Horizontal magnetic field type vertical-ring high gradient magnetic separator

A high-gradient magnetic separator and magnetic field technology, applied in high-gradient magnetic separators and other directions, can solve the problems of low background magnetic field strength, inability to classify adsorption, and large separation air gap, so as to improve the separation effect and the utilization of magnetic energy. efficiency, improving the sorting effect and magnetic energy utilization rate, and reducing the effect of magnetic media clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

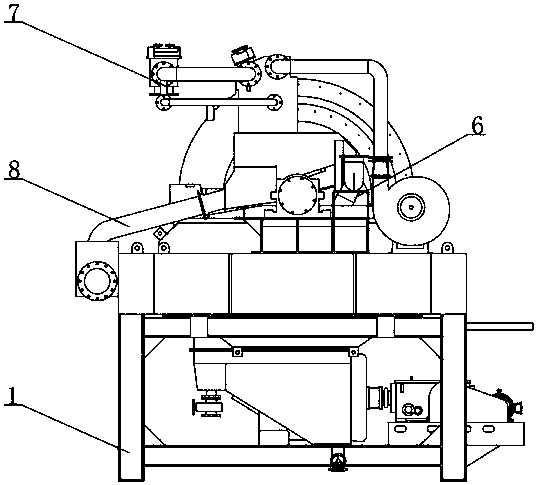

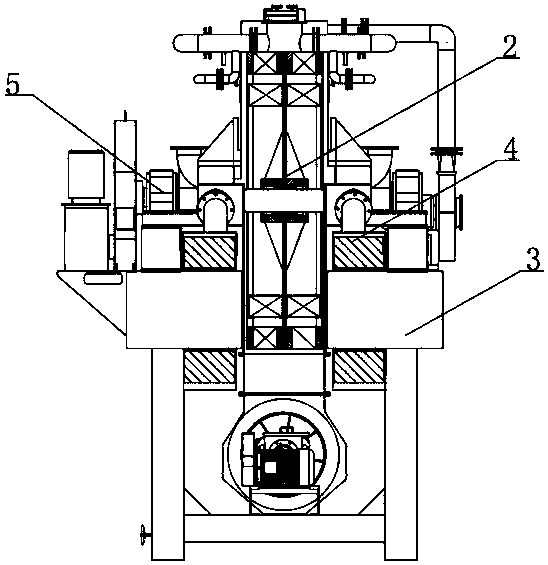

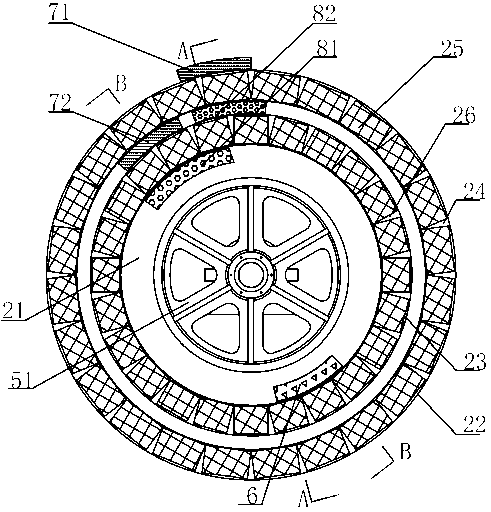

[0033] Such as Figure 1 to Figure 7Shown is the first embodiment of the horizontal magnetic field vertical ring high-gradient magnetic separator of the present invention, including a frame 1, a sorting ring 2 containing magnetic media, a magnetic system 3 fixed on the frame 1, and a magnetic system surrounded by The excitation coil 4 on the 3, the drive mechanism 5 for driving the sorting ring to rotate, the feeding device 6 arranged above the sorting ring 2, the washing device 7 for washing the coarse and fine magnetic materials and the coarse and fine magnetic materials for receiving the sorting The material receiving device 8 for granular magnetic materials, the drive mechanism 5, the feeding device 6, the washing device 7 and the material receiving device 8 are all arranged on the frame 1; A sorting space is formed, and the sorting ring 2 is arranged in the sorting space; the excitation coil 4 cooperates with the magnetic system 3 to form a background magnetic field in wh...

Embodiment 2

[0041] Such as Figure 8 Shown is the second embodiment of the horizontal magnetic field vertical ring high gradient magnetic separator of the present invention, this embodiment is similar to the first embodiment, the difference is that the thickness of the intermediate ring 21 increases radially from outside to inside in two stages , the middle ring 21 includes a first ring and a second ring, the first ring is connected to the outside of the second ring, the thickness of the second ring is greater than the thickness of the first ring; the outer ring includes a first outer ring 22 and a second outer ring 23 , the first ring is embedded inside the first outer ring 22 , and the second ring is embedded inside the second outer ring 23 . The first magnetic field sorting area is formed between the first ring and the first outer ring 22, the second magnetic field sorting area is formed between the second ring and the second outer ring 23, and the magnetic field strength of the first ...

Embodiment 3

[0043] Such as Figure 7 Shown is the third embodiment of the horizontal magnetic field vertical ring high-gradient magnetic separator of the present invention. This embodiment is similar to Embodiment 1, the difference is that in order to increase the stability of the distribution of the induced magnetic field intensity in the sorting space, in the The two sides of an outer ring 21 and a second outer ring 22 are respectively surrounded by a first thickened layer and a second thickened layer made of magnetic permeable material. The best uniform effect is obtained when the total thickness of the first thickened layer and the total thickness of the second thickened layer are respectively equal to the thickness of the first ring and the second ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com