A temperature-controllable 3D printing nozzle with automatic adjustment of the discharge mode

An automatic adjustment, 3D printing technology, applied in the field of 3D printing, can solve the problems of uneven heating of biological materials, cell death, deviation of biological 3D structure from the expected structure, etc., to avoid uneven heating, avoid cell death, and improve printing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

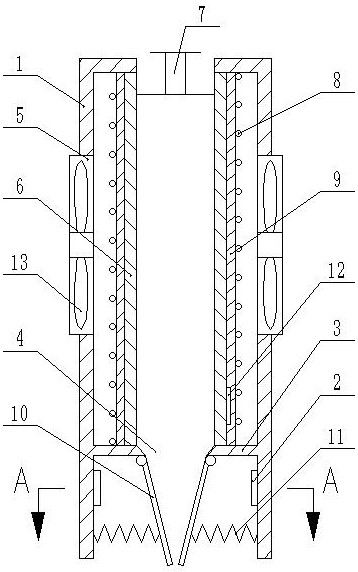

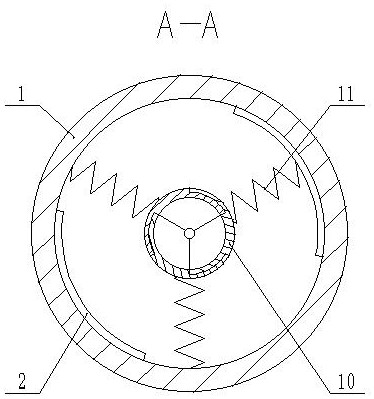

[0025] Such as figure 1 — image 3 As shown, a temperature-controllable 3D printing nozzle of the present invention that automatically adjusts the discharge mode includes: a nozzle housing 1, a biological charging module, a temperature control module, a nozzle diameter control module and an applied electric field electrode sheet 2;

[0026] The nozzle casing 1 is a hollow cylinder with an open bottom and a hole in the center of the top. The circular fixing plate 3 is fixed on the middle and lower part of the inner wall of the nozzle casing 1 to form a discharge port 4. There are two symmetrically distributed nozzles on the nozzle casing 1. The cooling holes 5;

[0027] The biological charging module includes a charging barrel 6 and an extruding piston 7. The charging barrel 6 is a hollow circular tube concentrically set inside the nozzle housing 1 and fixed on the circular fixing plate 3, and the extruding piston 7 is set on the In the charging barrel 6;

[0028] The temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com