Inner core mold for preparing thin-wall arc composite pipe and preparation method of arc pipe

A composite material tube and inner mandrel technology, which is applied in applications, household appliances, tubular objects, etc., can solve the problems of poor durability of foam mandrel, difficulty in demoulding silicone rods, and affecting product performance, so as to reduce porosity and guarantee Overall, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

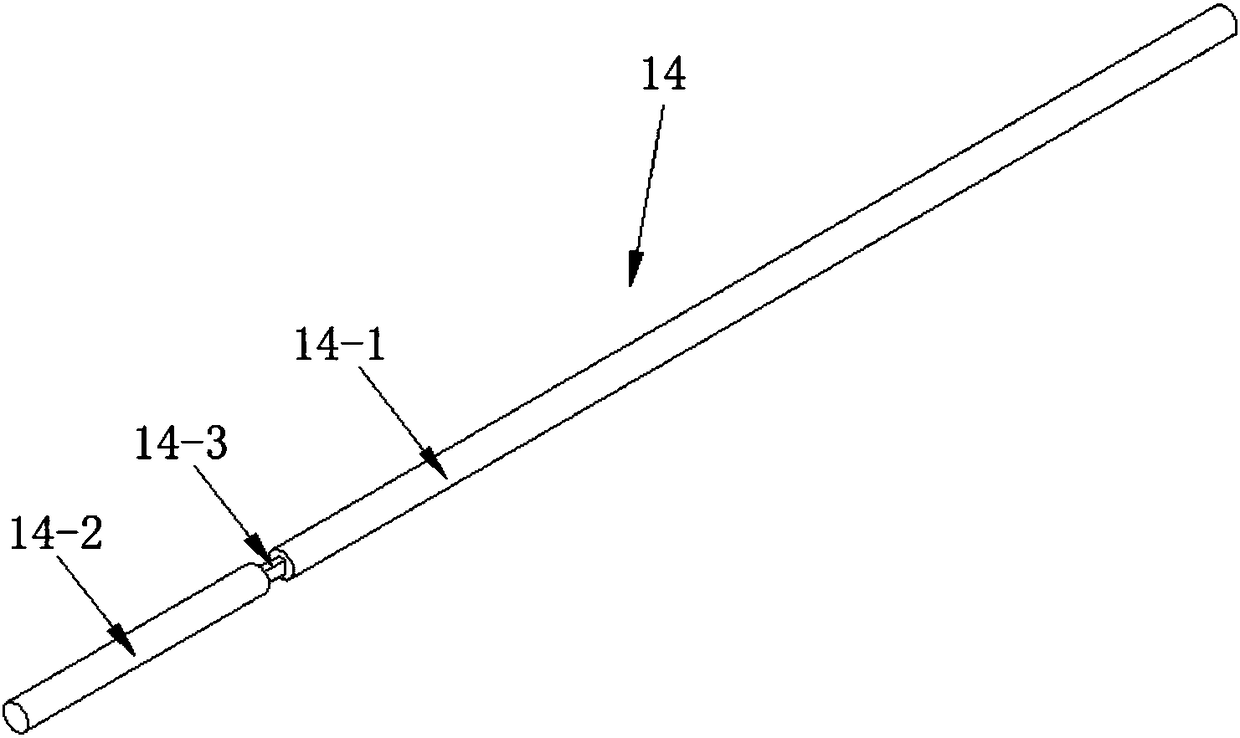

[0045] Such as figure 1 Shown, a kind of inner mandrel that is used to prepare thin-walled curved composite pipe, described inner mandrel 14 is rigid inner mandrel, and described inner mandrel 14 is used for preparing thin-walled arcuate pipe, used The shape of the inner core mold 14 is a cylinder. The rigid inner mandrel can be an inner mandrel made of rigid materials such as metal pipe or metal mandrel or plastic pipe or plastic core material.

[0046] In order to facilitate the demoulding of the prefabricated body, such as figure 1 As shown, the inner mandrel 14 includes an inner mandrel main body 14-1 and a demoulding part 14-2, the inner mandrel main body 14-1 is provided with an insert block 14-3, and the demoulding part 14-2 is provided with The groove, the inner core mold main body 14-1 and the demoulding part 14-2 are detachably connected through the cooperation of the insert block 14-3 and the groove.

[0047] A method for preparing a thin-walled arc-shaped compos...

Embodiment 2

[0077] An inner mandrel for preparing a thin-walled arc-shaped composite pipe, the inner mandrel is a rigid inner mandrel, and the inner mandrel is used for preparing a thin-walled arc-shaped pipe, and the shape of the inner mandrel used is It is a truncated cone, and the angle of the truncated cone is greater than 0° and less than or equal to 10°, which is not shown in the structural diagram. The angle of the truncated cone here refers to the angle between the central line of the truncated cone and its generatrix. The rigid inner mandrel can be an inner mandrel made of rigid materials such as metal pipe or metal mandrel or plastic pipe or plastic core material. When the angle of the frustum is equal to 0°, the frustum transforms into a cylinder.

[0078] A method for preparing a thin-walled arc-shaped composite material tube, comprising the steps of:

[0079] Step S1, surface treatment of the inner mandrel: apply sealing agent and mold release agent on the surface of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com