Torsion type precision piezoelectric actuator using shear working mode and method of making the same

A technology of piezoelectric actuators and shearing work, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., and can solve the problem of insufficient precision and the types of rotary precision piezoelectric actuators Single, cumbersome production process and other problems, to achieve the effect of precise angle positioning, simple and flexible processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

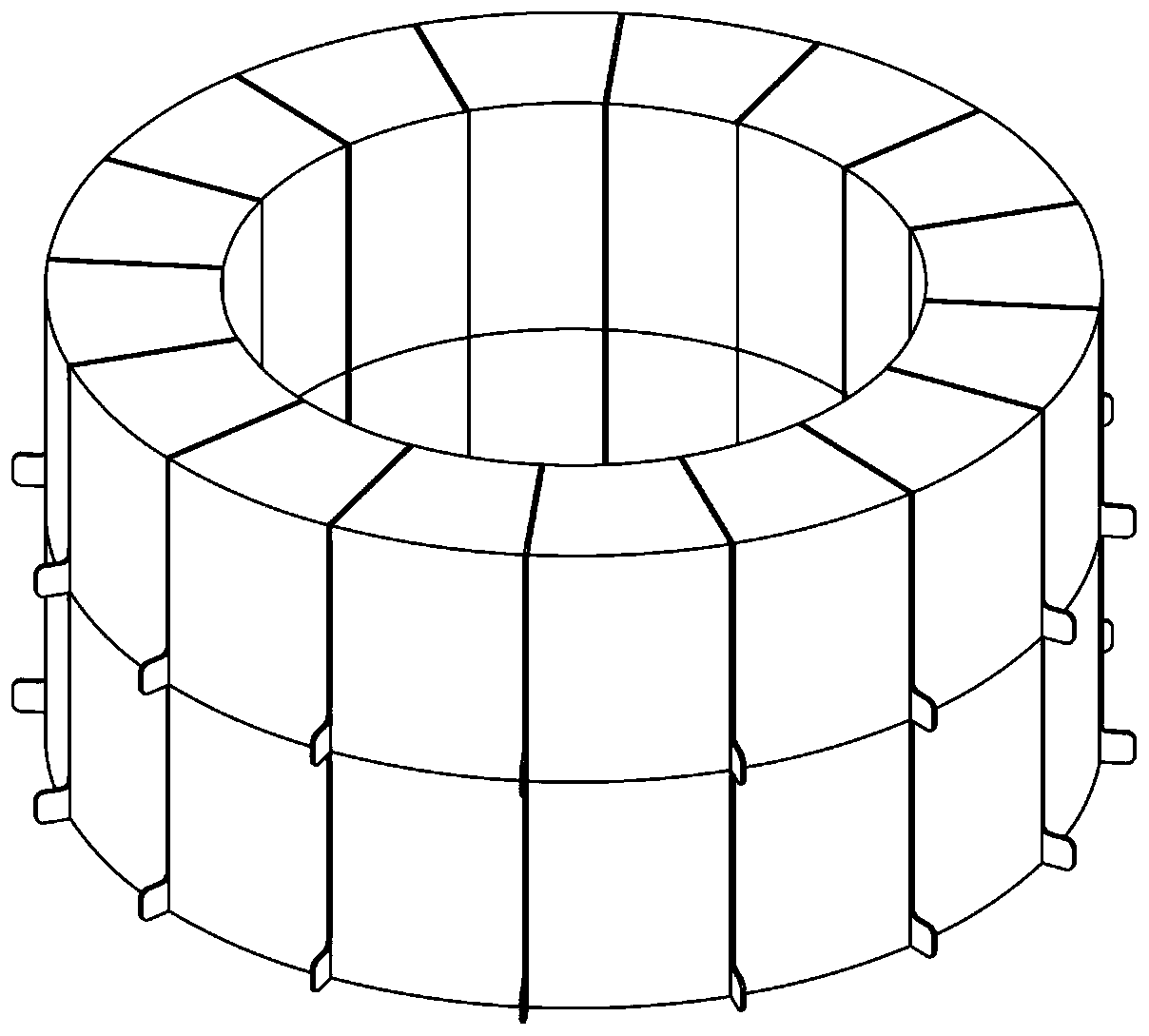

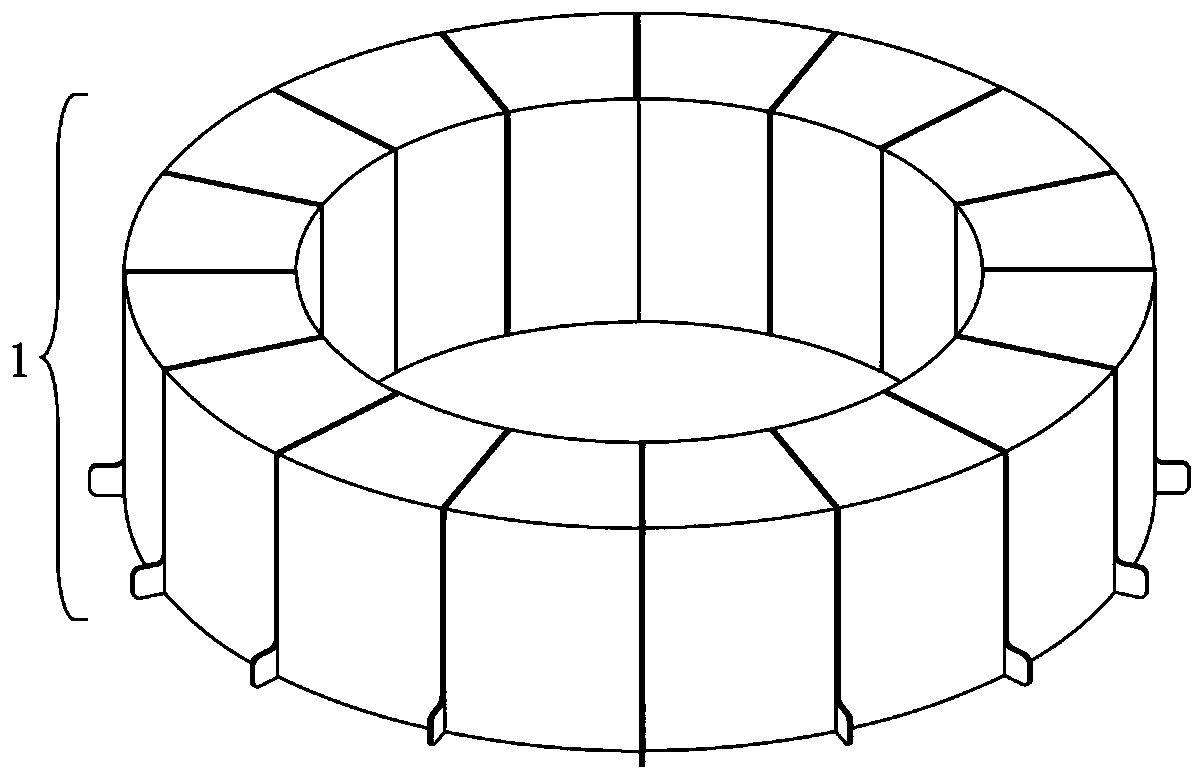

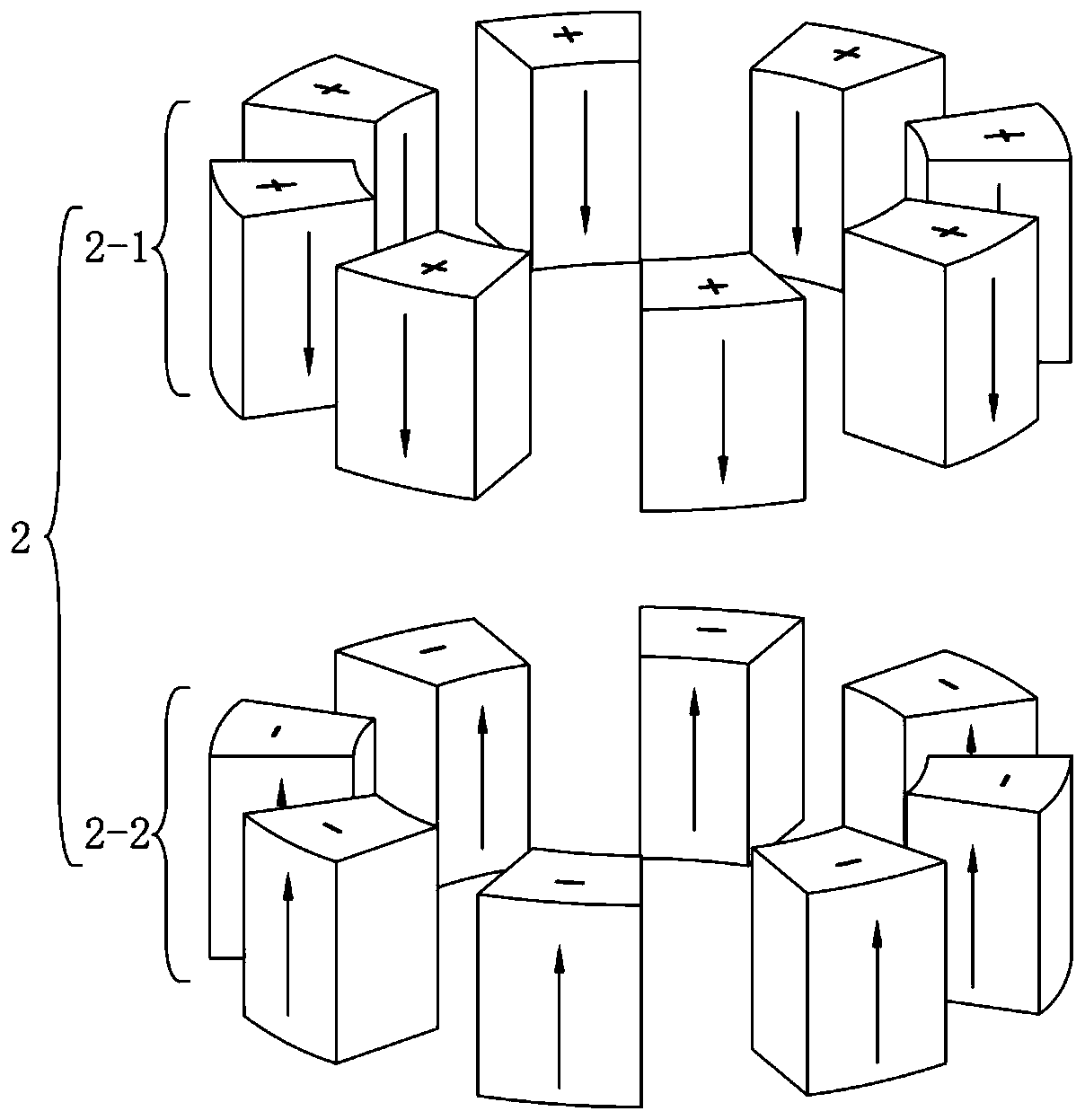

[0030] Specific implementation mode one: the following in conjunction with the description attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6This embodiment will be further described in detail. This embodiment provides a torsional precision piezoelectric driver in shear working mode in which piezoelectric ceramics are polarized along the axial direction of the driver. Its appearance is circular; the driver includes two layers of Actuating unit 1, each layer of actuating unit 1 includes 16 piezoelectric ceramics 2 and 16 energized electrode sheets 3; the cross section of