Aromatherapy machine with rotating structure

A rotating structure and aromatherapy technology, which is applied in the field of atomization technology, can solve the problems of unfavorable aroma emission, large amount of mist, waste of perfume, etc., to prevent small water droplets from spraying out with water mist, expand the space, and facilitate aroma emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

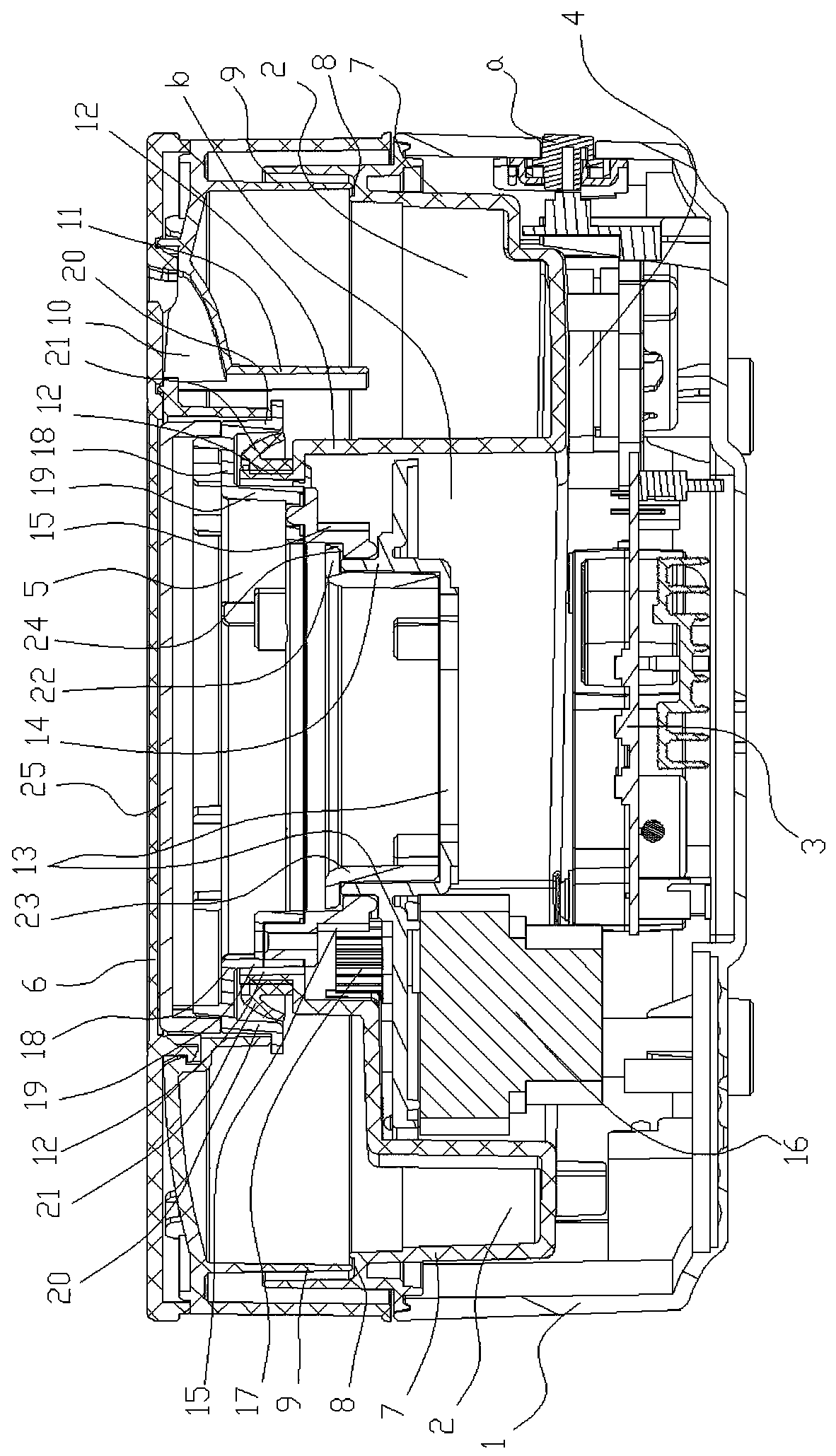

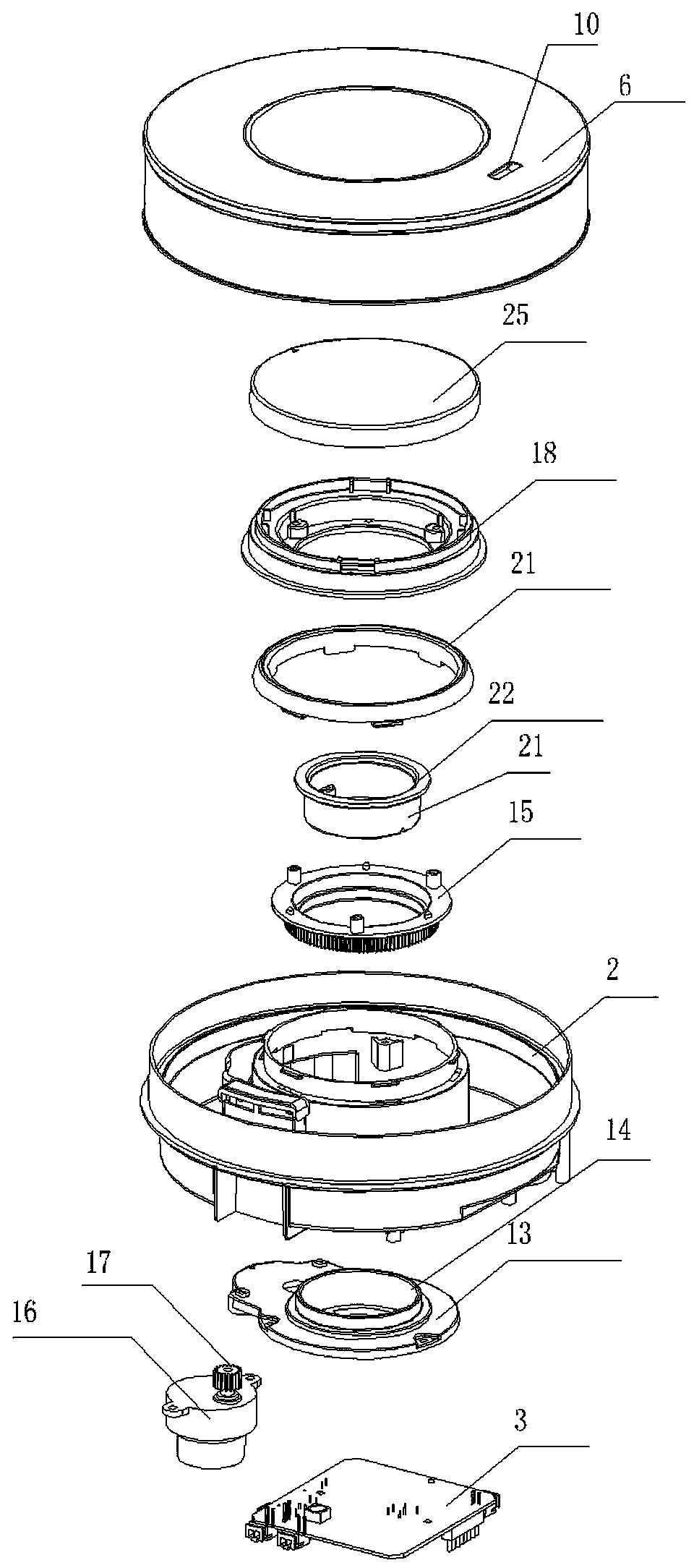

[0012] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0013] Such as figure 1 , 2 As shown, the present invention comprises a casing 1 with a control button a, an annular sink 2 arranged in the casing 1, a circuit board 3 (control device) arranged in the casing 1 below the sink 2, and a The atomizer 4 (ultrasonic generator) at the bottom of the water tank 2, the rotating table 5 driven by electric power provided on the perforation b in the middle of the circular water tank 2, the cover 6 provided on the rotating table 5, and the The upper end of the outer groove wall 7 of 2 is provided with an annular groove 8 with a notch upward, and an annular water retaining wall 9 is arranged under the cover 6 corresponding to the annular groove 8, and the bottom surface of the annular water retaining wall 9 extends Into the annular groove 8, the cover 6 is provided with a mist outlet 10 connected with the annular water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com