Green recycling system and method for glass tube of waste and old fluorescent lamp

A recycling system and fluorescent lamp technology, applied in the field of green recycling system for waste fluorescent lamp glass tubes, can solve the problem of not taking into account the separation and recycling of glass at the same time, and achieve the effects of convenient operation and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

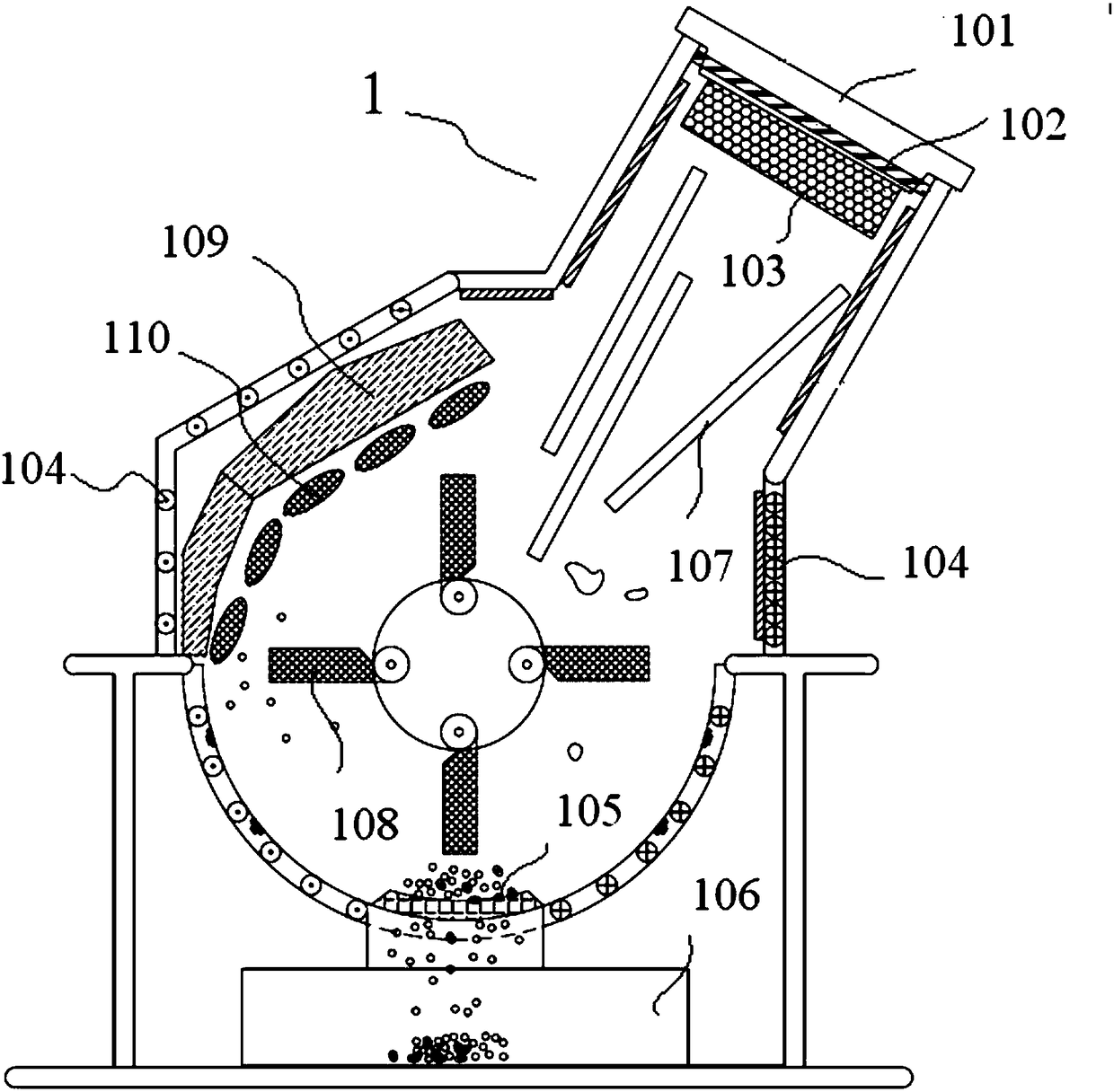

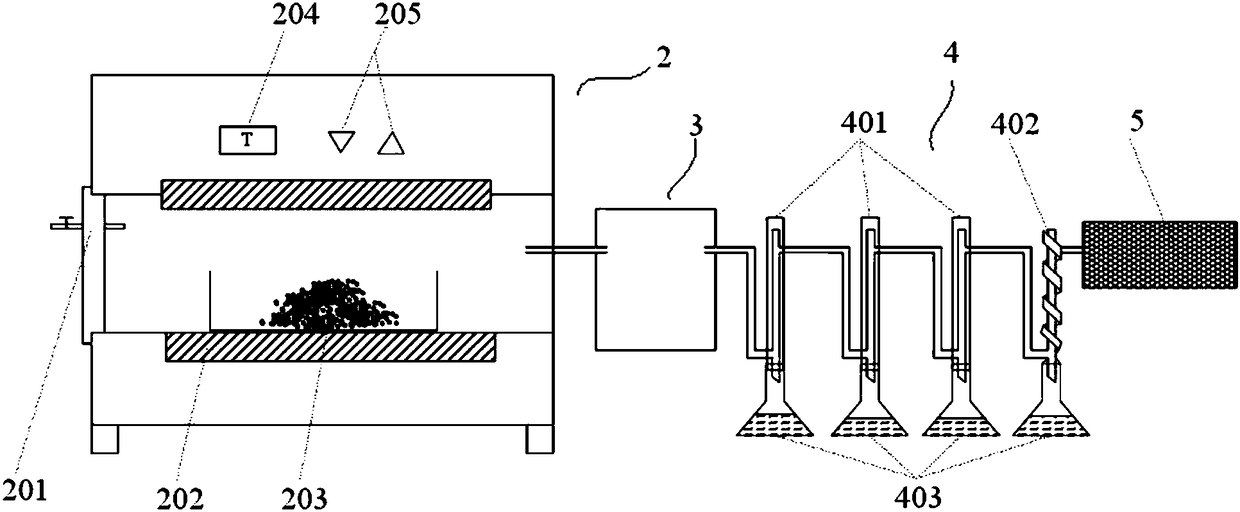

[0052] An embodiment of the green recycling system for waste fluorescent lamp glass tubes of the present invention, the green recycling system for waste fluorescent lamp glass tubes in this embodiment includes a glass crushing device, a vacuum heating device, a condensation device, a vibration grading and screening device, and an eddy current separation device and photoelectric separation device.

[0053] The glass crushing device described in this embodiment is as figure 1 As shown, the glass crushing device 1 is a shearing crusher, the glass crushing device 1 is provided with a material inlet cover 101, the material inlet cover is provided with a sealing rubber ring 102, and the inner side of the material inlet cover 101 is detachable Filling tank 103 is provided on the