Solar light condensation heat collecting system and method

A solar energy concentrating and solar energy technology, applied in the field of solar energy utilization, can solve the problems such as the inability of the dish-type heat collector to achieve vacuum insulation, the inability to realize small-scale distributed energy applications, and the large cosine loss of the trough-type heat collector, and to avoid the Inability to collect heat in vacuum, avoid small-scale application of towers, and improve the effect of mirror field utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

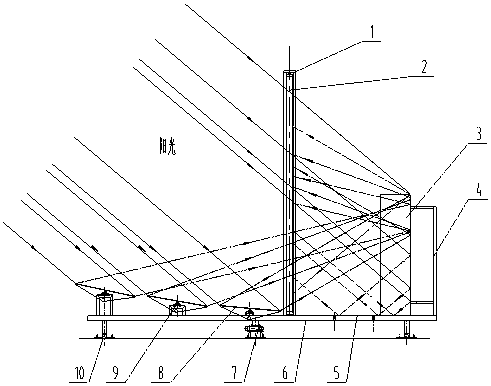

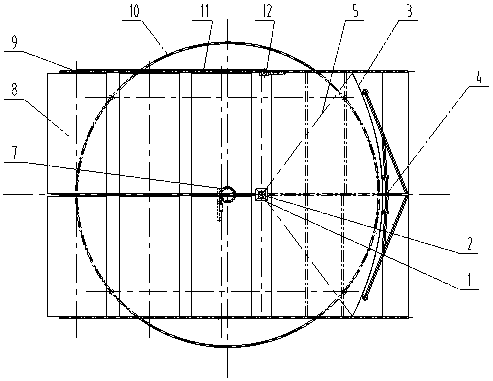

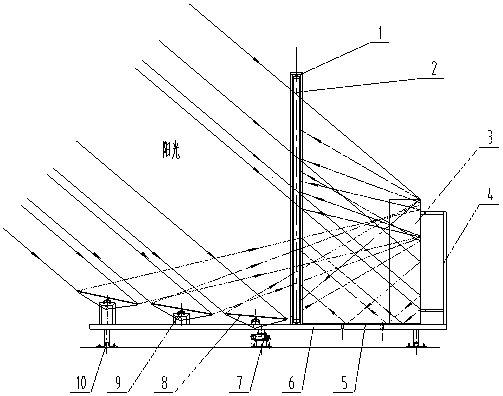

[0028] A solar energy concentrating heat collection system at least includes a heat collector 1, a vertical reflector group 3, a chassis 6, a chassis drive mechanism 7, a Fresnel reflector group 8, a bearing seat 9, a circular guide rail 10, and a rotating connecting rod 11 , connecting rod drive mechanism 12 and solar control unit;

[0029] The vertical reflector group 3 is a reflector around the heat collector 1, arranged towards the sun, the axis of the vertical reflector group 3 is parallel to the central axis of the heat collector 1, and the vertical reflector group 3 is used to reflect the incident light of the sun to the heat-absorbing surface of the collector 1;

[0030] The Fresnel reflector group 8 is on the other side of the heat collector 1, and is used to condense and reflect the sunlight on the other side of the heat collector 1 to the heat-absorbing surface of the heat collector 1; the Fresnel reflector group 8 The highest point will not affect the heat-absorbi...

Embodiment 2

[0034] Such as Figure 1A and Figure 1B As shown, a solar energy concentrating heat collection system is characterized in that it includes at least a heat collector 1, a heat collector bracket 2, an upright mirror group 3, an upright mirror group bracket 4, a bottom plane mirror group 5, and a chassis 6. Chassis driving mechanism 7, Fresnel mirror group 8, bearing housing 9, circular guide rail 10, rotating connecting rod 11, connecting rod driving mechanism 12 and solar control unit; the plane mirror used in erecting mirror group 3, The size of the upright mirror group 3 can be selected to be 12 meters high and 0.5 meter wide. The bracket 4 of the erected reflector group is fixed, the horizontal tangent of the erected reflector group 3 is an approximate parabola, the equation of the parabola is y²=2px, the focal length is set to 25 meters, and the opening of the parabola is 100 meters; one heat collector is a 4-meter-long vacuum heat collector The height is 24 meters in ser...

Embodiment 3

[0037] Such as Figure 2A and Figure 2B As shown, a solar energy concentrating heat collection system at least includes a heat collector 1, a heat collector support 2, an upright reflector group 3, an upright reflector group support 4, a bottom plane reflector group 5, a chassis 6, and a chassis drive Mechanism 7, Fresnel mirror group 8, bearing housing 9, circular guide rail 10, rotating connecting rod 11, connecting rod driving mechanism 12 and solar control unit; erecting mirror group 3 adopts a height of 3 meters (multi-block splicing height) A flat mirror with a width of 1 meter and a thickness of 1mm is cold-formed, and a thick aluminum liner is attached to the back. The thickness of the thick aluminum liner is between 1mm-1.5mm. Then the composition is arranged, the horizontal tangent line of the vertical reflector group 3 is a parabola, and the mirror surface is arranged on the chassis 6 facing the sun, the vertical reflector group 3 is fixed with the vertical reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com