Preparation process and application of polydimethylsiloxane/graphene oxide porous composite material

A polydimethylsiloxane, porous composite material technology, applied in chemical instruments and methods, immiscible liquid separation, liquid separation, etc., can solve the problem of poor mechanical performance and cycle performance, harsh preparation process, and limited practical application. and other problems, to achieve the effect of low production cost, good mechanical properties and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

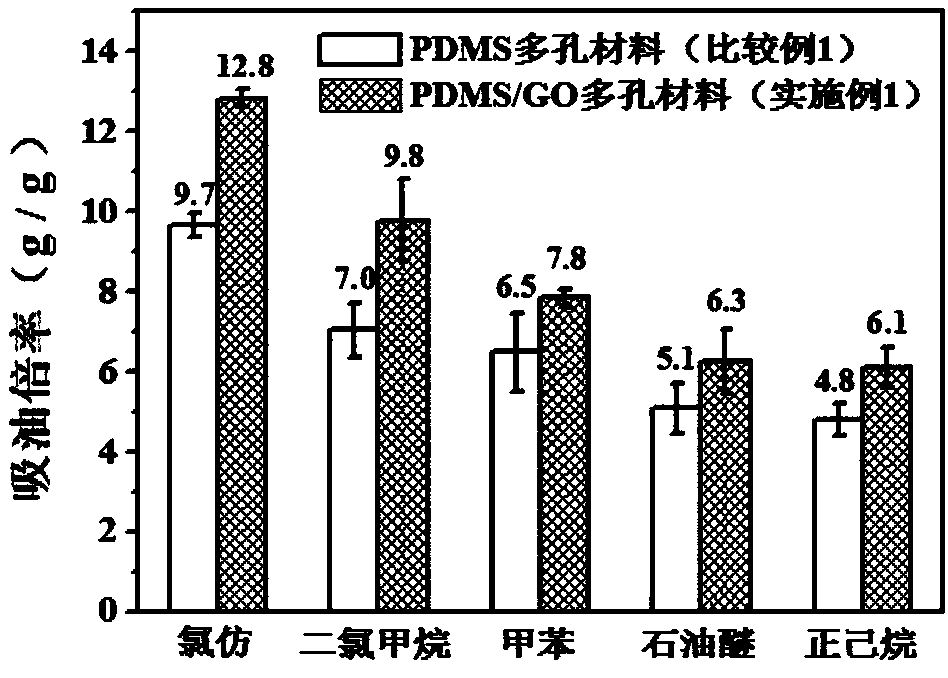

[0043] Embodiment 1, comparative example 1

[0044] 1. Sample preparation

[0045] (1) The preparation of embodiment 1 sample is carried out as follows:

[0046] Step 1: Mix 5.0g of polydimethylsiloxane (PDMS) prepolymer Sylgard 184A, 0.5g of cross-linking agent Sylgard184B and 6.0g of cyclohexane with ultrasonic (power 250W) and stir for 15min, then add 40.0g of sucrose (20.0g of raw sucrose with a particle size of 900-1800μm, 20.0g of white soft sugar with a particle size of 50-500μm), stir evenly, pour into a polytetrafluoroethylene mold and flatten it, and solidify at a temperature of 60°C 8h. After the reaction, the obtained PDMS-sucrose solid mixture was removed from the mold and placed in water at 80°C to dissolve the sucrose, washed with deionized water and absolute ethanol in sequence, and dried to obtain 5.02 g of PDMS porous material;

[0047] Step 2: Put 5.02 g of the PDMS porous material obtained in Step 1 in a 5M sodium hydroxide solution, and stir the reactio...

Embodiment 2

[0064] Embodiment 2, comparative example 2

[0065] 1. Sample preparation

[0066] (1) The preparation of embodiment 2 sample is carried out as follows:

[0067] Step 1-3: For the synthesis steps and process of the aminated PDMS porous material, refer to steps 1, 2 and 3 in Example 1;

[0068]Step 4: Immerse 4.00 g of the aminated PDMS porous material into a DMF dispersion (90 mL) of graphene oxide (GO) with a concentration of 2 mg / mL and a sheet diameter of 0.2 to 10 μm, and then slowly (20 min) drop A DMF solution (10 mL) of N,N'-dicyclohexylcarbodiimide (4.0 g) and 4-dimethylaminopyridine (0.3 g) was added, then the temperature was raised to 60° C. and the reaction was stirred for 20 h. After the reaction, the product was washed twice with DMF and once with absolute ethanol, and then vacuum-dried at 40°C for 1 day to obtain 4.02 g of PDMS / GO porous composite material.

[0069] (2) The preparation of comparative example 2 sample is carried out as follows:

[0070] Step 1...

Embodiment 3

[0079] Embodiment 3, comparative example 3

[0080] 1. Sample preparation

[0081] (1) The preparation of embodiment 3 sample is carried out as follows:

[0082] Step 1-3: For the synthesis steps and process of the aminated PDMS porous material, refer to steps 1, 2 and 3 in Example 1;

[0083] Step 4: immerse 2.52g of the aminated PDMS porous material into a DMF dispersion (90mL) of graphene oxide (GO) with a concentration of 1mg / mL and a sheet diameter of 0.2 to 10 μm, and then slowly (20min) ) was added dropwise with a DMF solution (10 mL) of N,N'-dicyclohexylcarbodiimide (4.0 g) and 4-dimethylaminopyridine (0.6 g), then heated to 70° C. and stirred for 20 h. After the reaction, the product was washed twice with DMF and once with absolute ethanol, and then dried in vacuum at 40°C for 1 day to obtain 2.54 g of PDMS / GO porous composite material.

[0084] (2) The preparation of comparative example 3 sample is carried out as follows:

[0085] Step 1-3: For the synthesis step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com