Water-based magnetic blackboard paint and preparation method thereof

A magnetic and blackboard technology, applied in the direction of magnetic coatings, coatings, etc., can solve the problems of inconvenient use and construction, hazards to health, and lack of adsorption of magnetic objects, etc., to achieve broadened functionality, good scrub resistance, and good hydrophobicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of water-based magnetic blackboard paint comprises the steps of uniformly mixing components.

[0037] Preferably, the preparation method is:

[0038]①Put water, dispersant, preservative, antifungal agent, soft magnetic powder, and filler into the sand mill, grind at a speed of 300-800 rpm for 10-60 minutes, and obtain a slurry dispersed by ball milling. After grinding and dispersing, the median particle size of the powder in the slurry is less than 30 μm;

[0039] ② After step ① is completed, transfer the slurry dispersed by the ball mill to the stirring disperser;

[0040] ③ After step ② is completed, add film-forming resin during the stirring and dispersing process; the stirring speed is 20-50 rpm, the dispersion speed is 200-500 rpm, and the stirring and dispersing time is 30-60 minutes;

[0041] ④ After step ③ is completed, add film-forming aids, defoamers, thickeners, and antifreeze during the stirring and dispersing process. The stirring spe...

Embodiment 1

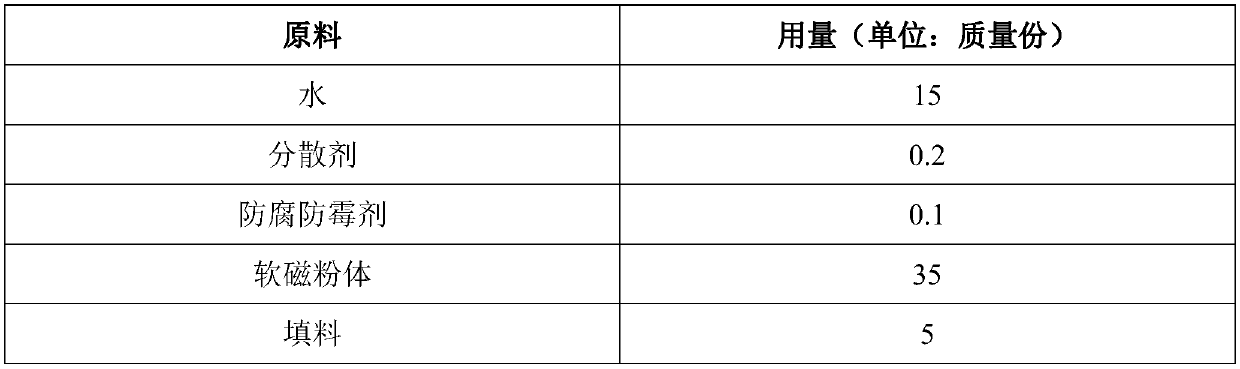

[0044] A kind of water-based magnetic blackboard paint, its formula is as follows:

[0045] Table 1:

[0046]

[0047]

[0048] A preparation method of water-based magnetic blackboard paint, comprising steps:

[0049] ①Put 15 parts of water, 0.2 parts of dispersant, 0.1 part of anti-corrosion and anti-mold agent, 35 parts of soft magnetic powder, and 5 parts of filler in parts by weight into the sand mill, and grind for 10 minutes at a speed of 400 rpm Finally, the slurry after ball milling and dispersion is obtained, and the median particle size of the powder in the slurry after grinding and dispersion is less than 30 μm;

[0050] ② After step ① is completed, transfer the slurry dispersed by the ball mill to the stirring disperser;

[0051] ③ After step ② is completed, add 40 parts of film-forming resin in the process of stirring and dispersing. The stirring speed is 30 rpm, the dispersion speed is 200 rpm, and the stirring and dispersing time is 40 minutes.

[0052]...

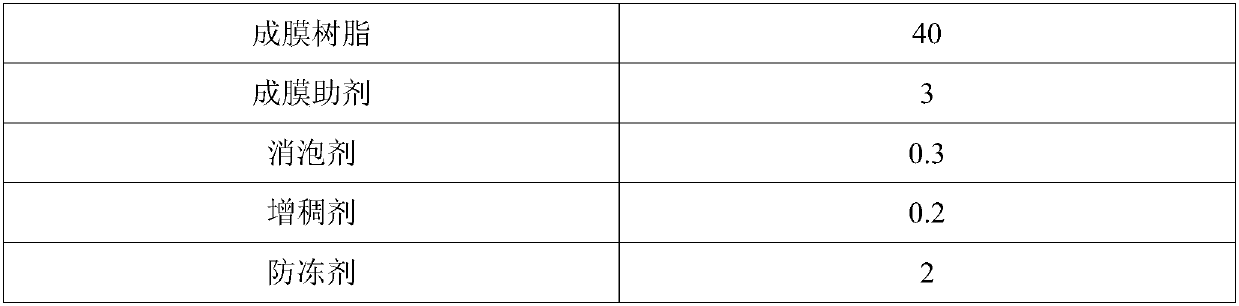

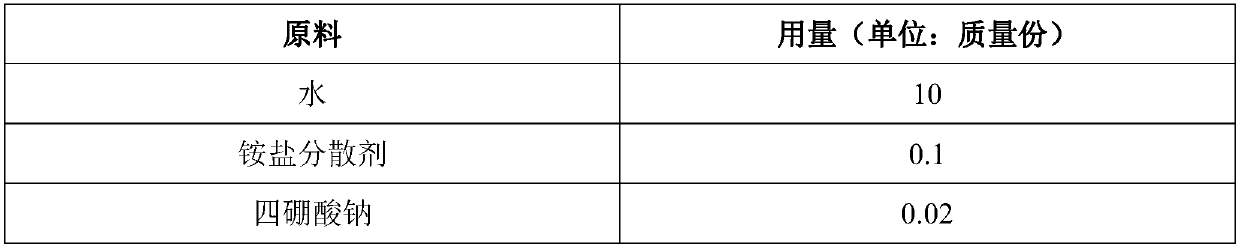

Embodiment 2

[0060] A kind of water-based magnetic blackboard paint, its formula is as follows:

[0061] Table 2:

[0062] raw material

Dosage (unit: parts by mass)

water

15

Dispersant

0.2

Antiseptic and antifungal agent

0.1

Soft magnetic powder

32

filler

5

Film-forming resin

40

Coalescent

3

0.3

thickener

0.2

2

[0063] A preparation method of water-based magnetic blackboard paint, comprising steps:

[0064] ① Add 15 parts by weight of water, 0.2 parts of dispersant, 0.1 part of anti-corrosion and anti-mold agent, 32 parts of soft magnetic powder, and 5 parts of filler into the sand mill, and grind for 10 minutes at a speed of 400 rpm Finally, the slurry after ball milling and dispersion is obtained, and the median particle size of the powder in the slurry after grinding and dispersion is less than 30 μm;

[0065] ② After step ① is completed, transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com