Washing machine motor

A washing machine and rotor technology, applied in the field of direct-drive washing machine motors, can solve problems such as difficulty, poor structural strength, excessive wiring deviation, etc., and achieve the effects of convenient packaging and transportation, simple winding work, and improved convection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

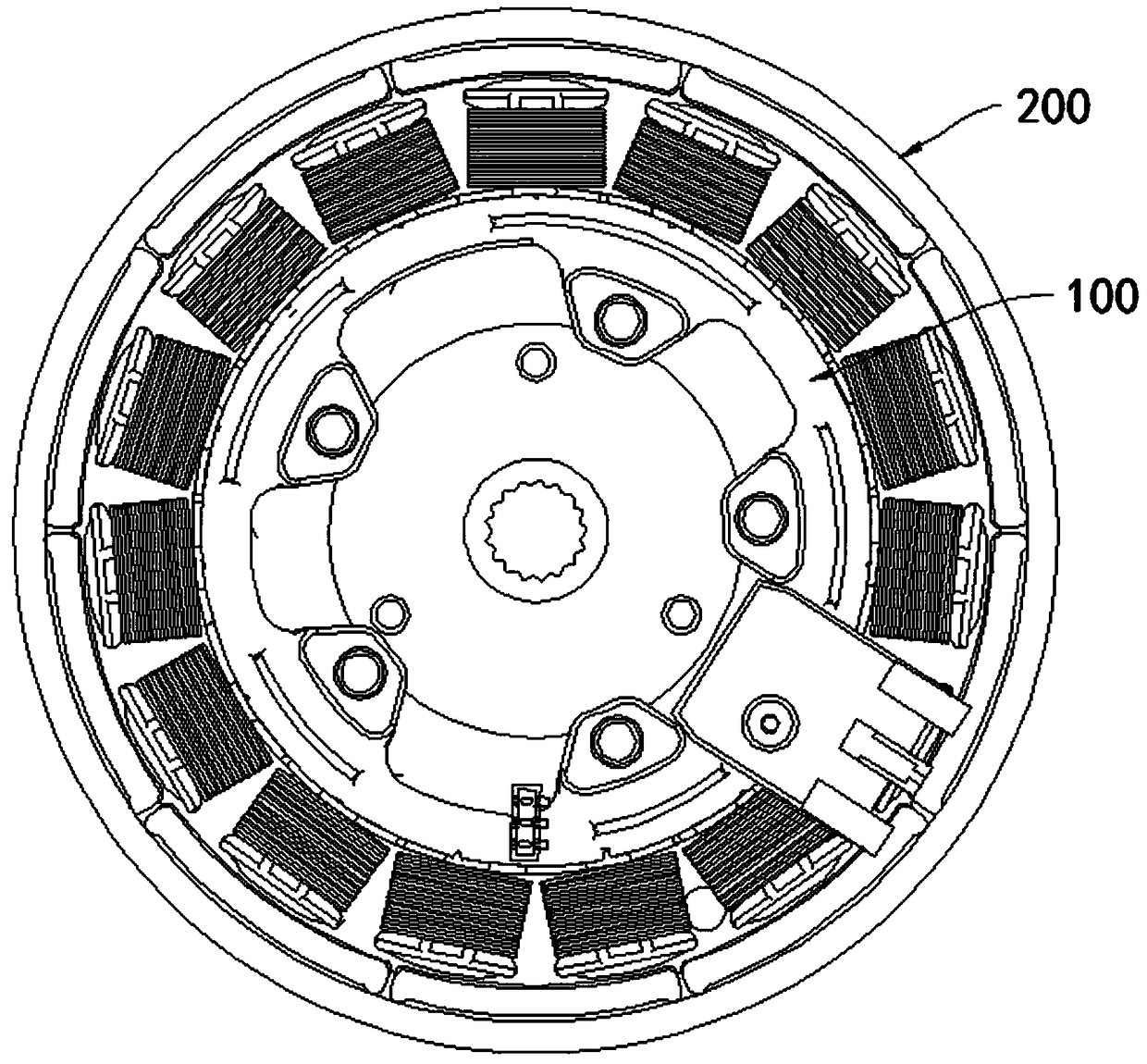

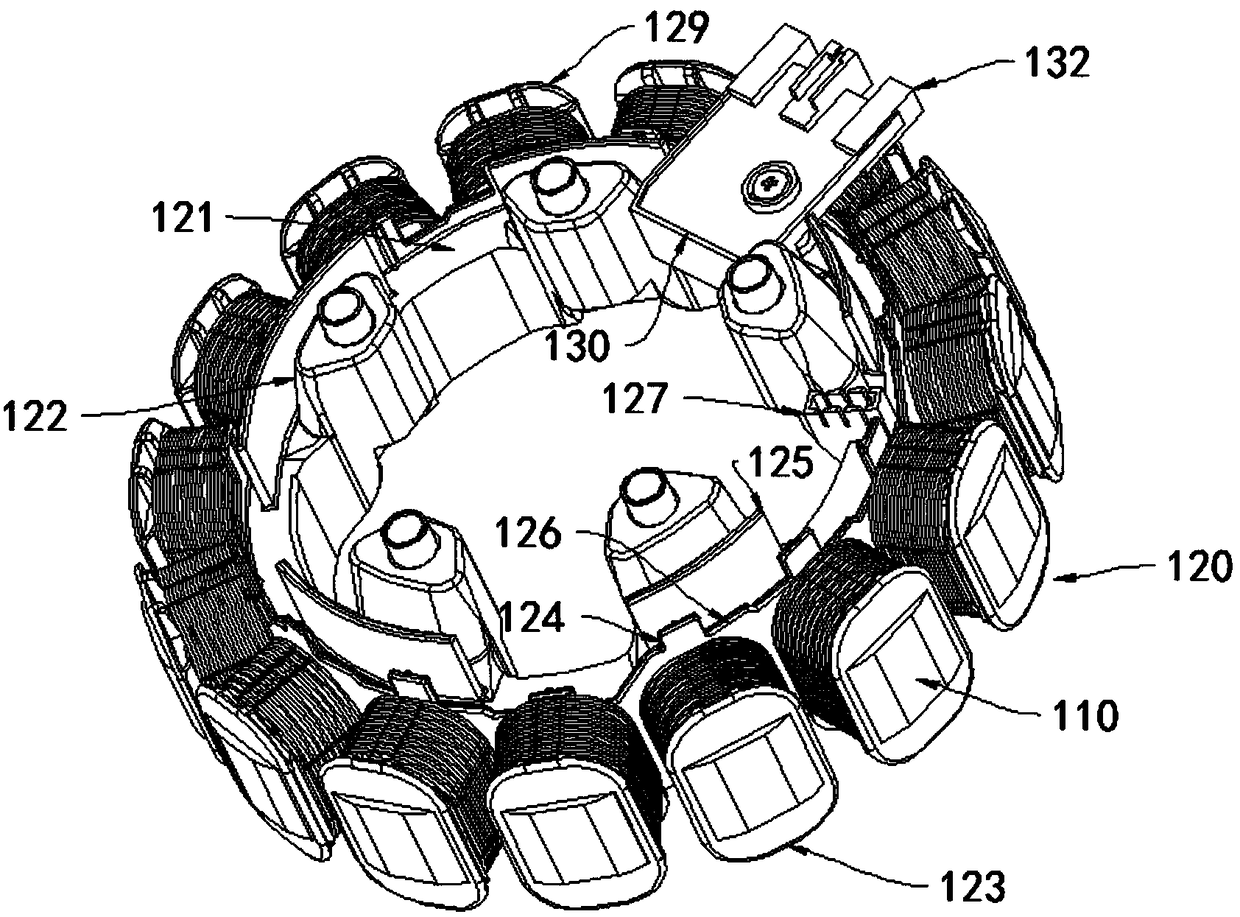

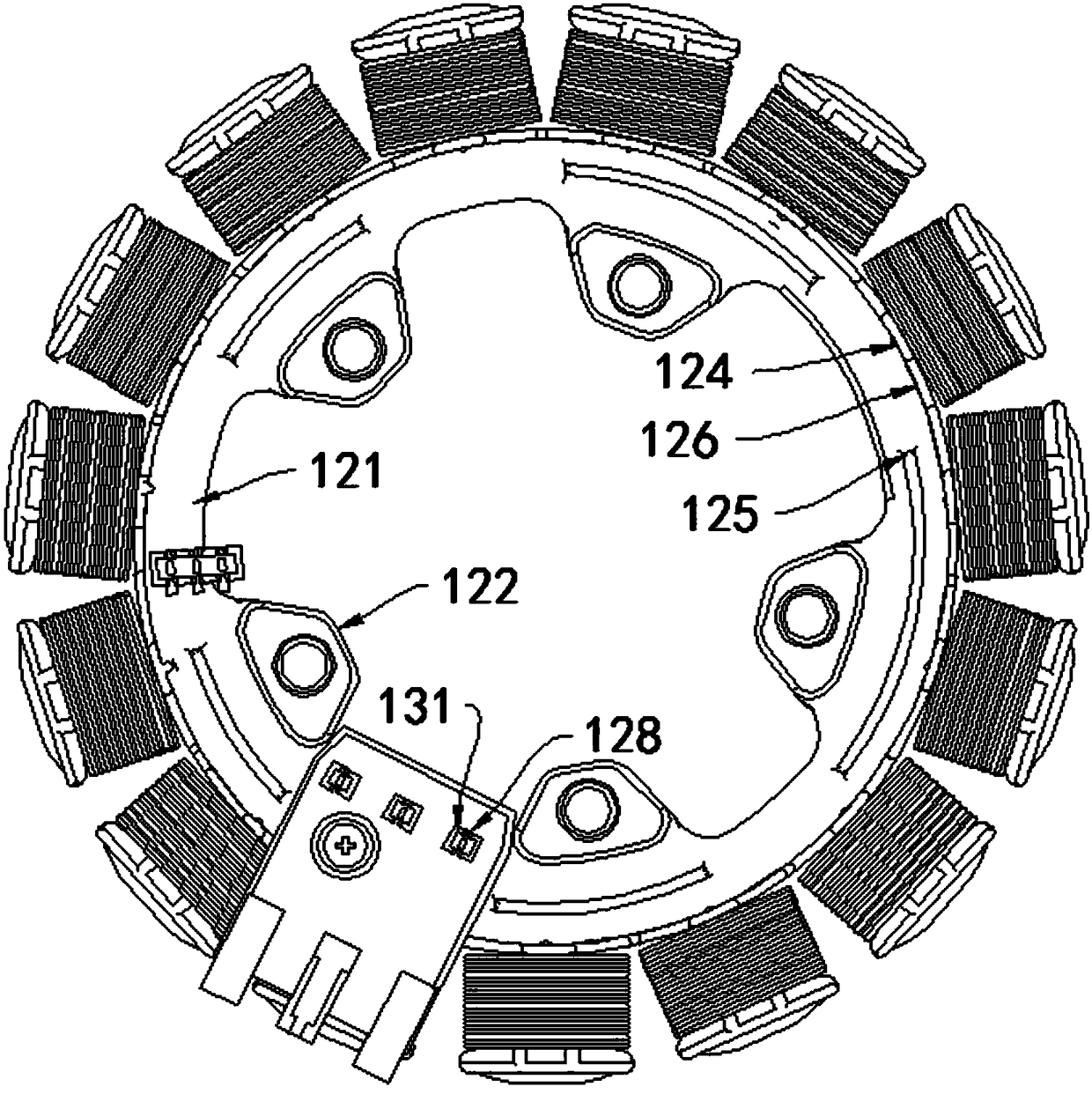

[0024] Embodiment: a kind of washing machine motor, constitutes as Figure 1 to Figure 6 As shown, it includes a drum-shaped rotor 200 and a stator 100 arranged in the rotor 200; the stator includes an iron core 110, the outer surface of the iron core 110 is provided with an injection molding body 120, and the injection molding body 120 includes a ring-shaped main body 121, The inner side wall of the main body 121 is provided with a pin seat 122, and the pin seat 122 is located near the upper end surface of the inner side wall of the main body 121; a plurality of windings 123 are evenly distributed on the outer surface of the main body 121, and the upper end surface of the main body 121 is provided with a jumper 124 and a retainer The wire board 125 and the wire blocking board 125 are located on the inner side of the wire board 124. The wire board 124 corresponds to the winding 123 one by one, and the two adjacent wire boards 124 are provided with different heights for the inco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com