Connecting component of assembly type frame infilled wall and connecting method thereof

A technology for connecting components and filling walls, which is applied to building components, walls, building structures, etc., can solve the problems of infilling walls that cannot be disassembled and reused, poor controllability of construction quality, and increased construction costs, so as to improve the reuse rate, Avoid wet work, strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

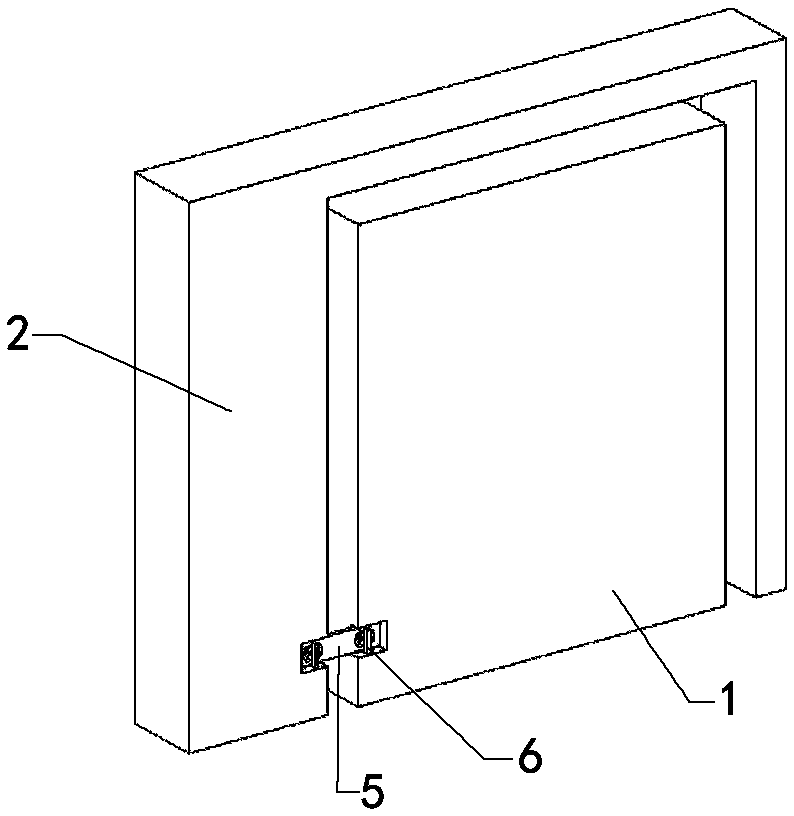

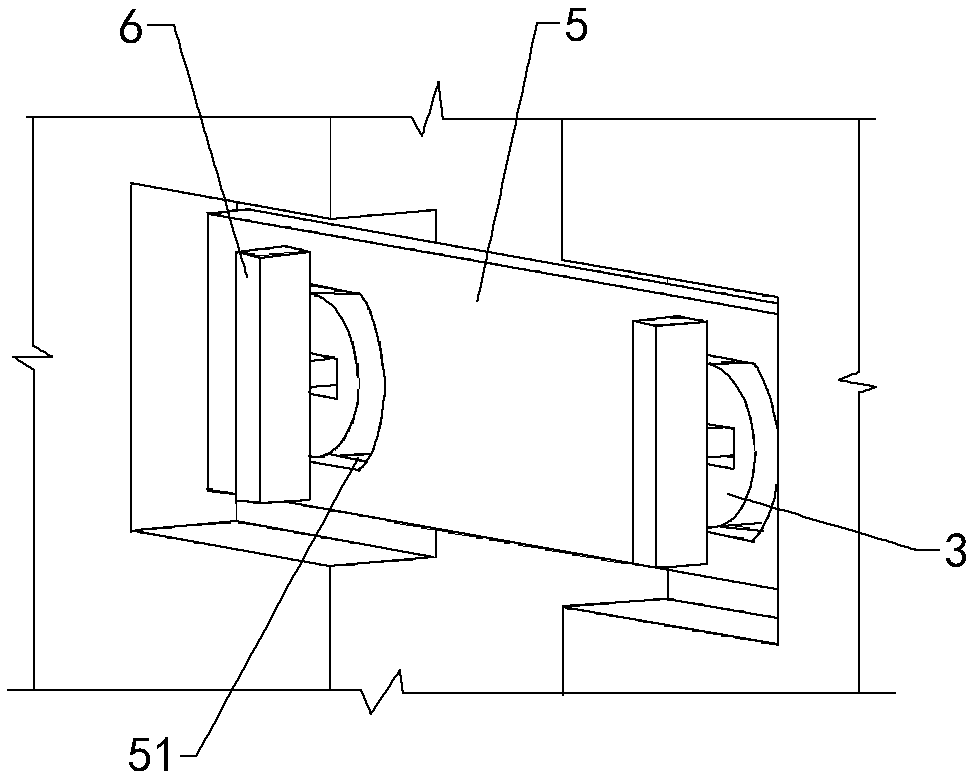

[0035] Such as Figure 1 to Figure 3 As shown, the connecting member of the assembled frame filling wall of the present invention is used to connect the filling wall 1 and the frame column 2, including embedded parts, connecting plates 5 and I-shaped connecting rods 6 .

