Forward-flyback dual-path balanced load switching power supply circuit

A switching power supply circuit, balanced load technology, applied in electrical components, adjusting electrical variables, instruments, etc., can solve the problems of low power density, the same switching frequency, large ripple and noise interference, etc., to achieve low current stress, secondary The effect of halving the wire diameter and increasing the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

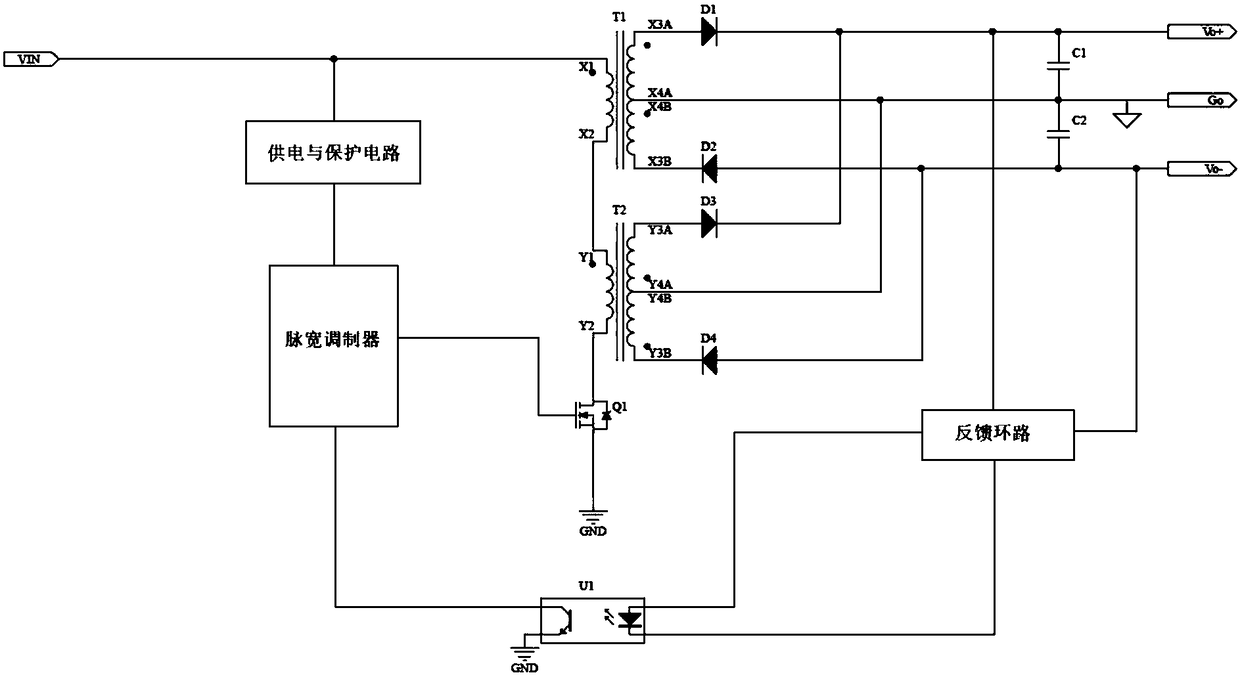

[0019] Please refer to figure 1 , the present invention proposes a forward-flyback dual-circuit balanced load switching power supply circuit, the forward-flyback dual-circuit balanced load switching power supply circuit includes: an input terminal, a first transformer T1, a second transformer T2, and a dual-channel output terminal. The first transformer T1 and the second transformer T2 convert the input direct current at the input terminal into alternating current and output it to the dual output terminals, the primary winding of the first transformer T1 is connected to the input terminal, and the first transformer T1 The primary winding of T1 is connected in series with the primary winding of the second transformer T2, and the secondary winding of the first transformer T1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com