Ultrasonic vibrating vacuum preloading test system

A test system, ultrasonic technology, applied in soil material testing, material inspection products, infrastructure engineering, etc., can solve problems such as drainage plate silting, achieve the effect of small soil disturbance, stable and uniform power output, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

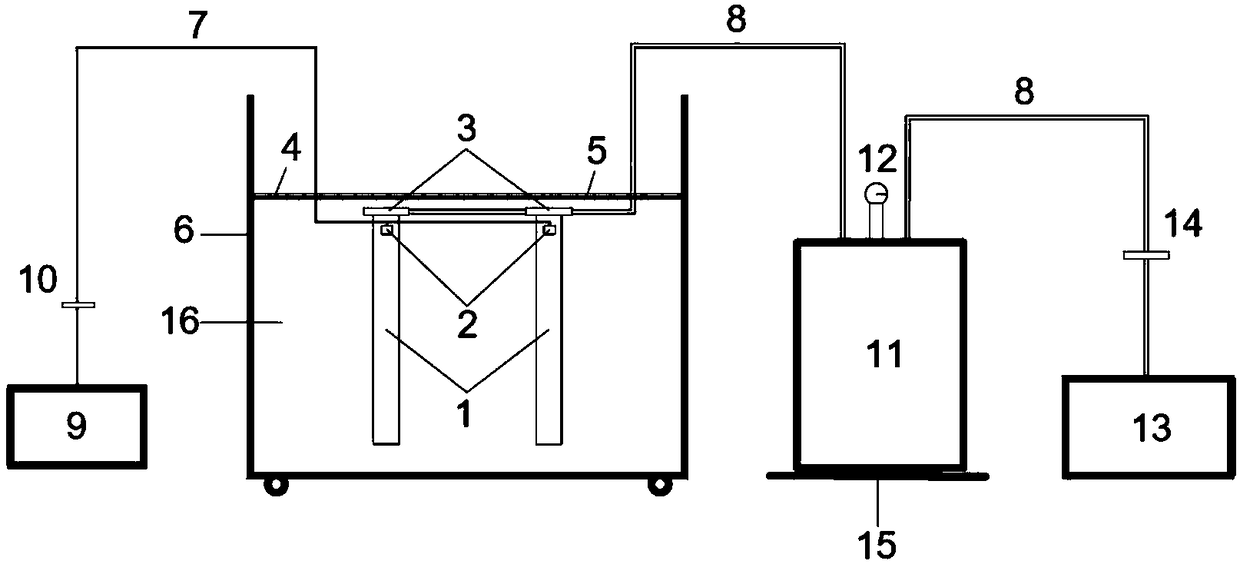

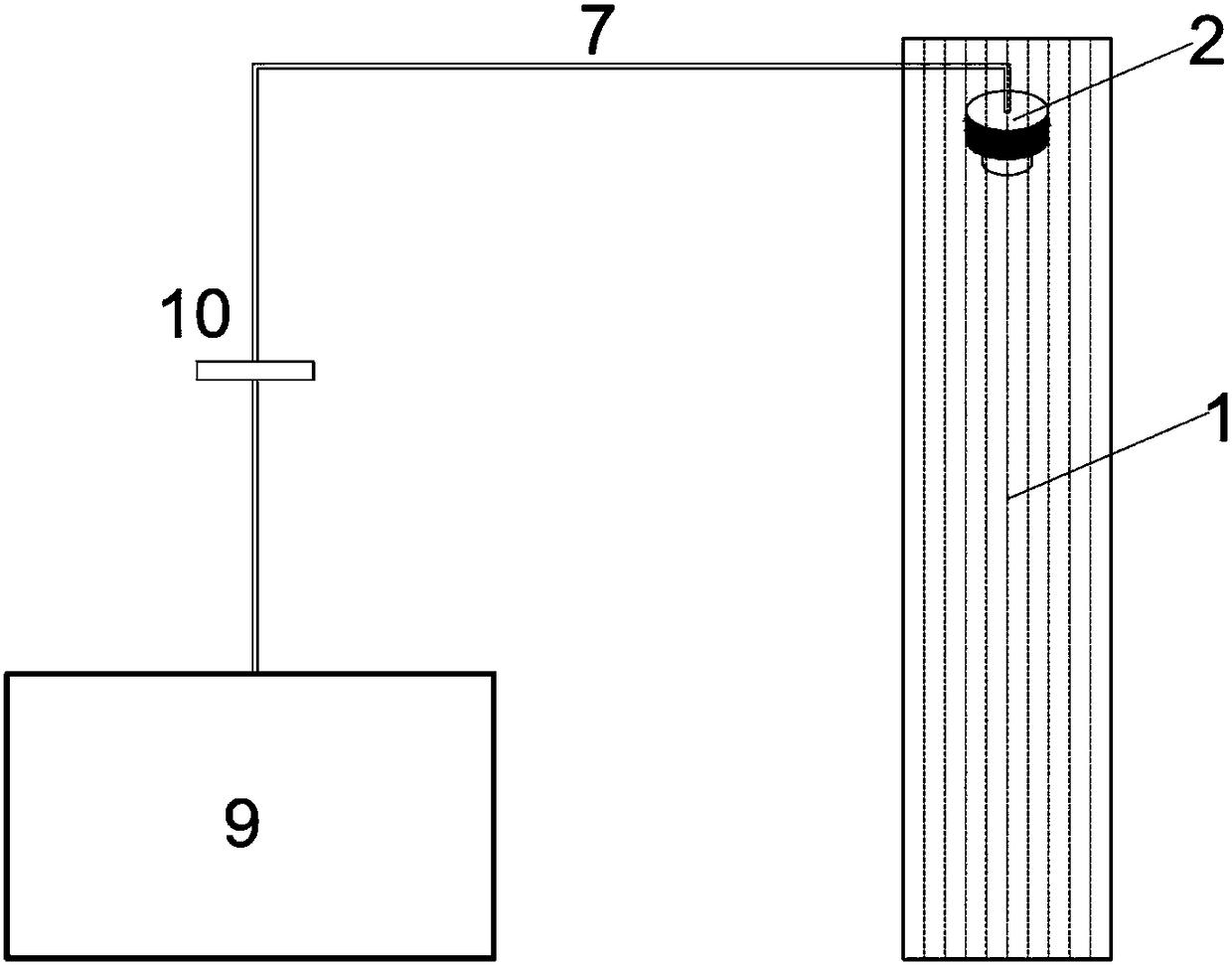

[0017] see figure 1 and figure 2 , the present invention provides a kind of ultrasonic vibration vacuum preloading test system, and concrete test device connection comprises, adds test soil sample 16 in the plexiglass model box 6, inserts ultrasonic vibration drainage plate (drainage plate 1 and ultrasonic transducer One end of the ultrasonic vibration drainage plate is connected to the ultrasonic generator 9 with a switch 10 through the data signal line 7, and the other end is connected to the drainage plate-steel hose conversion joint 3 connected to the steel wire hose 8; Lay one deck non-woven geotextile 4 earlier on the test soil sample, and lay one deck sealing film 5 above non-woven geotextile 4; The water-gas separation tank is placed above the electronic scale 15, and is connected with a vacuum pump 13 with a control valve 14.

[0018] The experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com