the piezoelectric ceramics 2 is fan-shaped; the piezoelectric ceramics 2 includes 8 positive The polarized first piezoelectric ceramics 2-1 and the eight negatively polarized second piezoelectric ceramics 2-2 have their polarization directions along the axis of the driver and opposite to each other.

[0031] The piezoelectric ceramics 2 and the energized electrode pieces 3 are ar...

specific Embodiment approach 2

[0032] Specific implementation mode two: below in conjunction with description Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 This embodiment will be further described in detail. Similar to Embodiment 1, this embodiment provides a torsional precision piezoelectric driver in shear working mode with piezoelectric ceramics polarized along the radial direction of the driver. Its appearance is circular; the driver includes two Layers of actuating units 1 arranged radially, each layer of actuating units 1 includes 16 piezoelectric ceramics 2 and 16 energized electrode pieces 3; the cross section of the piezoelectric ceramics 2 is fan-shaped; the piezoelectric ceramics 2 The ceramic 2 includes 8 positively polarized first piezoelectric ceramics 2-1 and 8 negatively polarized second piezoelectric ceramics 2-2, and their polarization direction is along the radial direction of the driver and the polarization direction is opposite .

[0033] The piezoelec...

specific Embodiment approach 3

[0036] Specific implementation mode three: the following in conjunction with the description Figure 13 This embodiment will be further described in detail. This embodiment provides a manufacturing process flow of a torsional precision piezoelectric driver adopting a shearing working mode. This embodiment mainly includes the molding and sintering of the piezoelectric ceramic 2, the polarization of the piezoelectric ceramic 2, the machining of the piezoelectric ceramic 2 and the upper electrode, and the assembly of the piezoelectric ceramic 2 and the energized electrode sheet 3 into a layer of the driver. Process of actuating unit 1.

[0037] The molding and sintering of the piezoelectric ceramic 2 may include processes such as batching, mixing, pre-firing, crushing, molding, debinding, and sintering according to different process equipment. Electroceramic blanks are used for subsequent polarization and processing. The polarization of the piezoelectric ceramic 2 needs to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com