Ultra-long deep woodworking drilling machine and implementing method thereof

A woodworking drilling and depth technology, which is applied to fixed drilling machines, wood processing equipment, manufacturing tools, etc., can solve the problems of high wood waste rate, inability to drill holes, restrictions, etc., and achieve low utilization rate, ensure accuracy, and save money. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

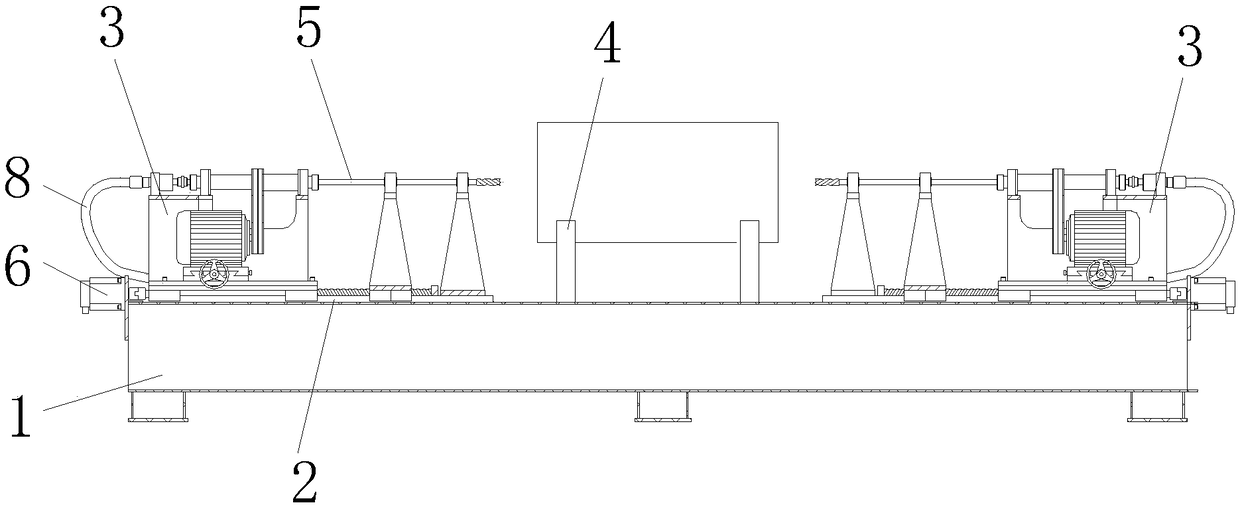

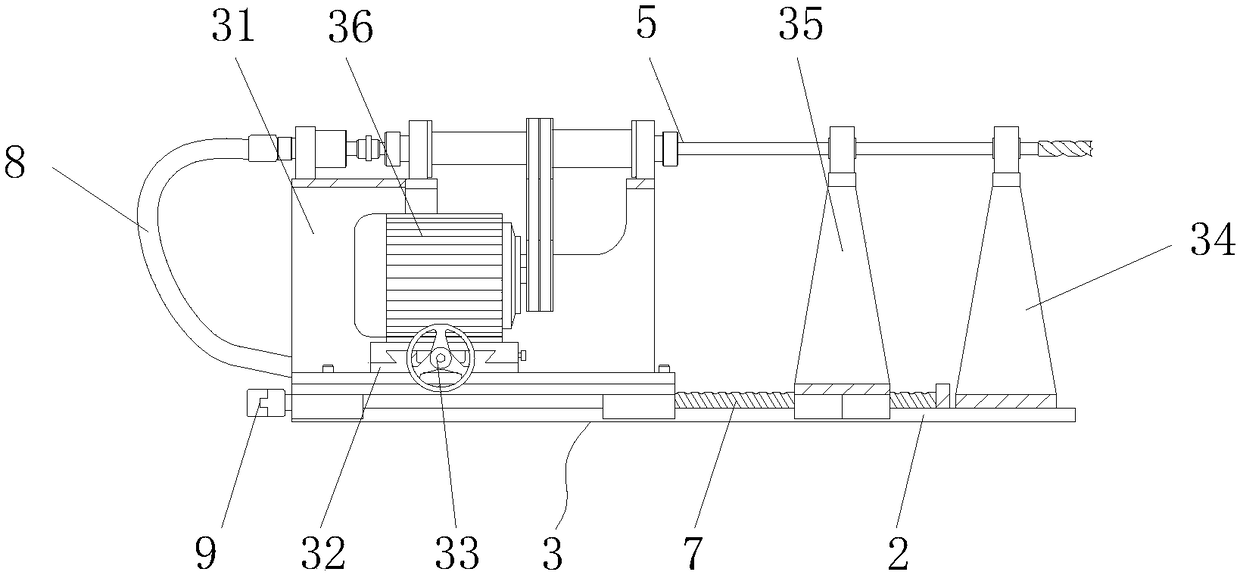

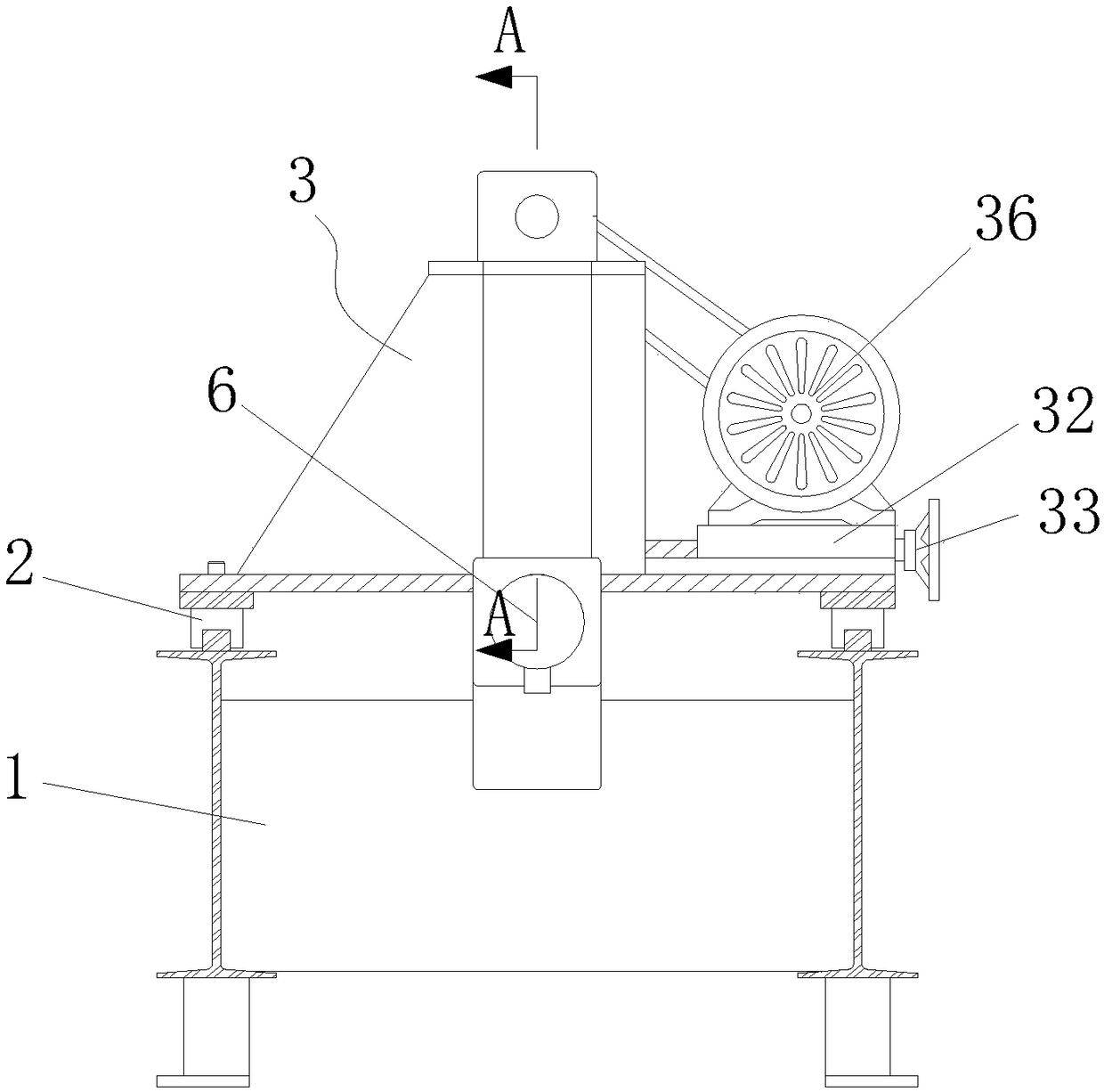

[0033] see Figure 1-6 , the present invention provides the following technical solutions: a super-long depth woodworking drilling machine, comprising a drilling machine support 1 and a wood fixing frame 4 fixed on the upper surface of the drilling machine support 1, the upper surface of the drilling machine support 1 is welded on one side of the wood fixing The guide rail 2 is slidingly connected with the mobile assembly 3, and the top of the mobile assembly 3 is connected with the hollow drill shaft assembly 5 through the rotation of the bearing seat. A hollow twist drill bit 10 is connected to one end of the shaft assembly 5 near the wood fixing frame 4 .

[0034]Further, the moving assembly 3 includes a drill shaft base 31, a dovetail carriage 32, a belt adjustment handwheel 33, a fixed center frame 34, a moving balance center frame 35 and a drill shaft motor 36, wherein one side of the drill shaft base 31 is welded with The dovetail carriage 32, the base of the drill sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com