Material cutting door of vertical screw conveyer loading bowl machine

An auger and vertical technology, applied in the field of reclaiming equipment, can solve the problems of unclean environment and pollution in the production line, and achieve the effect of compact structure, less space occupation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

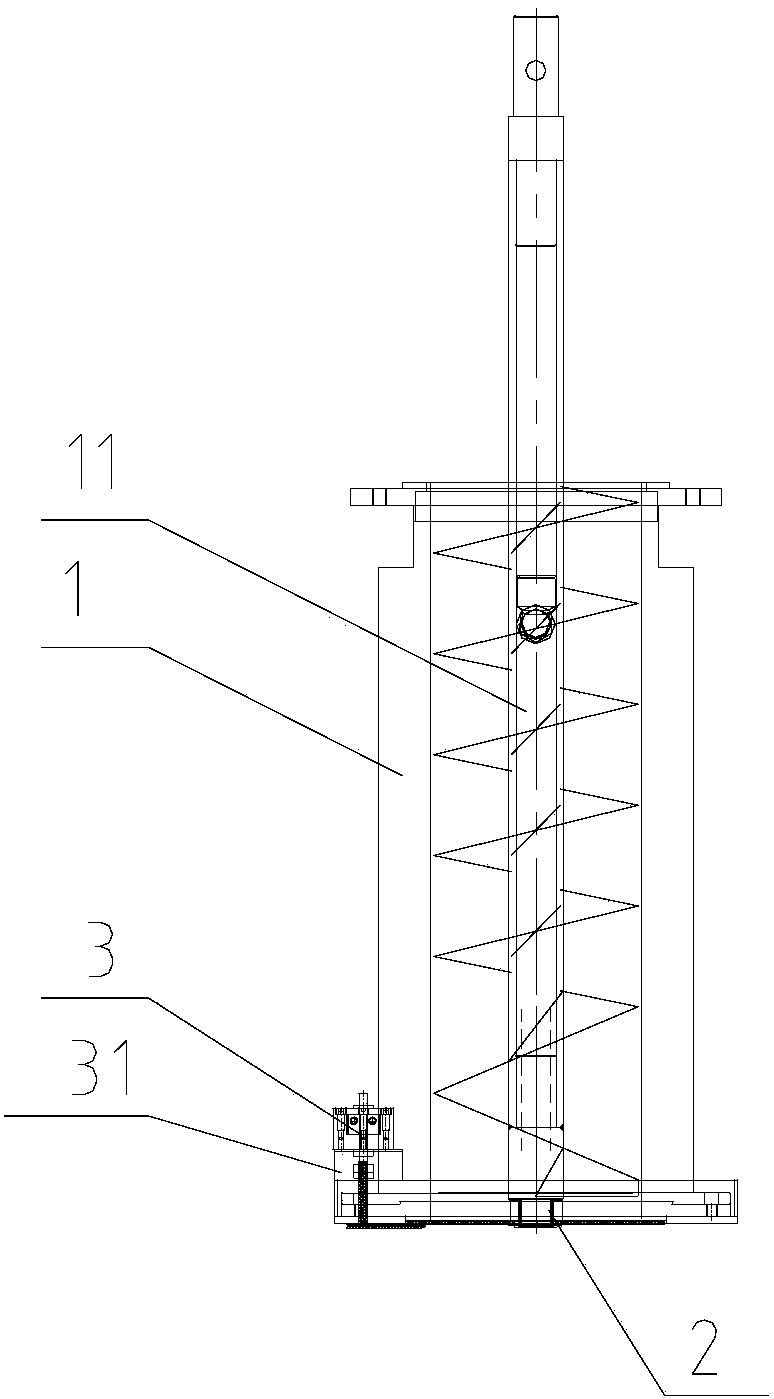

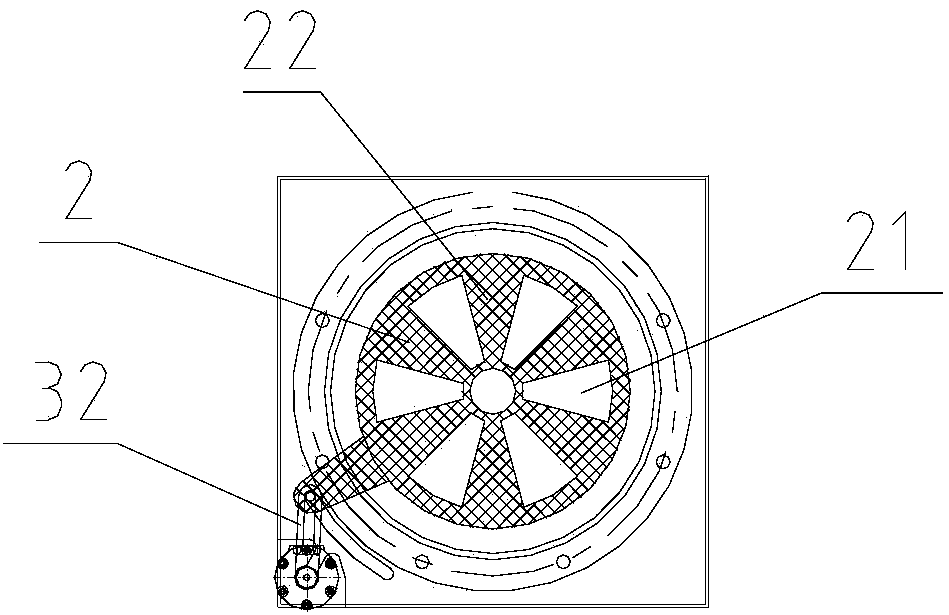

[0020] Such as figure 1 and 2 As shown, a cutting door of a vertical auger bowl loading machine is arranged on the lower end surface of the vertical auger, and includes a cutting door 2 and a driving device. The cutting door 2 includes a two-layer rotary blade structure, and the upper rotary blade 21 is fixed on the bottom end of the auger tube 1, and the side of the upper rotary vane 21 is fixedly connected with the wall of the auger tube 1; the lower rotary vane 22 is coaxially connected with the upper rotary vane 21, and both can rotate around the axis; The side of the lower rotary vane 22 is connected with a driving device, and the driving device drives the lower rotary vane 22 to rotate.

[0021] The cutting door of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com