Oily sludge horizontal stirring, tempering and cleaning device

A cleaning device, mud horizontal technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of inconvenient oil slick collection and damage to the bearing of the horizontal agitator Dynamic sealing, oil leakage and other problems, to achieve complete mixing and continuous feeding, enhance the effect of stirring, conditioning and cleaning, and ensure the effect of conditioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For a clearer understanding of the purpose, technical solutions and technical effects of the present invention, the present invention is further described below, but the protection scope of the present invention is not limited to the following examples.

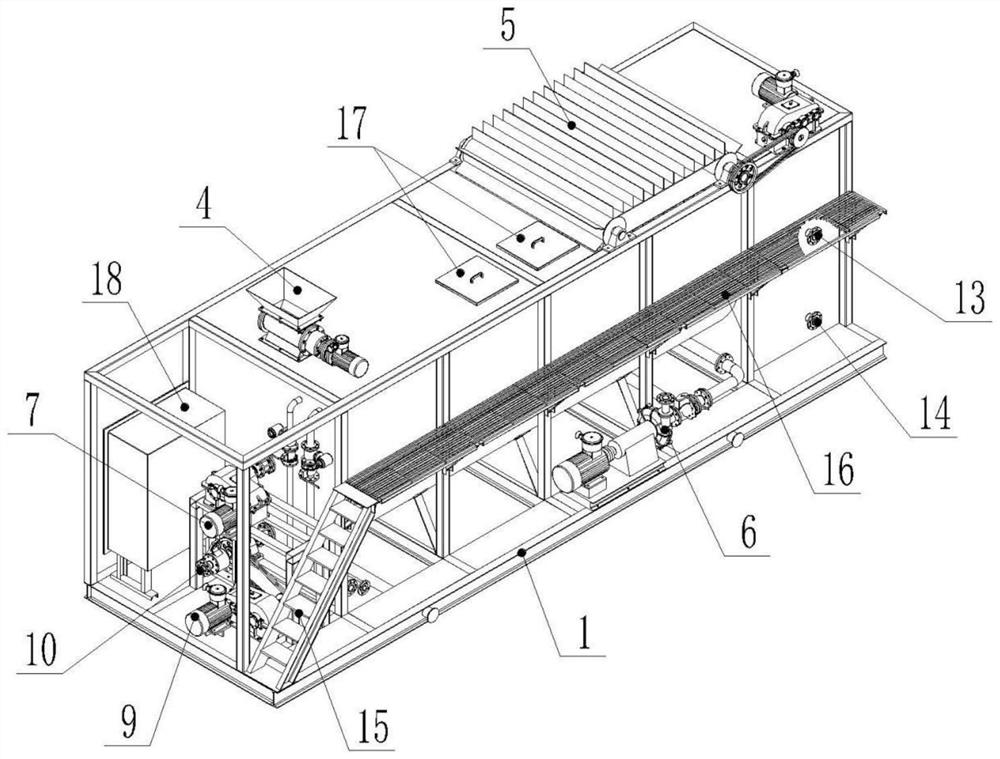

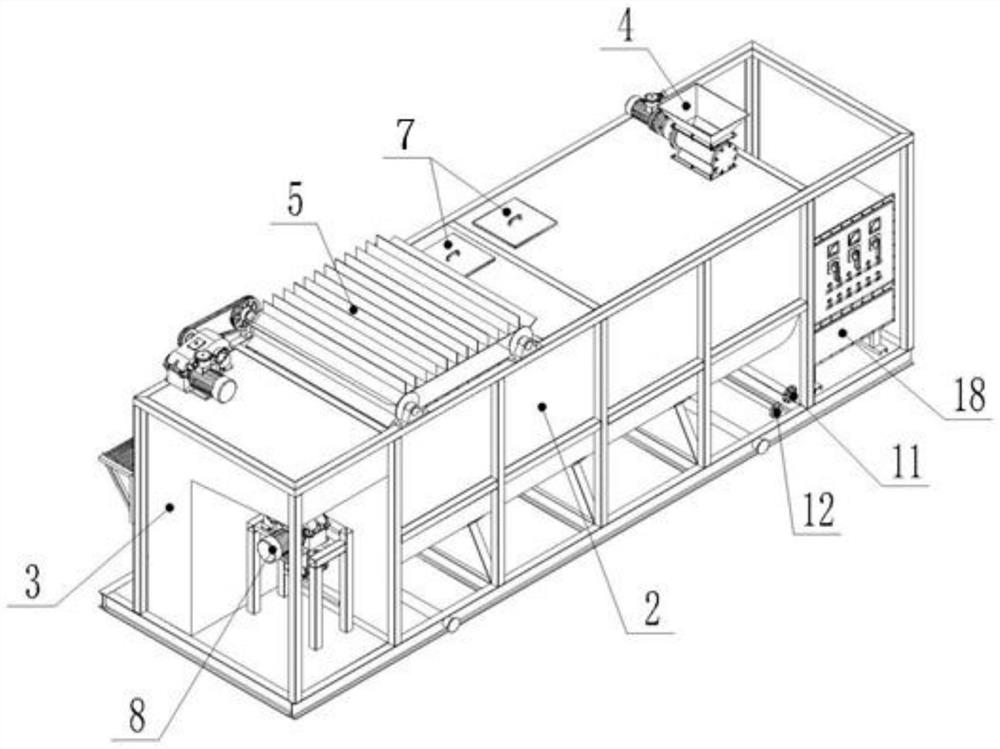

