Detection device, control system and control method for wheel greasing track of sintering machine trolley

A technology of detection device and distance measuring device, which is applied to measurement devices, optical devices, mechanical equipment, etc., can solve the problems of time-consuming and low work efficiency in the fatliquoring process, and achieve the effect of accurate and reliable calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

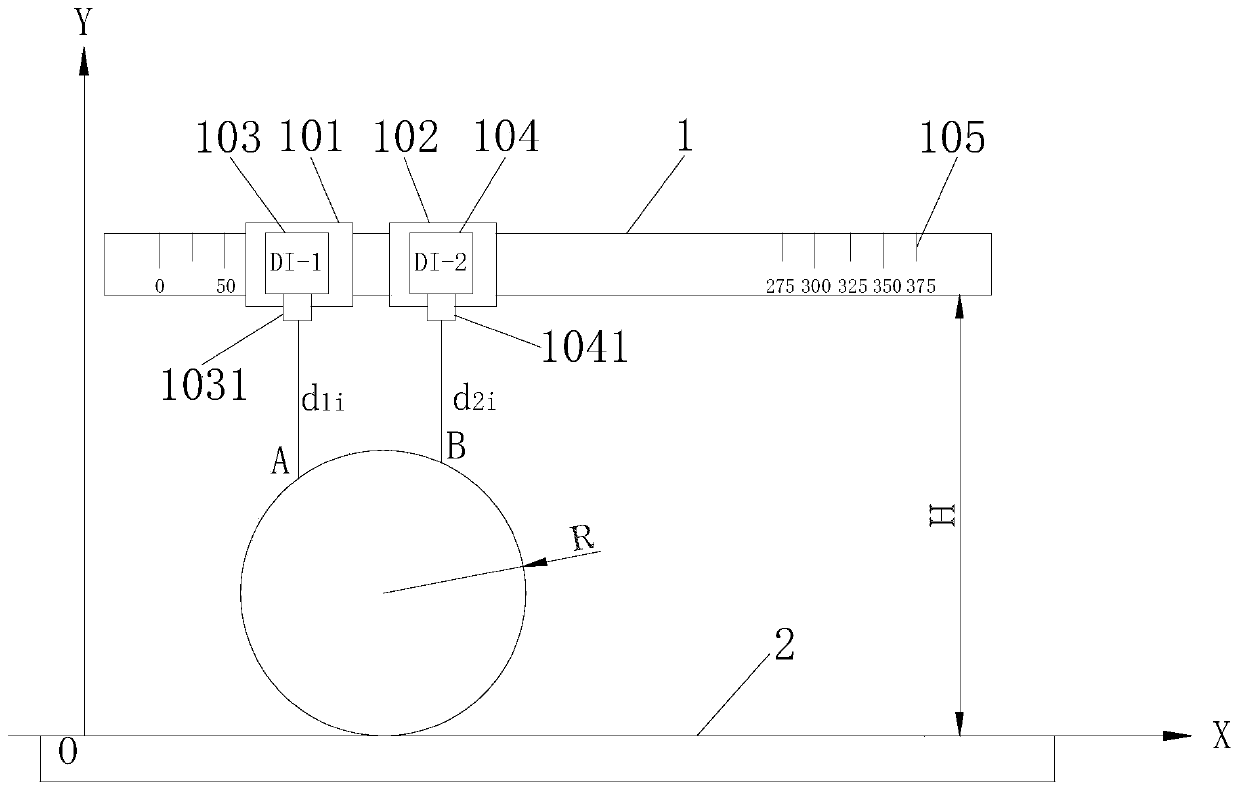

Embodiment 1

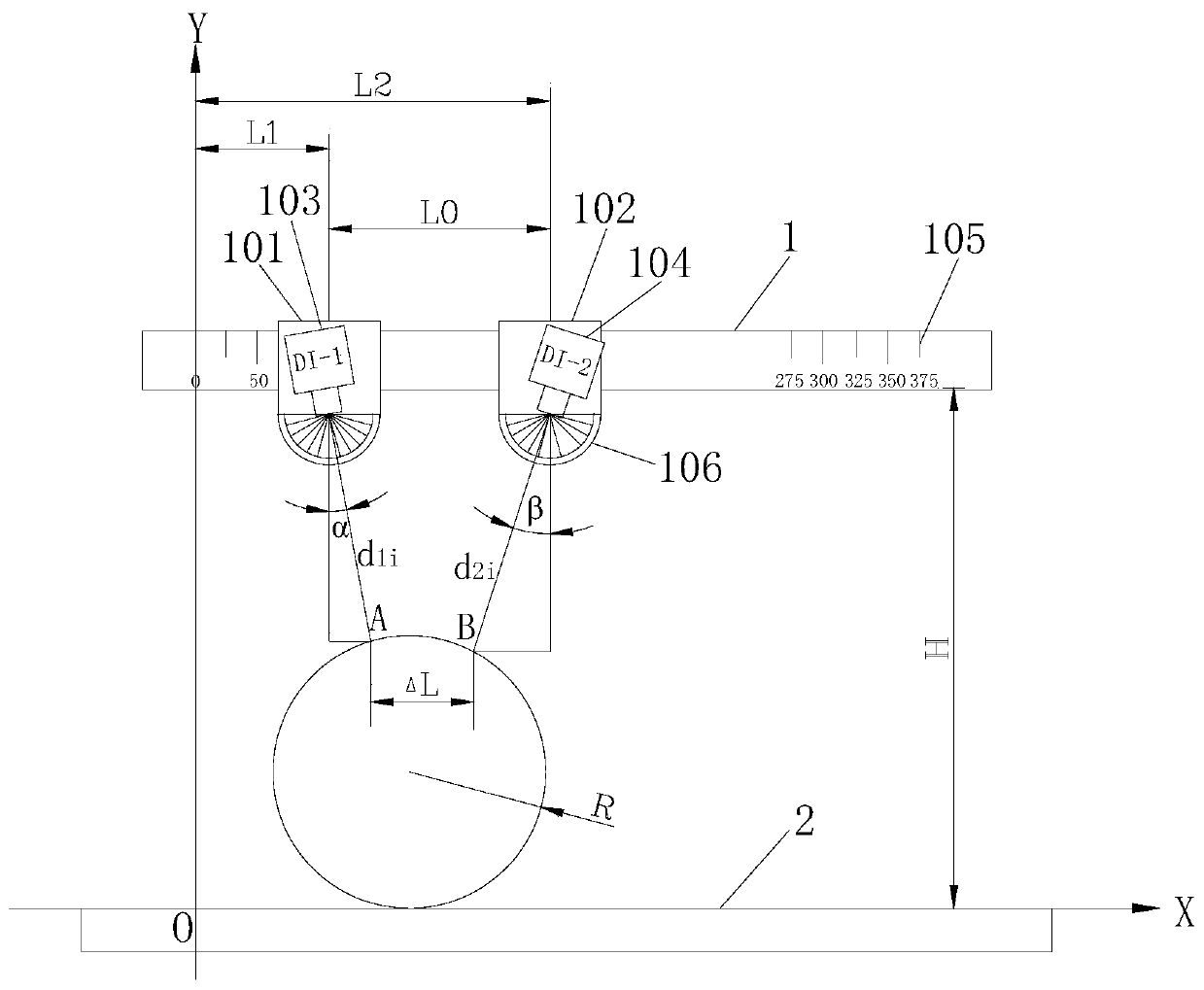

[0103] In Embodiment 1, since the installation angle α of the first distance measuring device 103 and the installation angle β of the second distance measuring device 104 are both 0°, the laser light emitted by the first distance measuring device 103 and the second distance measuring device 104 The beams are parallel to each other, and the lateral separation distance between the two laser beams falling on the wheel of the trolley is ΔL, and the distance between the first distance measuring device 103 and the second distance measuring device 104 is L 0 , then ΔL is equal to L 0 , that is, at L 0 When constant, ΔL is a constant value. In this embodiment, by rotating the first distance measuring device 103 and the second distance measuring device 104, the installation angles of the two distance measuring devices can be changed, so that the two laser beams emitted are no longer parallel to each other, but There is a certain included angle, and at the same time, by moving the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com