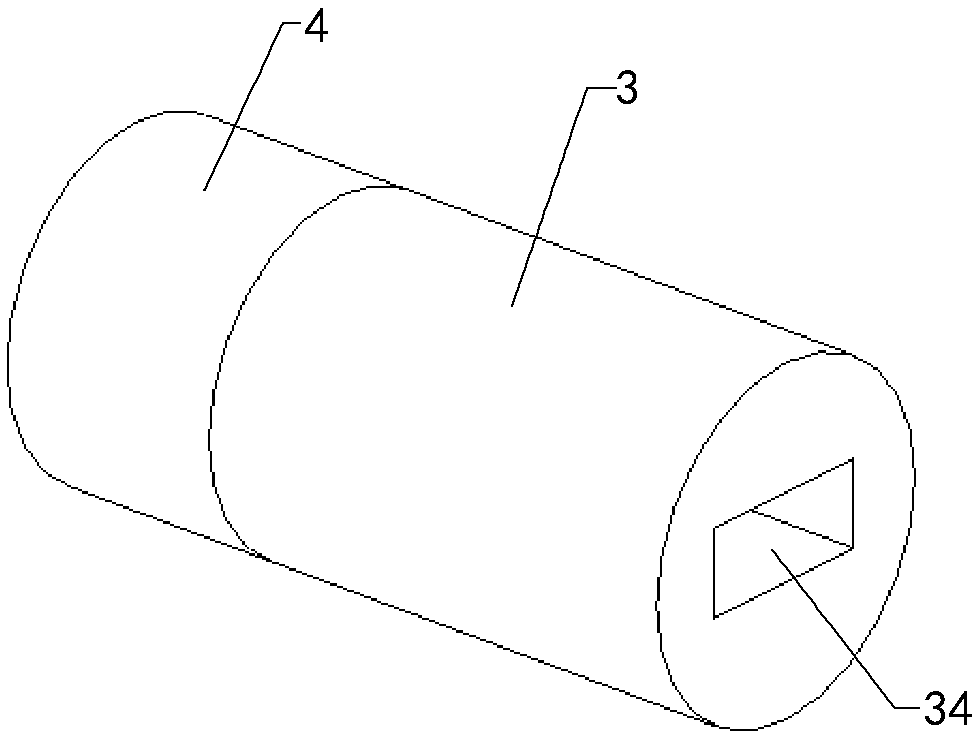

[0036] The embedded parts are cylindrical steel parts, which are arranged symmetrically on the filling wall 1 and the frame column 2 respectively, including the first member 3 and the second member 4 connected in sequence by threads;

[0037] Such as Figure 4 As shown, the first component 3 includes a pre-embedded main body 31, and a first connecting portion 33 arranged on one end surface of the pre-embedded main body 31; A rectangular through hole 34 is provided, the cross-sectional length of the rectangular through hole 34 is not less than 4 / 5 of the diameter of the embedded main body 31, and the end face on the other side of the embedded main body 31 protrudes from the surface of the filling wall 1 or fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com