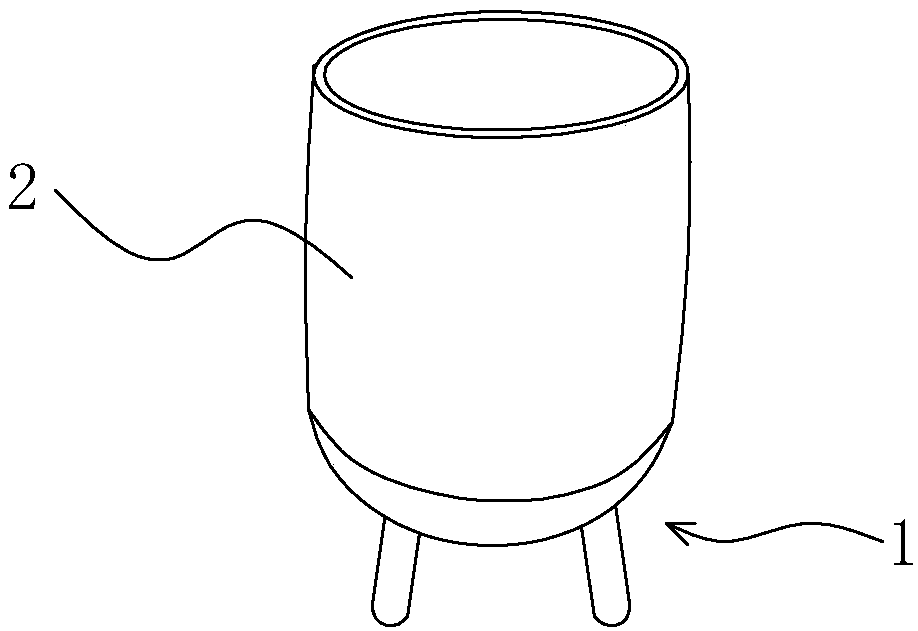

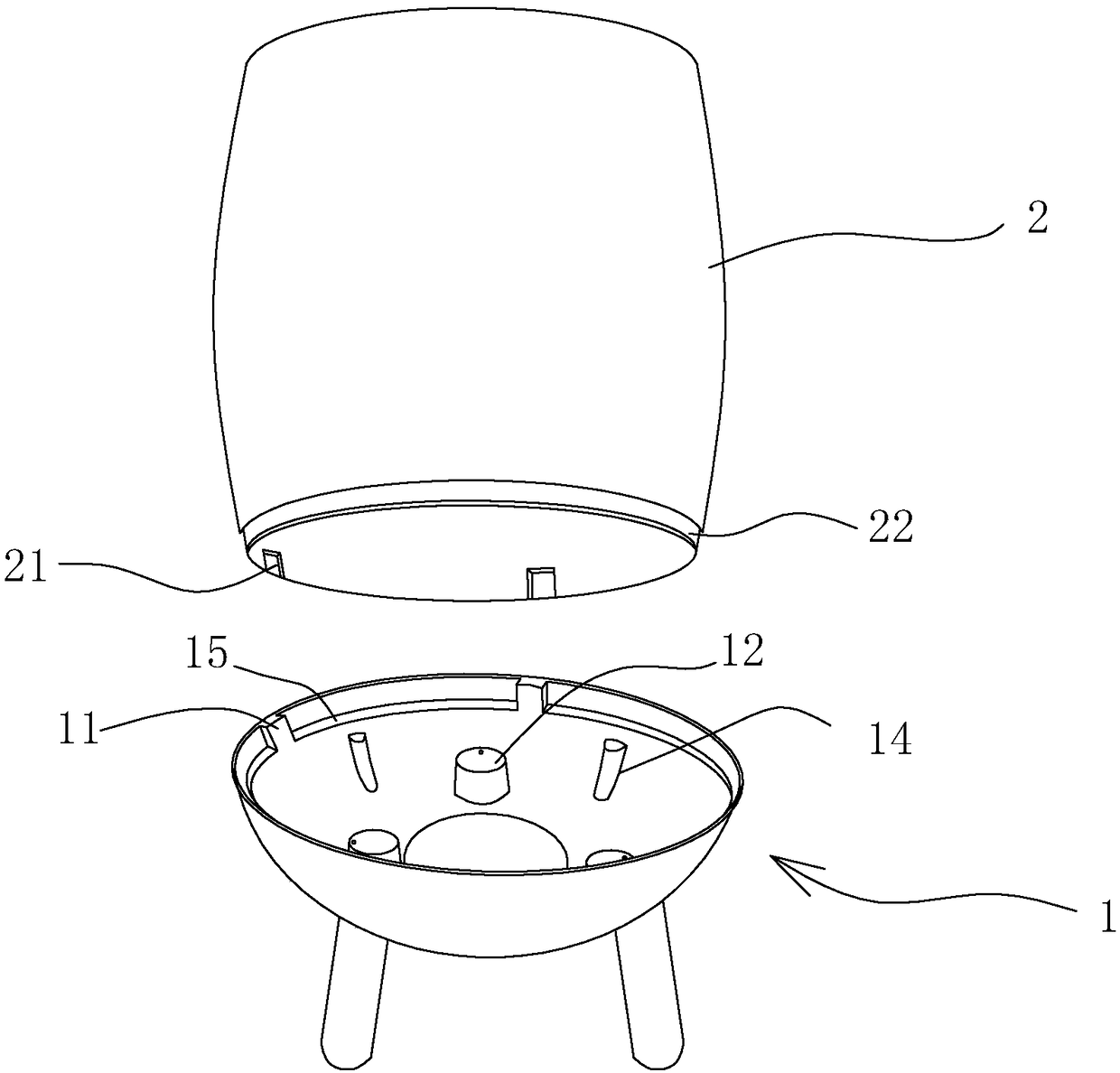

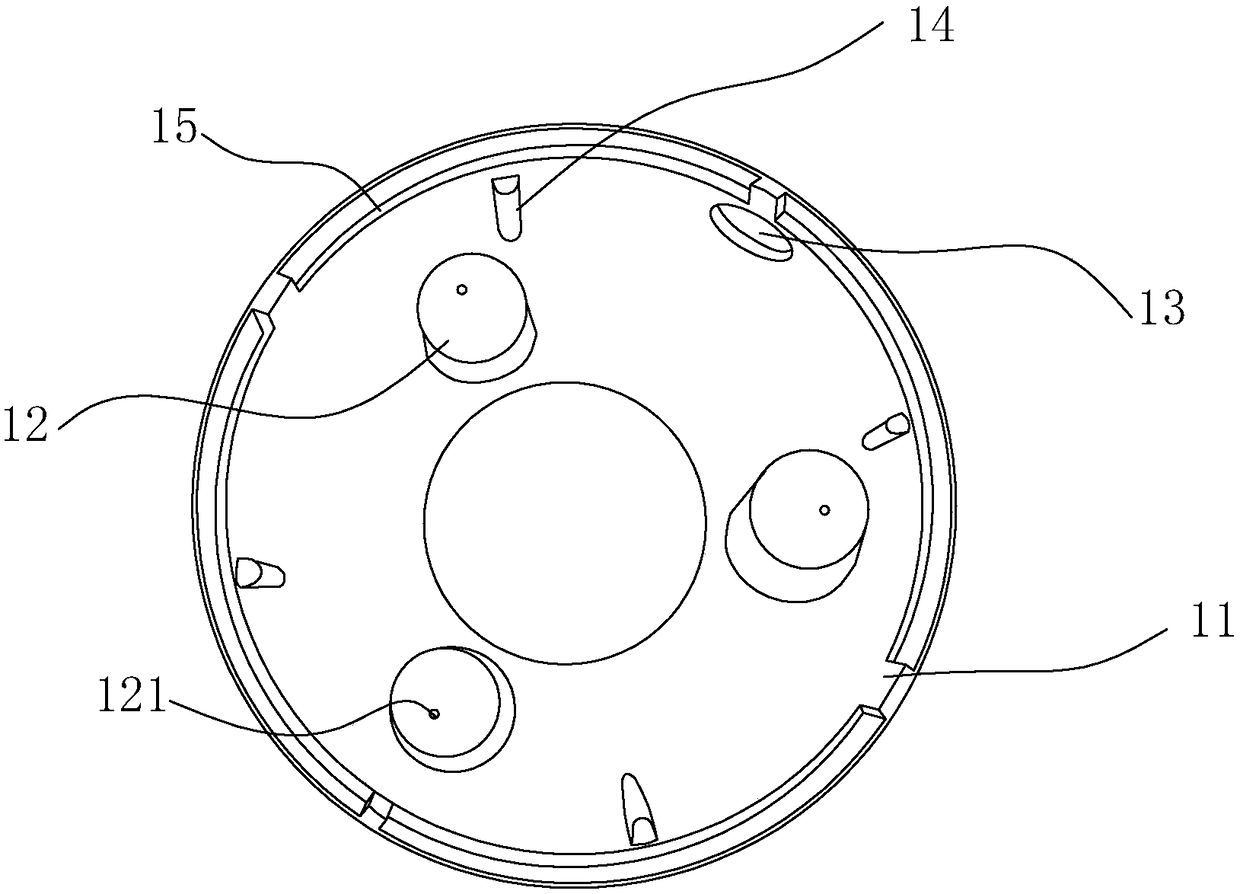

Degradable flowerpot produced by waste husk

A flowerpot and chaff technology, applied in application, cultivation, agriculture, etc., can solve the problems of single product and lack of waste production methods, achieve simple installation and disassembly, increase ventilation and moisture drainage performance, and prevent water accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A degradable flowerpot made of waste chaff, the material for making the flowerpot includes the following components in parts by mass: 30 parts of chaff; 30 parts of corn flour; 30 parts of urea-formaldehyde resin; 8 parts of quartz sand; 4 doses. In this embodiment, the adhesive is ethylene oxide. The chaff may or may not be crushed.

Embodiment 2

[0041] A degradable flowerpot made of waste rice husks. The material for making the flowerpot includes the following components in parts by mass: 50 parts of rice husks; 20 parts of corn flour; 20 parts of urea-formaldehyde resin; 12 parts of quartz sand; 6 doses. In this embodiment, the adhesive is dibutyl phthalate.

Embodiment 3

[0043] A degradable flowerpot made of waste rice husks. The material for making the flowerpot includes the following components in parts by mass: 40 parts of rice husks; 25 parts of corn flour; 25 parts of urea-formaldehyde resin; 10 parts of quartz sand; 5 doses. In this embodiment, the adhesive is dioctyl phthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com