Gas distributor and gasification furnace

A gas distributor and conical distribution technology, which is used in the manufacture of combustible gas, feeding tools for gasification devices, and granular/powder fuel gasification, etc., can solve the problems of difficult maintenance, wear of jet tubes, and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

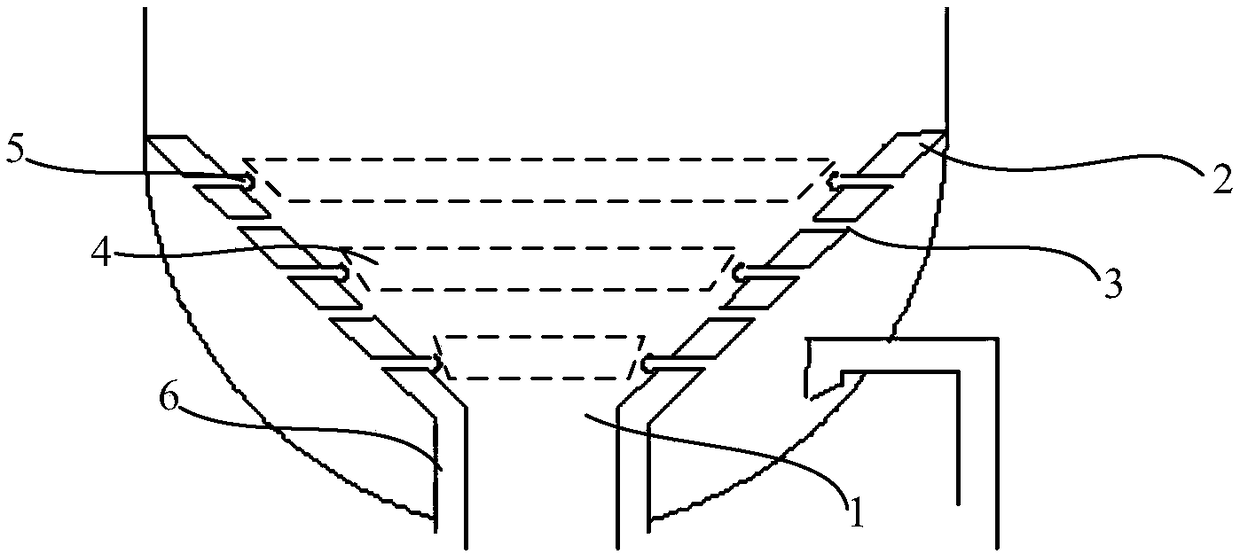

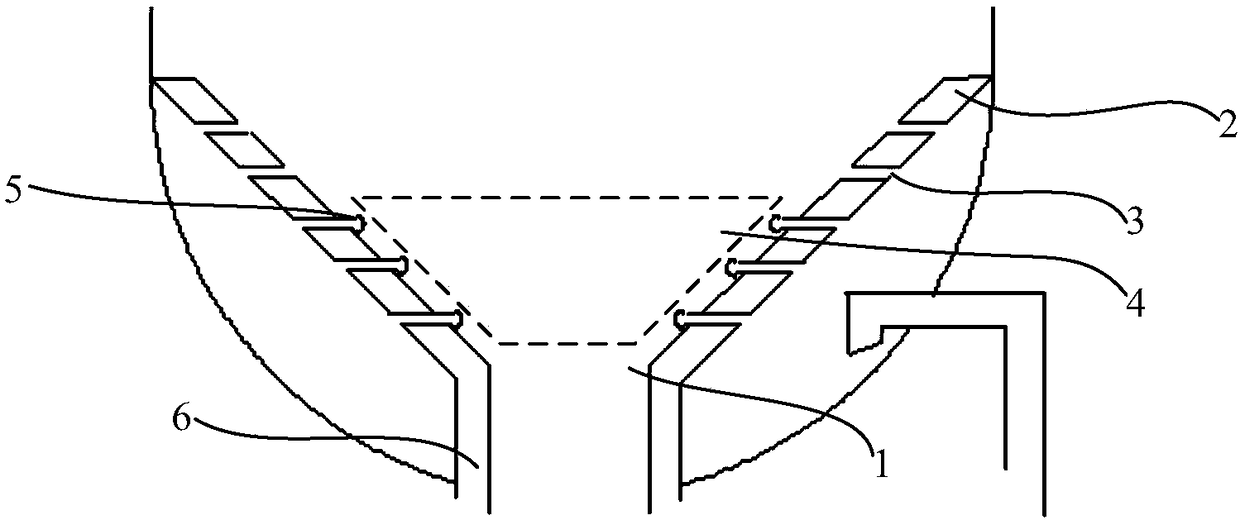

[0052] The high-temperature gasification process uses long-flame coal as the gasification raw material. The design of the gasifier adopts a centerless jet structure. During the gasification process, the coal particle size distribution is uniform (basically stable within the particle size range of 1mm-2mm), and the gas Distributors are used as figure 1 The structure shown, that is, the horizontal opening 3 on the conical distribution plate 2 adopts the horizontal opening 3 not connected to the air distribution structure 5 and the horizontal opening 3 connected to the air distribution structure 5 along the axial direction of the conical distribution plate 2. The holes 3 are arranged alternately. The air distribution structure 5 is an air distribution pipe 51 extending along the horizontal direction. Side connection, the second end is connected with a blocking member 53, the blocking member 53 includes a cylindrical connecting portion connected to the circumference of the second ...

Embodiment 2

[0054] The granular organic carbon material is used as the raw material for gasification. The design of the gasifier adopts a centerless jet structure, and the particle size distribution of the material is uniform during the gasification process (basically stable within the particle size range of 1mm-2mm). The gas