A kind of reversible thermochromic printing ink and its preparation method and application

A printing ink and thermochromic technology, which is applied in the field of inkjet printing, can solve the problems of color-changing inks that have not yet been found, and achieve the effects of stable printing performance, prevention of uneven dispersion, and uniform dispersion of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the thermochromic printing ink provided in this embodiment comprises the following steps:

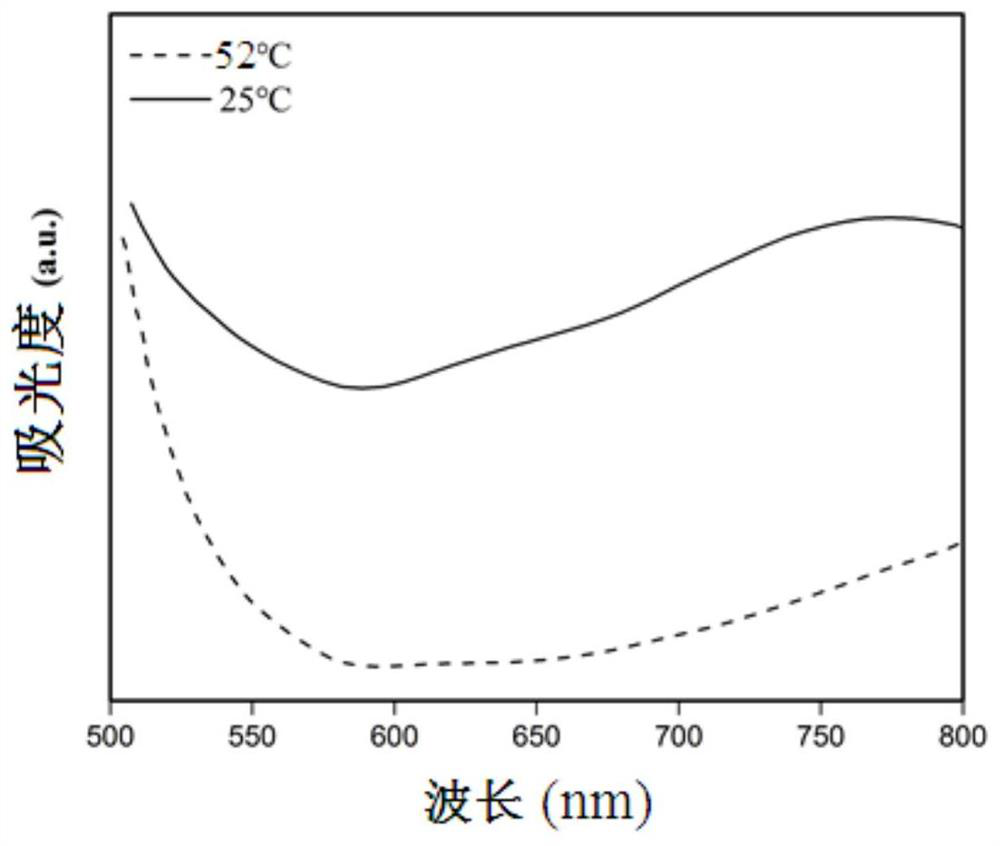

[0041] (1) thermochromic material [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 preparation of

[0042] CuCl 2 2H 2 O 17g and (C 2 h 5 ) 2 Dissolve 21.2g of NH·HCl in 140g of deionized water, stir and mix evenly, react in a constant temperature water bath at 70°C for 2 hours, take it out and cool to room temperature, after the solid precipitates, filter it with absolute ethanol, collect the solid, and weigh it with absolute ethanol Crystallize twice, put the crystals into a vacuum drying oven, and dry them at 60°C for 3 hours to obtain 38 g of bright green needle-like crystals, namely [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 .

[0043] After testing, [(C 2 h 5 ) 2 NH 2 ] 2 CuCl4 The purity is 99.99%, the grain size is 18-31μm, and the relative humidity is 15%.

[0044] (2) Preparation of printing ink

[0045] Slowly add 25.5 g of acrylic resin emulsion (its...

Embodiment 2

[0051] The preparation method of the thermochromic printing ink provided in this embodiment comprises the following steps:

[0052] (1) thermochromic material [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 preparation of

[0053] CuCl 2 2H 2 O 17g and (C 2 h 5 ) 2 Dissolve 19.7g of NH·HCl in 120g of deionized water, stir and mix evenly, react in a constant temperature water bath at 60°C for 2 hours, take it out and cool to room temperature, after the solid precipitates, filter it with absolute ethanol, collect the solid, and weigh it with absolute ethanol Crystallize twice, put the crystals in a vacuum drying oven, and dry them at 60°C for 3 hours to obtain 34.1 g of bright green needle-like crystals, namely [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 .

[0054] After testing, [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 The purity is 99.9%, the grain size is 10-39μm, and the relative humidity is 12%.

[0055] (2) Preparation of printing ink

[0056] Slowly add 25 g of water-based acrylic resin so...

Embodiment 3

[0059] The preparation method of the thermochromic printing ink provided in this embodiment comprises the following steps:

[0060] (1) thermochromic material [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 preparation of

[0061] CuCl 2 2H 2 O 17g and (C 2 h 5 ) 2 Dissolve 16.4g of NH·HCl in 120g of deionized water, stir and mix evenly, react in a constant temperature water bath at 65°C for 2h, take it out and cool to room temperature, after the solid precipitates, filter it with absolute ethanol, collect the solid, and weigh it with absolute ethanol Crystallize twice, put the crystals in a vacuum drying oven, and dry them at 60°C for 3 hours to obtain 29 g of bright green needle-like crystals, namely [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 .

[0062] After testing, [(C 2 h 5 ) 2 NH 2 ] 2 CuCl 4 The purity is 99.99%, the grain size is 16-42μm, and the relative humidity is 20%.

[0063] (2) Preparation of printing ink

[0064] Slowly add 17.5 g of polyvinyl alcohol to 22.5 g of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com