An automatic ash conveying device for a gas furnace dust collector

A technology for dust collectors and gas stoves, used in the manufacture of combustible gas, petroleum industry, etc., can solve problems such as fire or explosion, accidents, blockage of pipelines, etc., and achieve the effect of liberating labor, prolonging service life, and transporting ash cleanly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

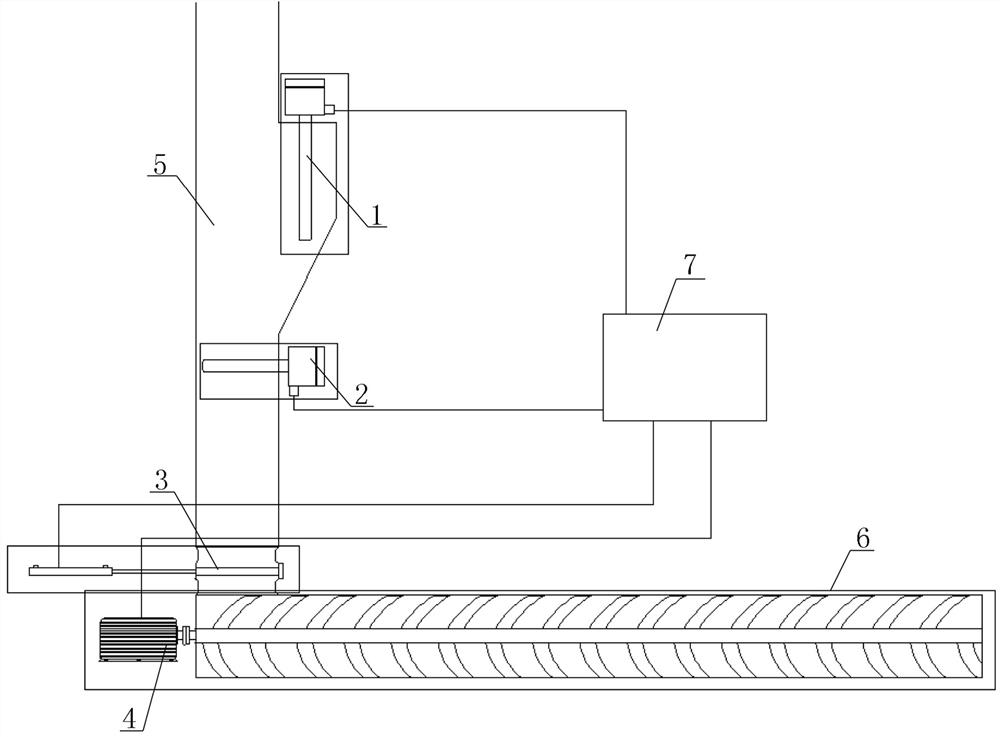

[0019] Such as figure 1 As shown, an automatic ash conveying device for a dust collector of a gas furnace includes an ash collecting hopper 5, which is arranged vertically, an on-off valve 3 is arranged in the ash discharge port at the bottom of the ash collecting hopper 5, and the bottom of the ash collecting hopper 5 The end is connected with the ash conveyor 6, a thermometer 2 is provided in the middle and lower section of the ash collection hopper 5, and a level gauge 1 is provided in the middle and upper section of the ash collection hopper 5.

[0020] The thermometer 2 is an electronic thermometer 2, the level gauge 1 is an electronic level gauge 1, and the ash conveyor 6 includes a screw conveyor and a driving motor 4 connected to the driving end of the screw conveyor.

[0021] A controller 7 is included, the input end of the controller 7 is connected with the electronic level gauge 1 , and the output end of the controller 7 is connected with the controlled end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com