Rear single ducted fan type composite wing aircraft with zero thrust composite ailerons

A ducted fan and composite wing technology is applied in the field of aircraft equipment and rear single ducted fan-type composite wing aircraft, which can solve the problems of low wing structure strength, slow horizontal flight speed, and unsatisfactory controllability, etc. Achieve the effect of expanding the wing area, fast flight speed, and reducing one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

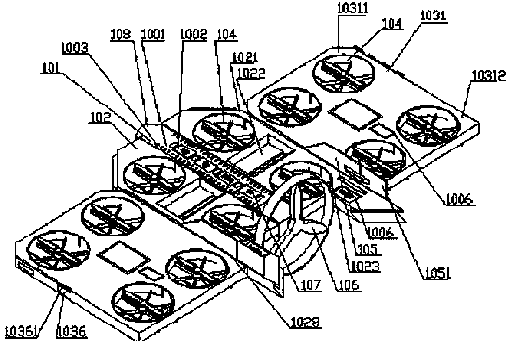

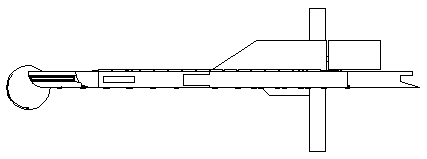

[0028] Such as figure 1 As shown, a rear single-duct fan-type compound-wing aircraft with no-thrust composite auxiliary wing is characterized in that the rear single-duct fan-type compound-wing aircraft and the non-thrust self-powered compound wing assembled on both sides of its wing Aileron composition;

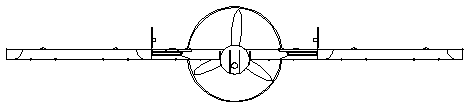

[0029] Wherein, the rear single-duct fan type composite wing aircraft includes a body 101, a composite lift wing 102 and a propeller 106 fixedly installed on both sides of the body 101; wherein, the body 101 is set as a deck platform; the The composite lift wing 102 has a built-in self-enclosed ducted fan 104, and a wing hinge 1028 is designed on the outside of the composite lift wing 102; the propeller 106 is a ducted fan propeller;

[0030] The non-thrust self-powered composite aileron is provided with a self-enclosed ducted fan 104, and one or both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com