distributor adopts Such as figure 1 The structure shown, that is, the horizontal opening 3 on the conical distribution plate 2 adopts the horizontal opening 3 not connected to the air distribution structure 5 along the axial direction of the conical distribution plate 2 and the horizontal opening 3 connected to the air distribution structure 5 3 alternately arranged, the air distribution structure 5 is an air distribution pipe 51 extending along the horizontal direction, the first end of the air distribution pipe 51 and the horizontal opening 3 are located on the inner ring surface side of the conical distribution plate 2 connection, the second end is connected with ...

Embodiment 3

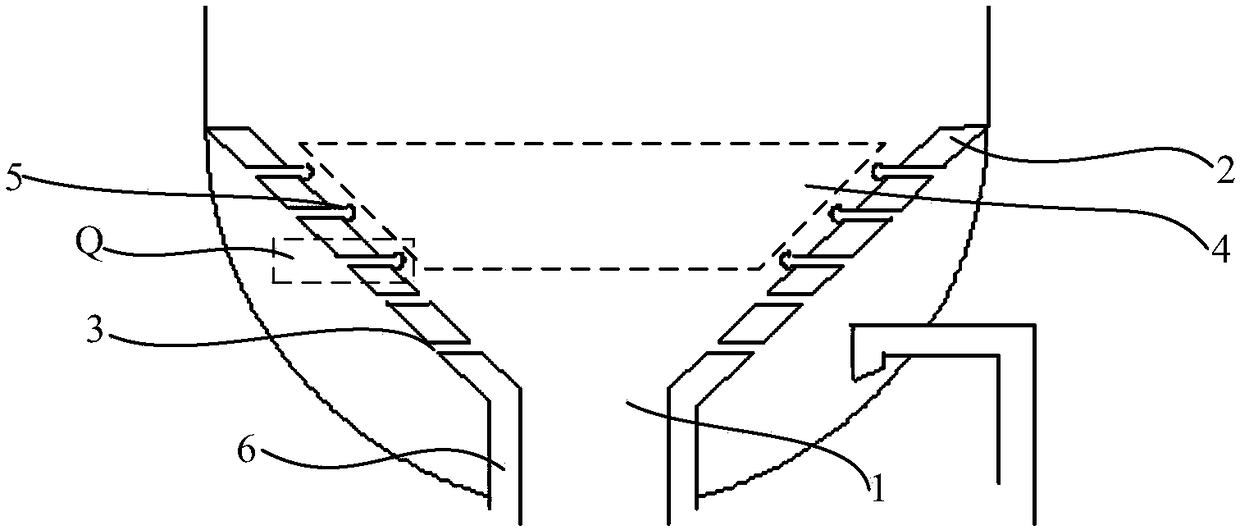

[0056] A kind of crushed garbage is used as the gasification raw material, and the design of the gasifier adopts a centerless jet structure. Since the particle size distribution of gasification raw materials is wide and there are more large particles, the gas distributor adopts image 3 The structure shown is similar to that of Embodiment 1. The air distribution structure 5 includes an air distribution pipe 51. The second end of the air distribution pipe 51 is closed by a blocking member 53. The outer surface of the recess on the blocking member 53 is Columnar structure, and the aperture of the horizontal opening 3 is 0.6 times the inner diameter of the cylindrical connection part on the blocking member 53, and the air distribution pipe 51 is provided with three air distribution holes 52 along the axial direction near the second end. The gas velocity of 52 is 0.9 times of the gas velocity of the horizontal opening 3. During the experimental operation, the slag discharge is sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com