Intelligent composite slicer

A slicing machine, intelligent technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of cumbersome production cost, unsynchronized pressing roller mechanism and traction mechanism, unwinding and winding wrinkles, etc. Achieve the effect of improving cutting quality, being conducive to slitting and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

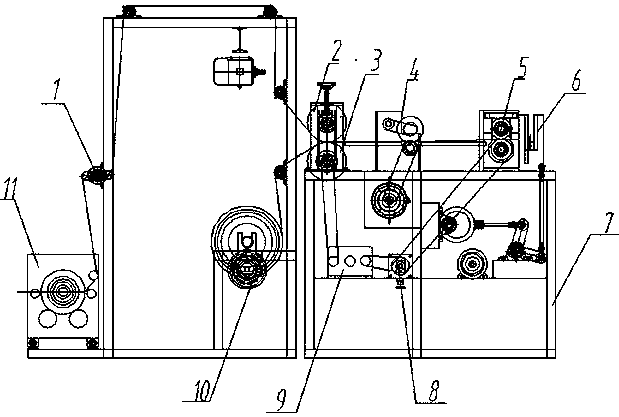

[0018] Such as figure 1 The described intelligent compound slicer includes a frame 7, on which a fabric unwinding device 11 and a release paper unwinding device 10 are arranged, and a pressing roller device and a slitting device are also arranged on the frame 7 Device 4, traction device 5 and upper and lower straight cutter device 6.

[0019] The fabric unwinding device 11 is provided with a fabric roll for fabric unwinding. In this embodiment, the fabric unwinding device has an automatic deviation correction mechanism, so that automatic deviation correction can be performed during unwinding. The fabric is sent to the pressure roller device through the cloth expander 1 and several guide rollers set on the frame. After the release paper is unrolled by the centrifugal unwinding device, it is also sent to the pressure roller device through several guide rollers. And after the release paper is heat-compressed and compounded by the pressing roller device, it is pulled by the traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com