System for collecting thermal energy of hot dry rock with U-shaped well and use method thereof

A technology of hot dry rock and underground heat exchange system, which is applied in the field of thermal energy development of dry hot rock, can solve problems such as unclear exploration, and achieve the effects of increasing heat conduction effect, reducing overall cost, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

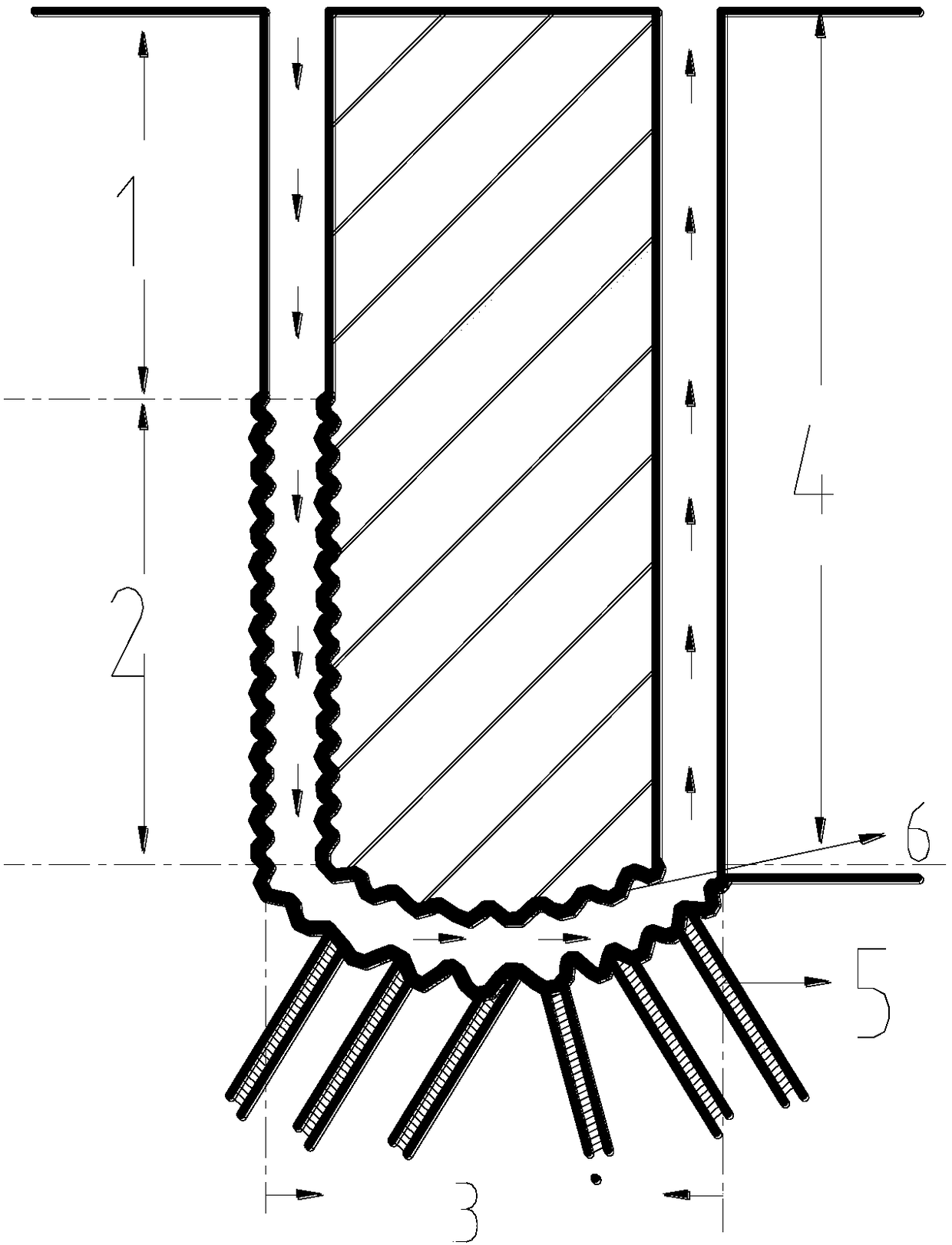

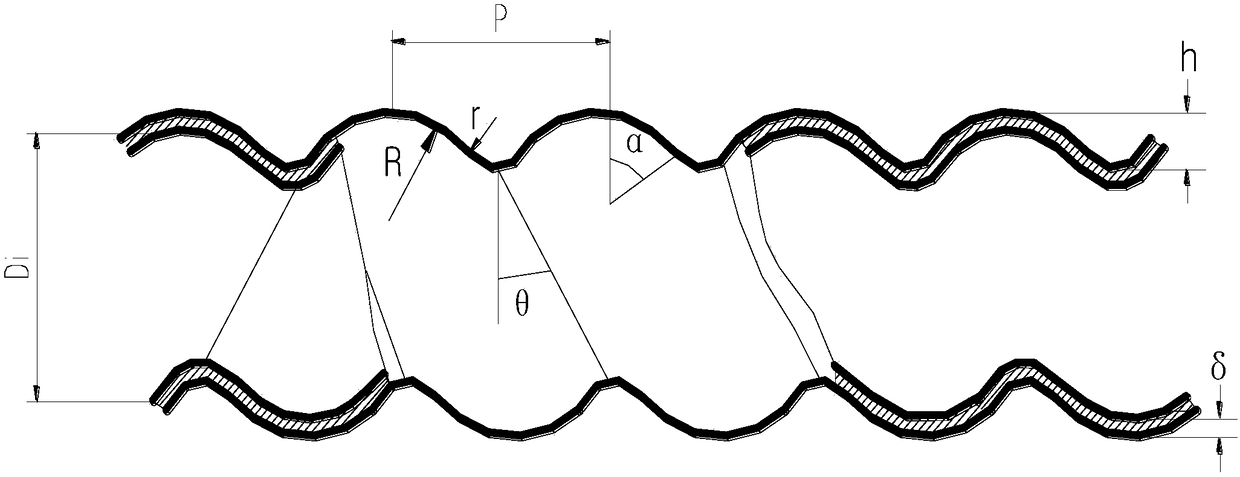

[0031] A system for collecting thermal energy of dry hot rock through a U-shaped well. The system for collecting thermal energy of dry hot rock is in the form of a "U"-shaped passage as a whole, including an injection casing and its insulation system 1, a cascaded heating system for rock heat utilization 2, and a long conductor Cheng swirling self-flushing underground heat exchange system 3, collection well casing and its insulation system 4, rock heat utilization cascade heating system 2 and injection casing and its insulation system 1 are connected together to form a "U"-shaped left vertical In the straight part, the rock heat utilization cascade heating system 2 and the injection casing and its insulation system 1 are located in the vertical shaft section of the connecting well, and the rock heat utilization cascade heating system 2 is set directly below the injection casing and its insulation system 1. The heat utilization cascade heating system 2 is connected with the inje...

Embodiment 2

[0039] In the thermal storage structure with low heat flow value and rock thermal conductivity, the system for collecting heat energy of dry rock through U-shaped wells is used. The system for collecting heat energy of dry rock is in the form of a "U"-shaped path as a whole, including injection casing and Its insulation system 1, rock heat utilization cascade heating system 2, long-lead swirl self-flushing underground heat exchange system 3, collection well casing and its insulation system 4, rock heat utilization cascade heating system 2 consists of array swirls It is formed by connecting self-flushing underground heat exchangers to form a rock heat utilization cascade heating system 2, which requires 25 sets of swirling self-flushing underground heat exchangers. The long-lead swirling self-flushing underground heat exchange system 3 is composed of groups of swirling self-flushing underground heat exchangers connected to form a long-lead swirling self-flushing underground heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com