ground, and sulfur-loaded activated carbon is housed in the stuffing tank 103. The glass breaking device is provided with a condensate pipeline 104. The outer wall of the glass breaking device is provided wit...

Embodiment 2

[0063] A kind of embodiment of waste fluorescent lamp glass tube green recycling method of the present invention, as Figure 4 shown, including the following steps:

[0064] (1), breaking: breaking the waste fluorescent lamp glass tube to obtain a broken mixture;

[0065] (2) Mercury removal: heating the broken mixture under vacuum conditions, and then condensing the volatilized mercury vapor to obtain elemental mercury and the broken mixture after removing mercury;

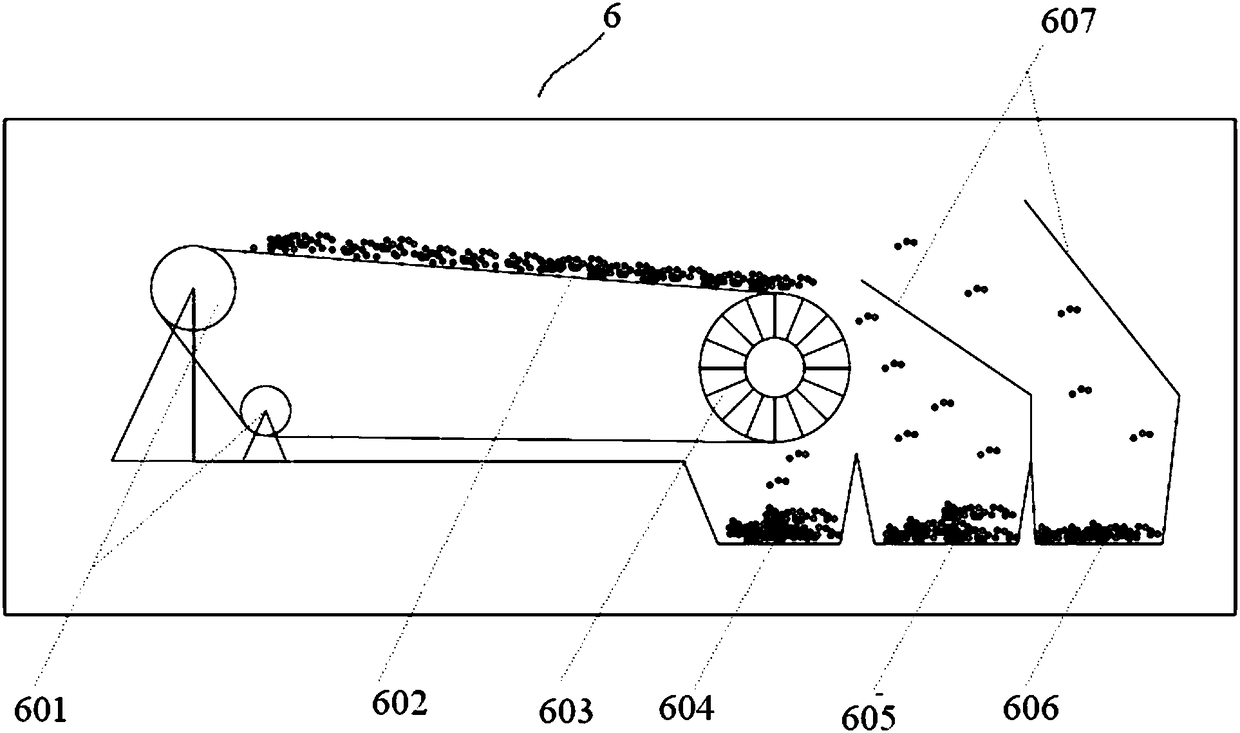

[0066] (3) Phosphor removal: the crushed mixture after mercury removal is vibrated, classified and sieved to obtain a crushed mixture of large particles and a powdery phosphor powder containing rare earth metals;

[0067] (4), eddy current separation: the crushed mixture of the large particles obtained in step (3) is subjected to eddy current separation to obtain magnetic metal particles, non-magnetic metal particles and clean glass fragments;

[0068] (5), photoelectric sorting: the clean glass shards obtained...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap