Rotary fermentation tank for fermented soybeans and fermented soybean manufacturing process

A production process and fermenter technology, which is applied in the field of fermented soy bean fermentation tank and fermented soy bean production process, can solve the problems of damage to bean skin and damage to the integrity of raw bean, achieve the goal of reducing stirring intensity, avoiding damage to bean skin, and increasing filling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

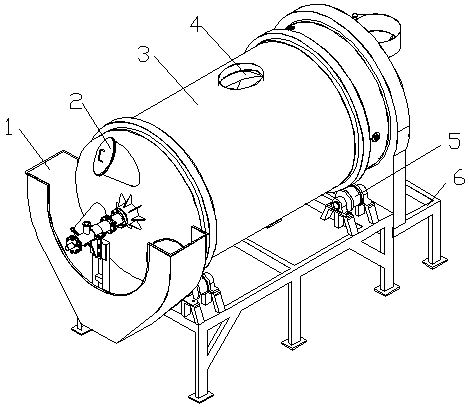

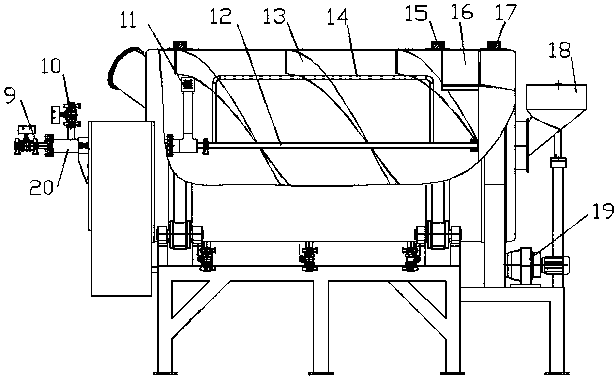

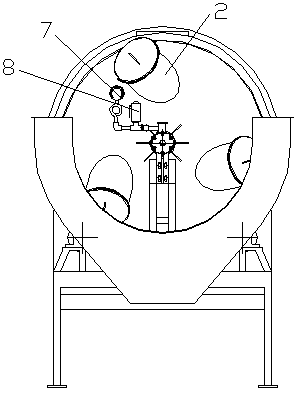

[0031] like Figure 1~4 A fermented soy bean rotary fermenter is shown, comprising a bottom frame 6 and a horizontal tank body 3 driven to rotate by a driving device. The front and rear ends of the tank body 3 are respectively provided with a discharge port 2 and a feed port. One end of the feed port is provided with a feed funnel 18, and the inner wall of the tank is fixed with helical blades extending axially. In order to improve the effect of pushing materials and stirring and mixing, the helical blades in this embodiment are double helical blades 13, and there are also helical blades in the tank. An oxygen exhaust device is provided, and an inspection port 4 is provided on the tank body for easy maintenance.

[0032] The driving device includes a roller 5 supporting the tank body 3, and a driving gear 21 connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com