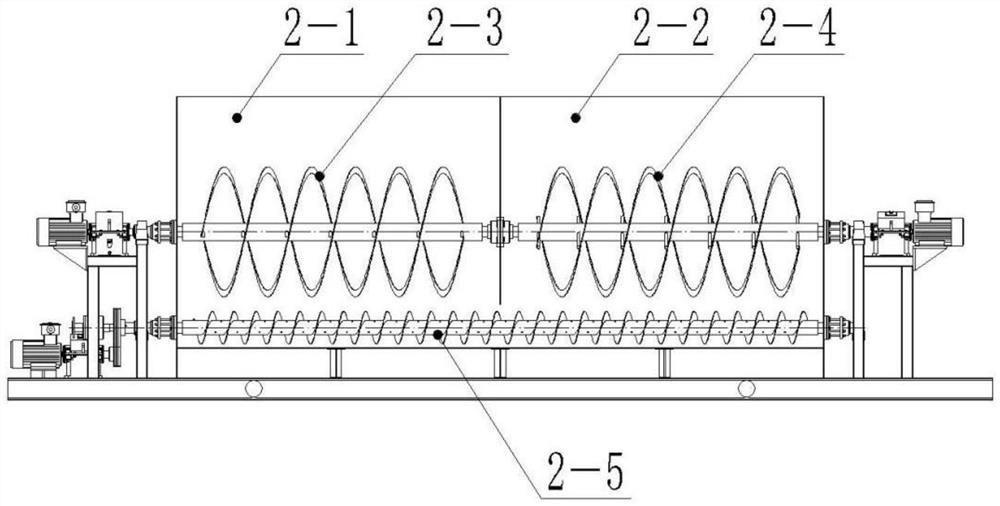

[0024] like Figure 1-3 As shown, a horizontal stirring, conditioning and cleaning device for oily sludge includes: a skid seat (1), a ribbon stirrer (2-3, 2-4), a screw propeller (2-5) and a horizontal stirring tank (2); the horizontal stirring tank (2) includes two different stirring regions, a stirring region A (2-1) and a stirring region B (2-2), and the bottoms of the two different stirring regions are connected; The ribbon stirrer includes a ribbon stirrer a (2-3) and a ribbon stirrer b (2-4), and the ribbon stirrer a (2-3) is arranged in the stirring zone A (2-4). In -1), the ribbon stirrer b (2-4) is arranged in the stirring zone B (2-2); the screw propeller (2-5) is arranged in the horizontal stirring tank ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com