Separating and brushing integrated machine gripper

An all-in-one machine, one-to-one technology, applied in the field of hand-splitting all-in-one machines, can solve problems such as damage to workers' health, high labor costs, and slow work efficiency, and achieve reduced floor space, reduced purchase costs, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The all-in-one machine for cutting and brushing is a common equipment in the battery industry, which is used to cut and brush tabs.

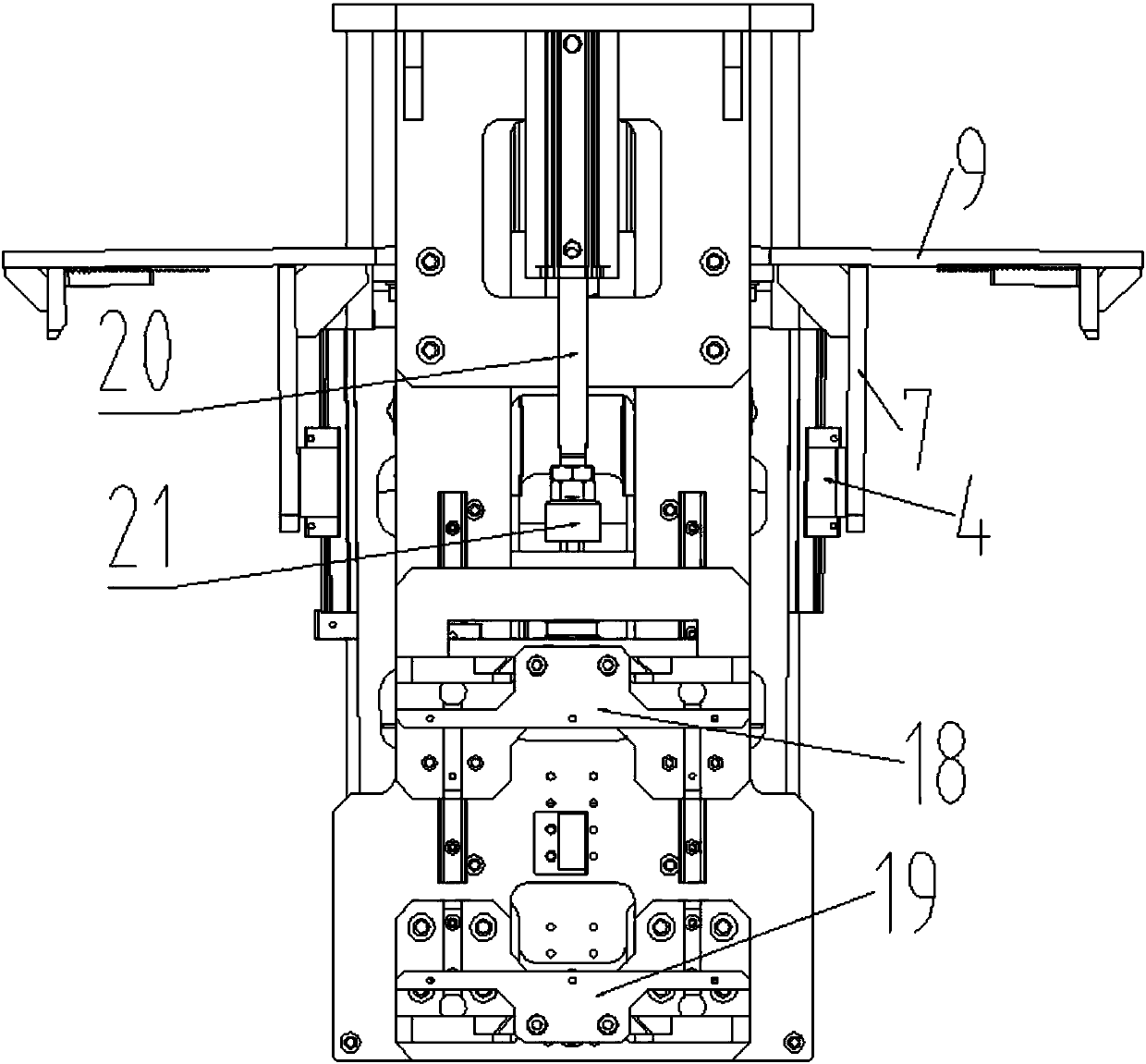

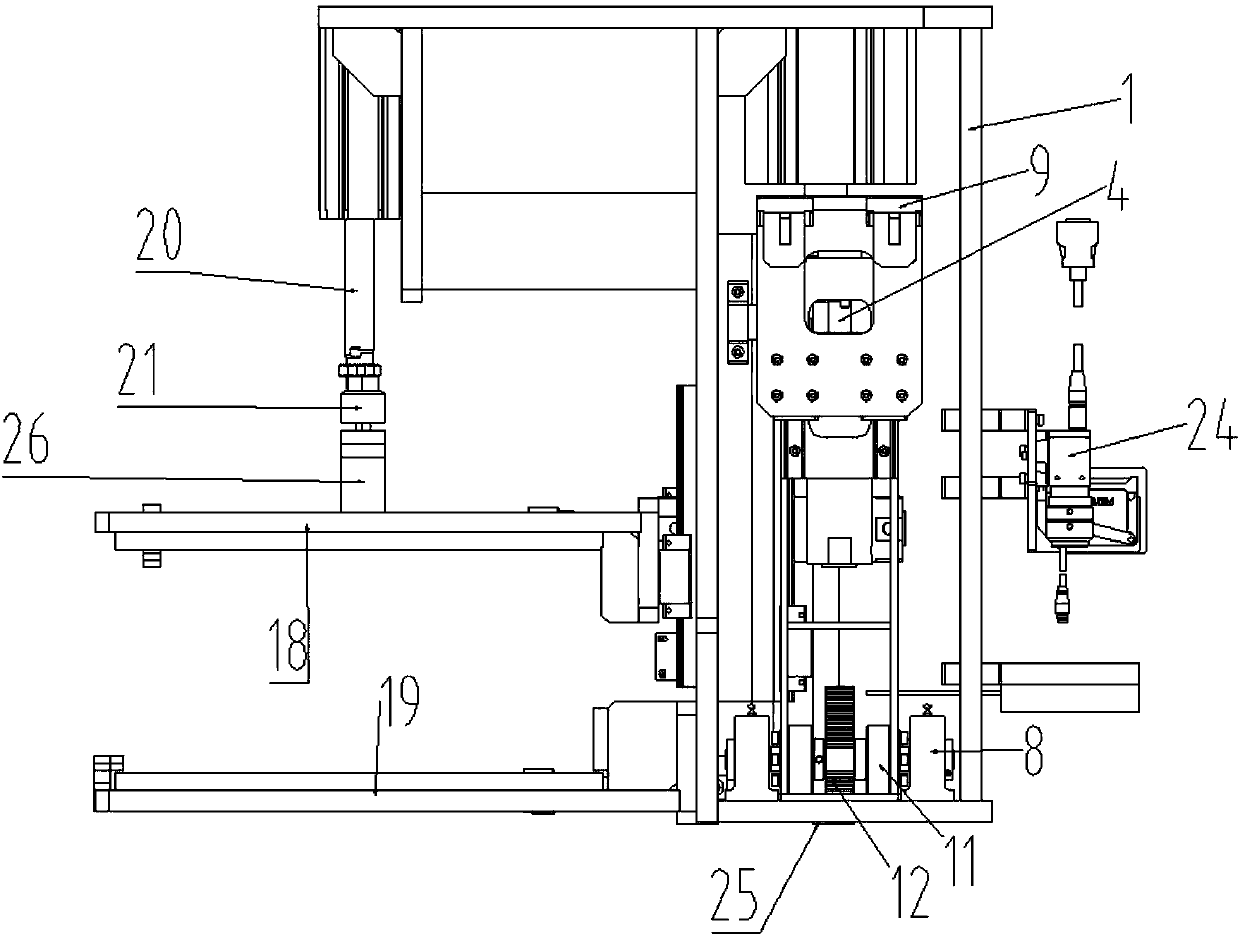

[0028] Such as figure 1 , figure 2 and image 3 As shown, the handle of the all-in-one machine for separating and brushing includes a bracket 1 , a curing rack handle 2 , an electrode plate handle 3 , a first driving mechanism 4 , a second driving mechanism 6 and a controller 5 .

[0029] The curing rack gripper 2 is used to grasp the curing rack.

[0030] The pole plate gripper 3 is used to grasp the pole plate.

[0031] The first driving mechanism 4 is used to drive the gripper 2 of the curing rack to complete the action of picking and placing the curing rack.

[0032] The second driving mechanism 6 is used to drive the electrode plate gripper 3 to complete the action of picking and placing the electrode plate.

[0033] The controller 5 controls the first driving mechanism 4 and the second driving mechanism 6 respectively.

[003...

Embodiment 2

[0037] As shown in Embodiment 1, this embodiment is a further limitation on the gripper 2 of the curing rack.

