A temperature-sensitive composite electrode and its preparation method

A composite electrode, sensitive technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor surface dispersion of the active material core, loss of battery specific energy and rate performance, low conductivity of PTC materials, etc. Room temperature and rate performance, reliable PTC effect, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

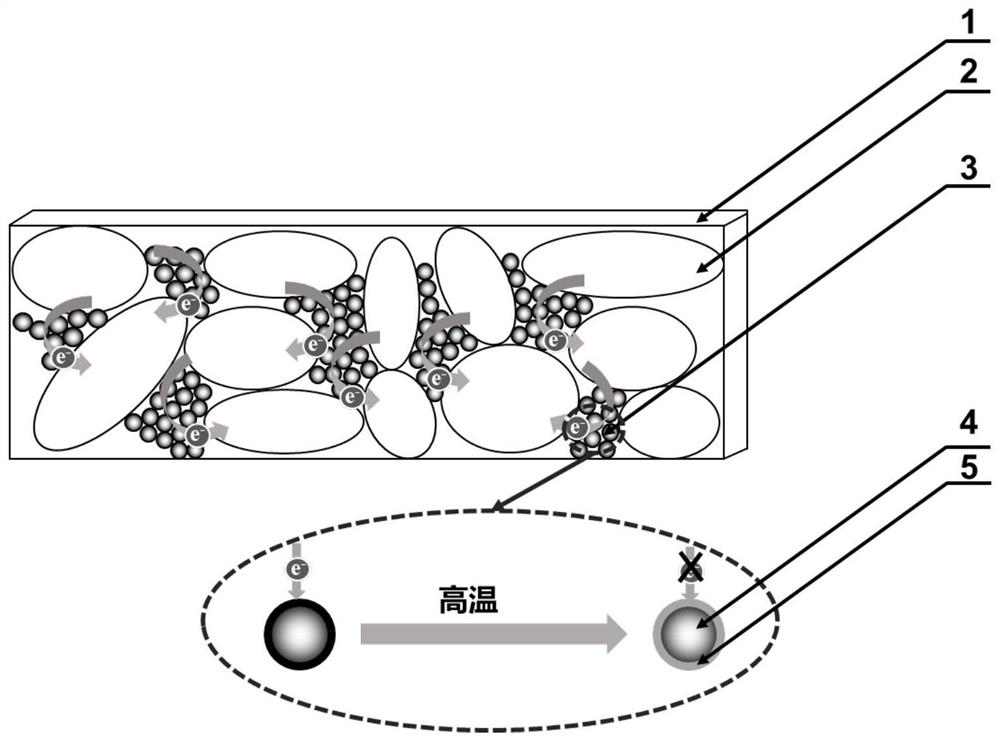

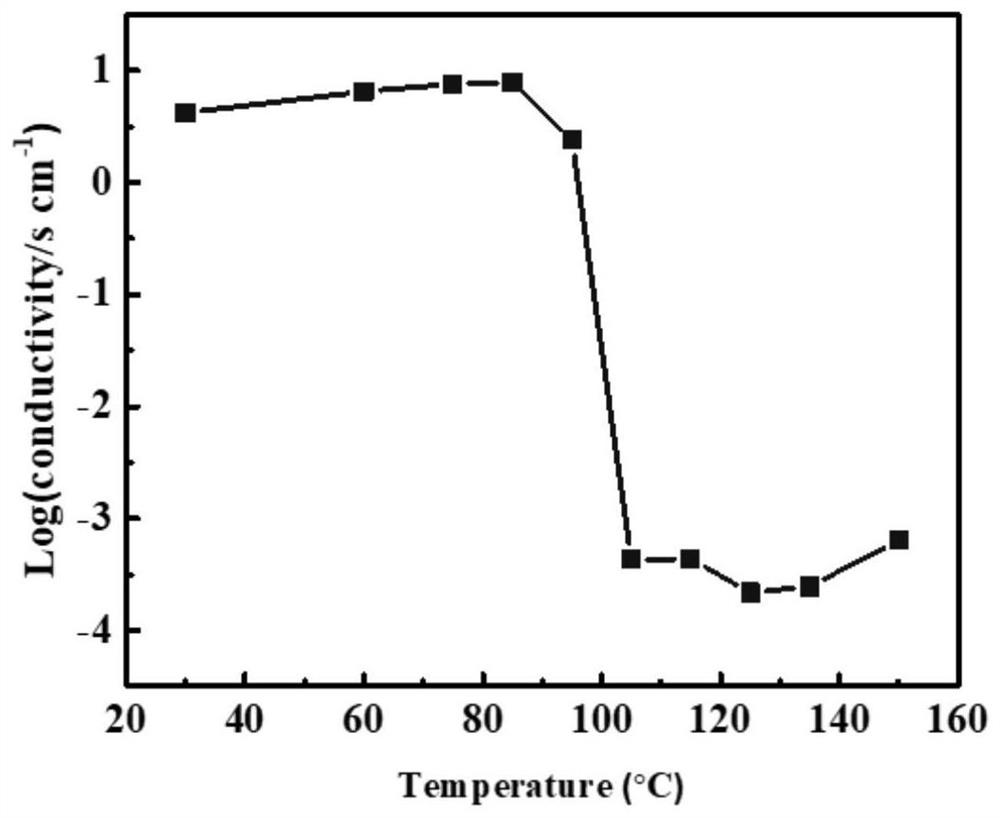

[0044]Lithium-ion batteries 1-1 to 1-11 using temperature-sensitive composite electrodes are prepared according to the following methods (referred to as LCO-P1BPy batteries):

[0045]Preparation of temperature-sensitive materials:

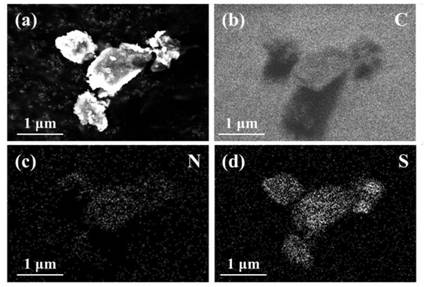

[0046]Weigh 5g of conductive material Ketjen Black (KB) and add it to concentrated nitric acid (4mol / L) and magnetically stir for 3h, then disperse the oxidized KB in 100mL deionized water ultrasonically for 60min, and add 6.3g sodium p-toluenesulfonate sequentially , 2g 1-butylpyrrole (1BPy), put it in inert gas N2Stir under magnetic force for 30min; at the same time weigh 10.09g FeCl3·6H2Dissolve O in 50mL deionized water, add it dropwise to the reaction system obtained in the above steps, and react with magnetic stirring for 4h under nitrogen protection at -5°C; then add 400mL distilled water and stir to remove excess FeCl3, Separate with a separatory funnel, repeat washing until the upper layer is colorless; add anhydrous Na2SO4Drying process to remove wat...

Embodiment 2

[0080]A temperature-sensitive composite electrode and lithium ion battery. The preparation method is roughly the same as that of Example 1, except that 1-butylpyrrole is replaced with 3-butylpyrrole.

[0081]The lithium ion battery obtained in this example was tested with reference to the method described in Example 1 for PTC effect, thermal stability, normal temperature cycle performance, and overcharge performance. The results showed that the temperature-sensitive composite electrode obtained was applied to the preparation of lithium ion batteries, and the performance Outstanding thermal stability, normal temperature cycle performance and rate discharge performance.

[0082]The PTC composite electrode provided by the present invention has good thermal stability, normal temperature cycle performance and rate discharge performance after being applied to a lithium ion battery, and can greatly improve the safety performance of the lithium ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| lift to drag ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com