Manual compression tool for lap joint of color tiles and its operation method

A color plate and tool technology, which is applied in the field of manual pressing tools for color plate tile overlap, can solve the problems of high price, water seepage, and easy damage to the tile surface, and achieves the effects of high construction precision, labor-saving operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

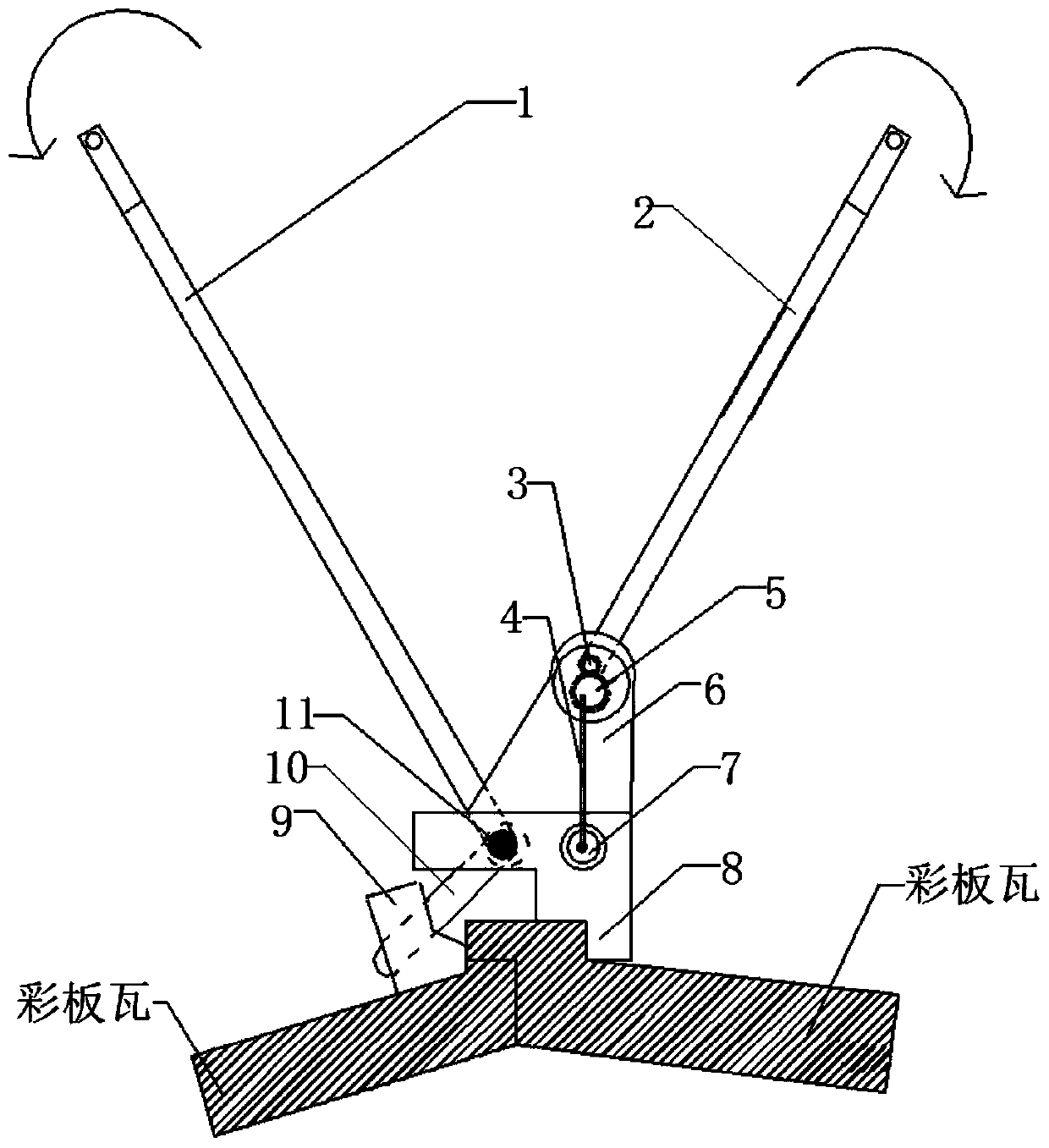

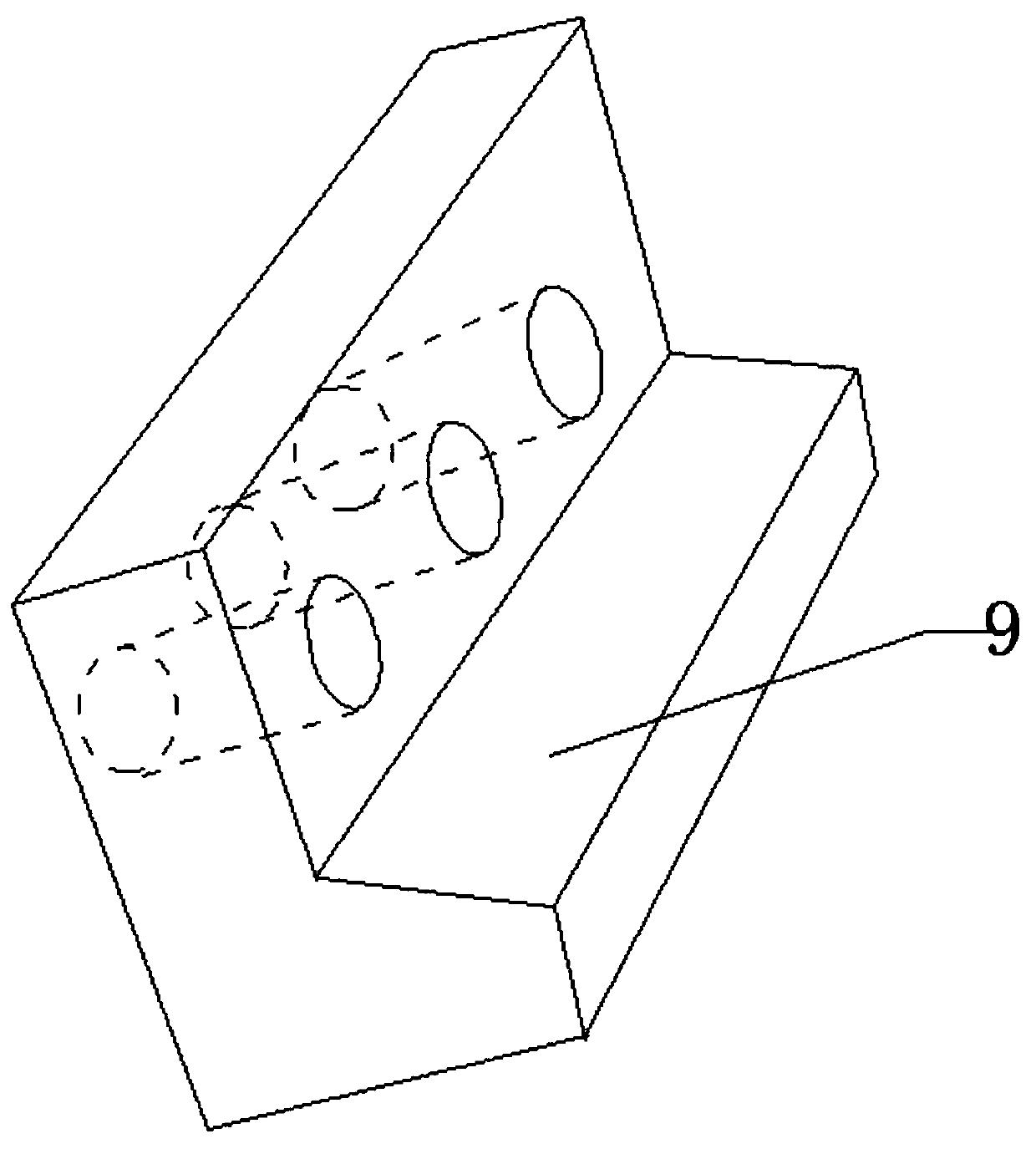

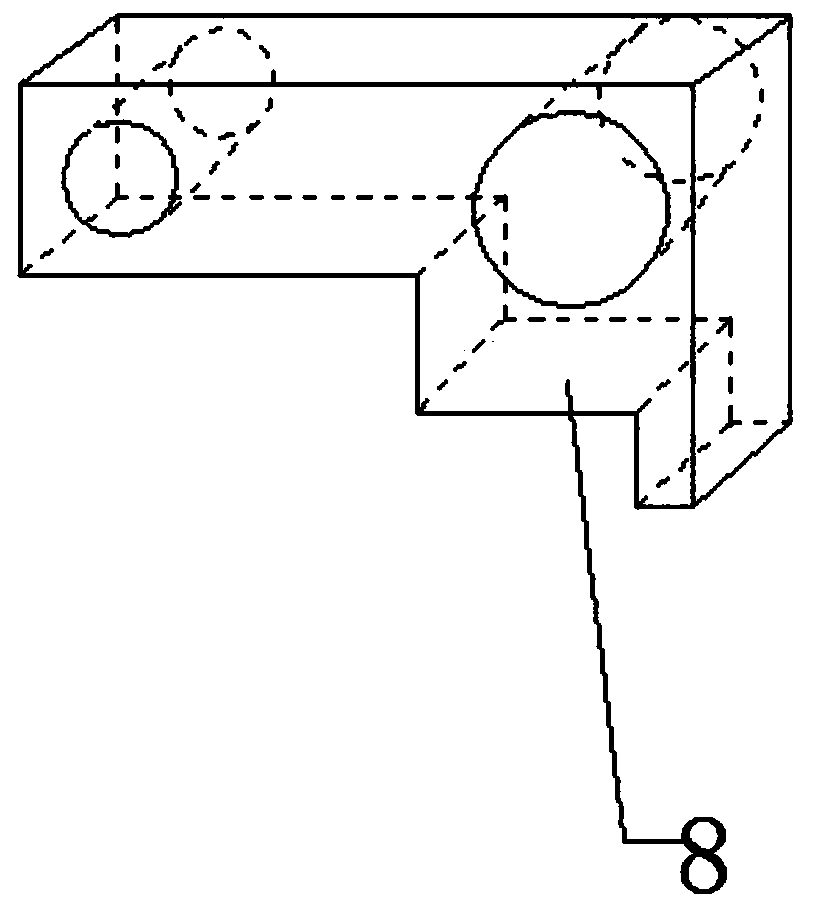

[0020] Such as Figure 1 to Figure 5 As shown in the figure, a hand-pressing tool for lap joints of color tiles includes a support 6, an undercut block 8 and a limit block 9, the lower part of the support 6 and the upper part of the undercut block 8 are hinged by a rotating shaft 11, and the upper and lower sides of the rotating shaft 11 are respectively fixed. Limiting handle 1 and connecting rod 10, the limiting block 9 is adjustable on the connecting rod 10, the upper part of the undercut block 8 is provided with the pressing shaft 7, the lower part is the undercutting tooth, and the upper part of the support 6 is provided with a rotatable transmission shaft 3 and the gear set 5 that can increase the torque, the undercut handle 2 is fixed on the upper side of the transmission shaft 3, the input gear of the gear set 5 is coaxially connected with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com