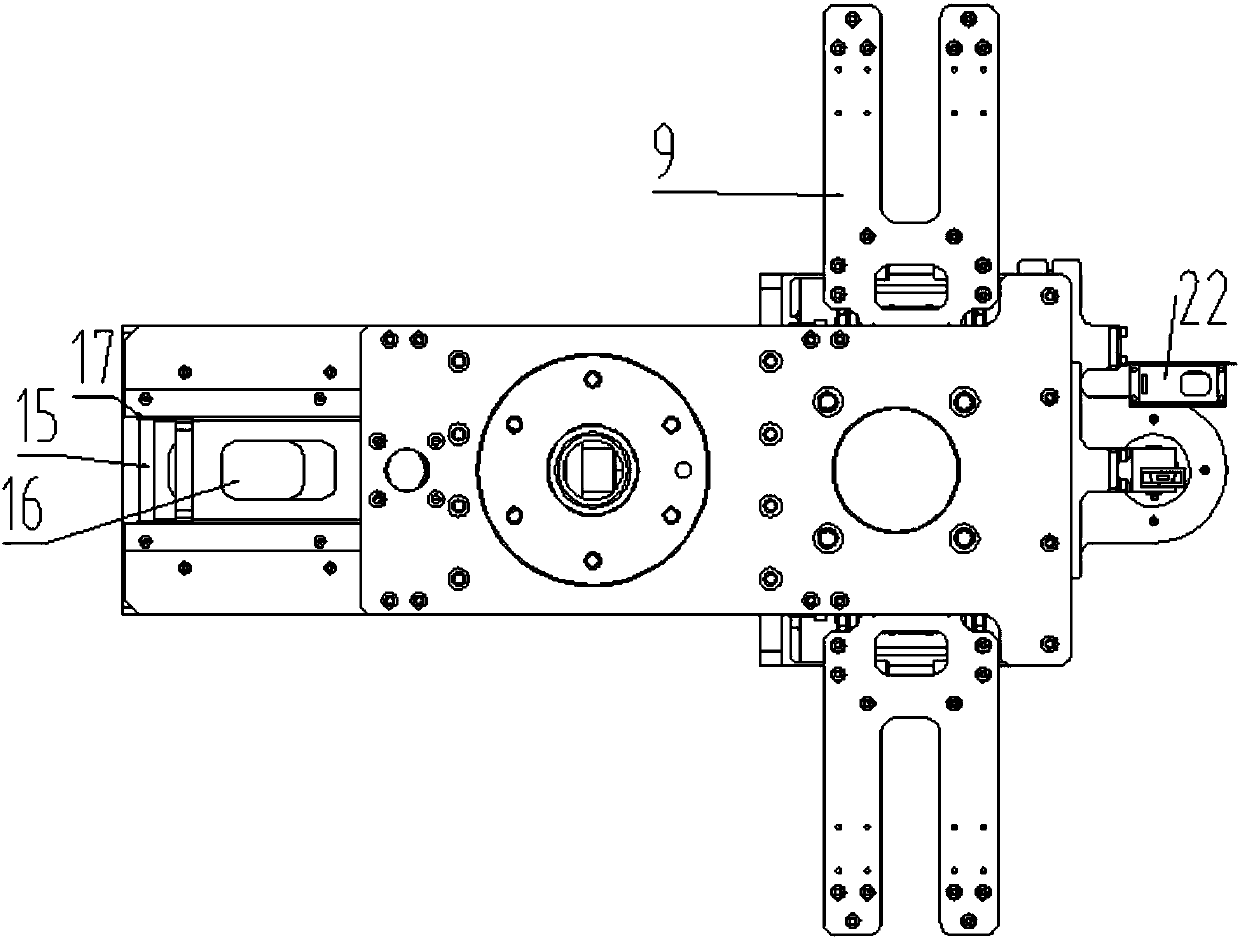

[0038] The gripper 2 of the curing rack in this embodiment includes a clamp arm 7 , and a rotating shaft 8 is provided on the support 1 , and the clamp arm 7 is connected to the support 1 through the rotating shaft 8 .

[0039] A chuck 9 is arranged on the clamp arm 7 , and the first driving mechanism 4 drives the chuck 9 to reciprocate on the clamp arm 7 . Chuck 9 is L or type. Chuck 9 is also provided with clamping mouth, when grabbing the curing rack that is provided with connecting block, the connecting block on the curing rack is inserted in jaw, improves the firmness of grasping curing rack. A guide rail may also be provided on the clamp arm 7, and the first driving mechanism 4 drives the collet 9 to move on the guide rail.

[0040] When the gripper of the brush-distributing machine is grabbing the curing frame, the controller 5 controls the first driving m...

Embodiment 3

[0042] As shown in Embodiment 2, the clip arm 7 of the present invention may be fixedly connected to the bracket 1 through the rotating shaft 8 , or may be rotatably connected to the bracket 1 through the rotating shaft 8 . This embodiment is a further limitation on the connection relationship between the clip arm 7 and the bracket 1 .

[0043] The clip arm 7 of this embodiment is rotatably connected to the bracket 1 through a rotating shaft 8 . The bracket 1 is provided with a third driving mechanism 10 for driving the clamp arm 7 to expand or contract. The third drive mechanism 10 communicates with the controller 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com