Kidney bean cultivation frame

A cultivation rack and green bean technology, applied in drinking water installations, plant support, gardening, etc., can solve the problems of reducing the growth rate of green bean seedlings, small climbing area of green beans, affecting the growth of green beans, etc. The effect of avoiding direct sunlight and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

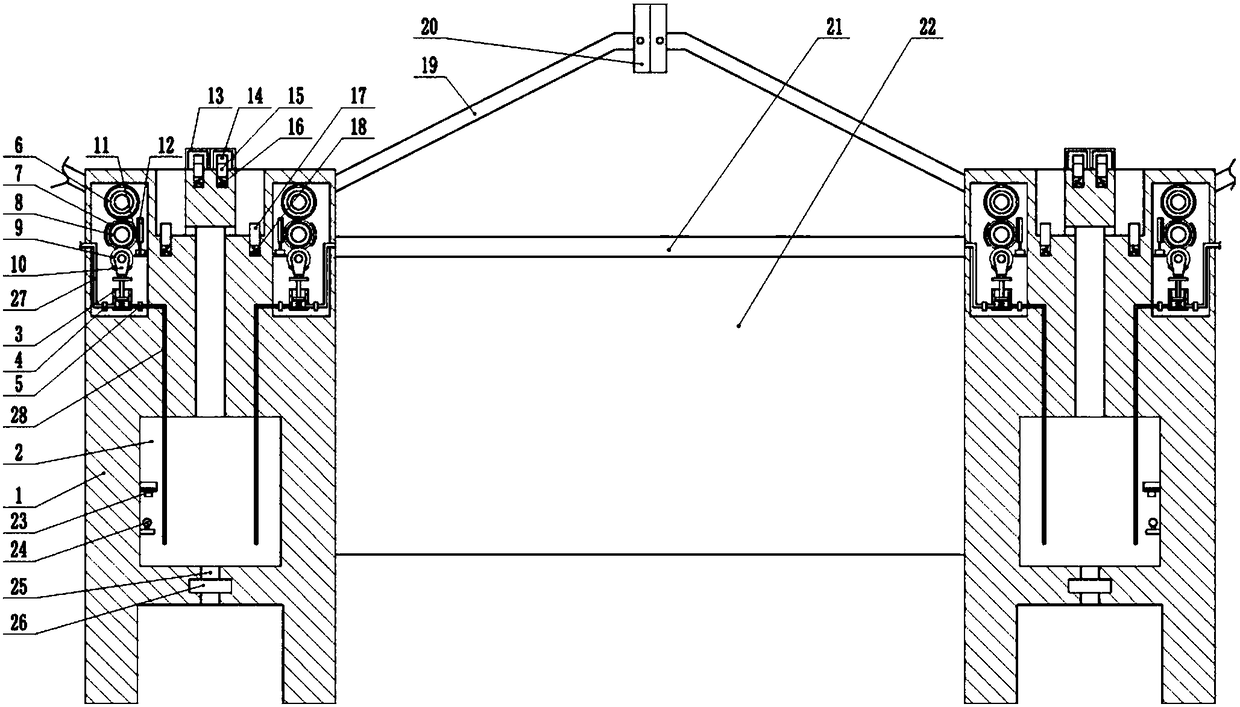

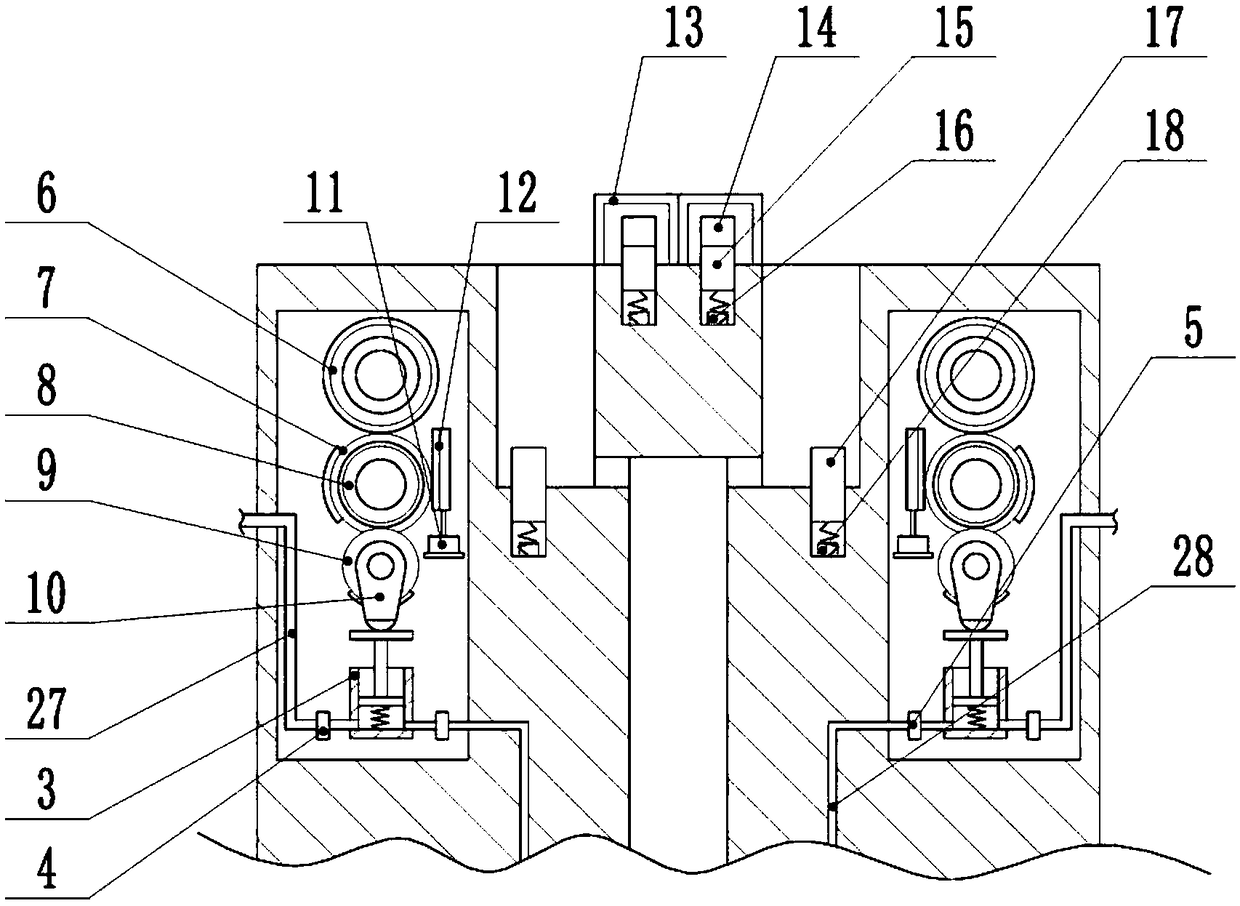

[0021] The reference signs in the drawings of the description include: column 1, water storage cavity 2, piston cylinder 3, second one-way valve 4, first one-way valve 5, first gear 6, first sector gear 7, second Gear 8, second fan gear 9, cam 10, cylinder 11, rack 12, transparent rain cover 13, rubber air bag 14, touch rod 15, second button 16, slide bar 17, first button 18, swing bar 19 , Reach plate 20, spray pipe 21, planting net 22, the 3rd button 23, float 24, drainpipe 25, drain valve 26, outlet pipe 27, water inlet pipe 28.

[0022] The embodiment is basically as attached figure 1 and figure 2As shown: the green bean cultivation frame, including two uprights 1 and planting net 22, the planting net 22 is clamped between the two uprights 1, each upright 1 is rotatably connected with a rotating shaft, and the rotating connection between the rotating shaft and the upright 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com