Energy system optimization scheduling method based on multi-working-condition equipment operation

A technology for energy systems and working conditions, applied in the energy industry, general control systems, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In order to illustrate the technical solutions of the present invention, specific examples are used below to illustrate.

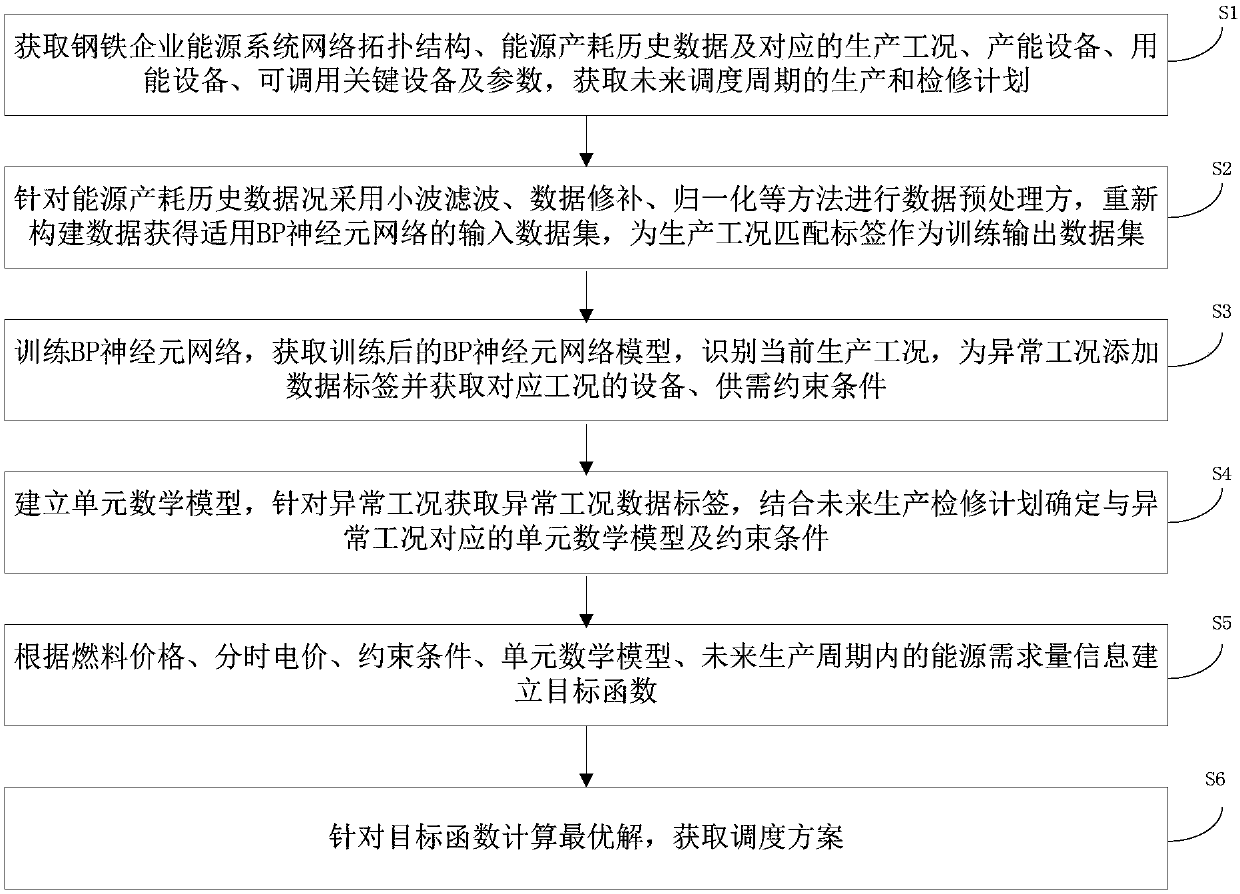

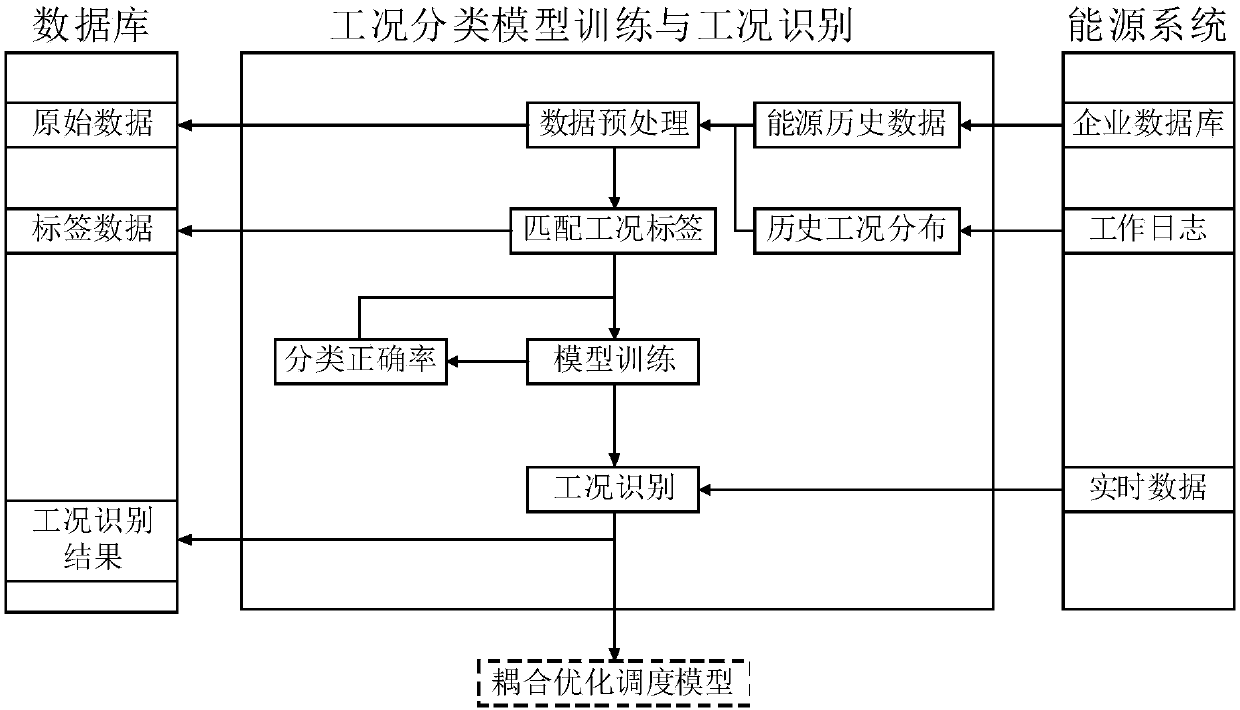

[0077] Such as figure 1 The flow chart of the iron and steel enterprise gas, steam, electric power system optimization scheduling method provided by the present invention, the method includes the following steps:

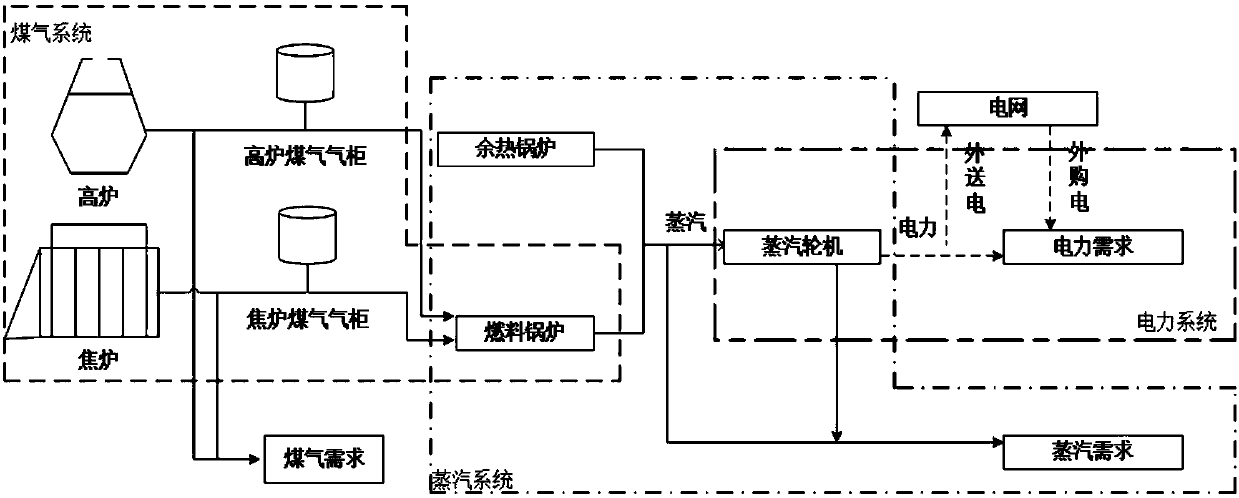

[0078] S1. Obtain the enterprise energy topological network structure, historical data of energy production and consumption of the gas steam power system and its corresponding production condition records; determine production capacity equipment, energy consumption equipment and dispatchable equipment; obtain key information and dispatch parameters of dispatchable equipment ; Obtain the production plan and maintenance plan within the scheduling cycle;

[0079] S11. Obtain the energy topological network structure of the enterprise, the historical data of energy production and consumption of the gas steam power system and its corresponding...

Embodiment 2

[0136] Such as Figure 4 Shown is the iron and steel enterprise gas, steam, electric power system optimization flowchart of the present invention, when performing optimization calculation, first use Python software programming to obtain the working condition identification and prediction information obtained in step S3, the supply and demand of energy media such as gas, steam and electric power Prediction results and unbalanced quantity prediction results; then program the objective function and constraint conditions in Python software; finally use Python software programming to call the solver CONOPT to solve, and obtain the energy medium distribution scheme with the lowest economic operation cost, and the corresponding scheduling The plan is displayed in the form of a chart, and the comparison and analysis of the results before and after optimization are performed, and the scheduling plan is saved to the database. The specific steps are as follows:

[0137] S61. Using Python...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com