when current is applied to the windings When the magnetic flux is polarity defined by the winding direction. The inwardly facing magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com