Device and method for directly measuring interfacial contact resistivity

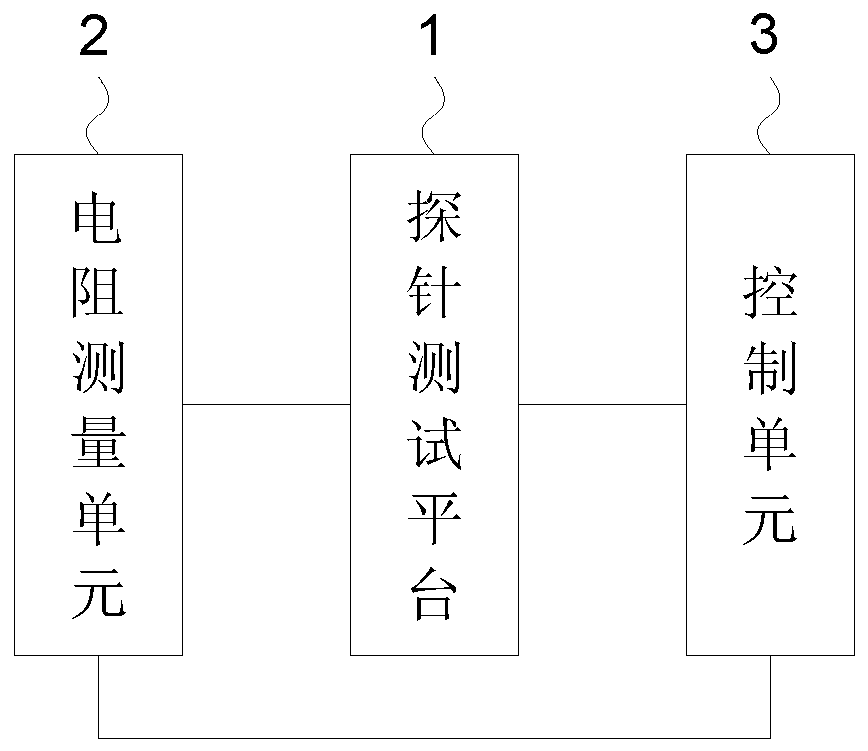

A technology of contact resistivity and interface, applied in measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., it can solve the problems of diffusion and inability to reflect well, and achieve simple operation and machine vision positioning. , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

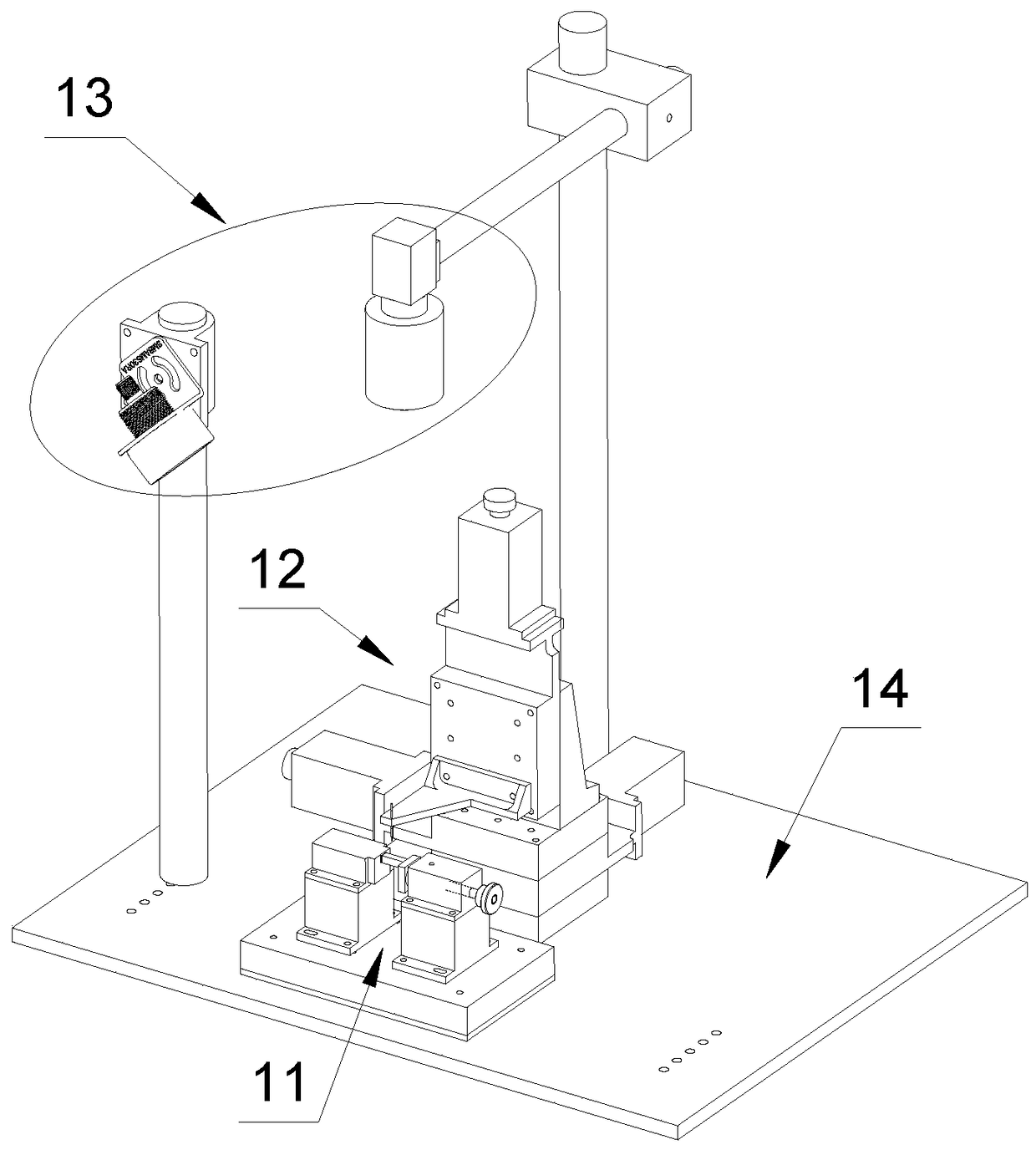

[0094] A device for directly measuring interfacial contact resistivity of the present invention measures a P-type CoSb below in conjunction with the examples and accompanying drawings 3Interfacial contact resistivity of basal cobalt ore thermoelectric elements.

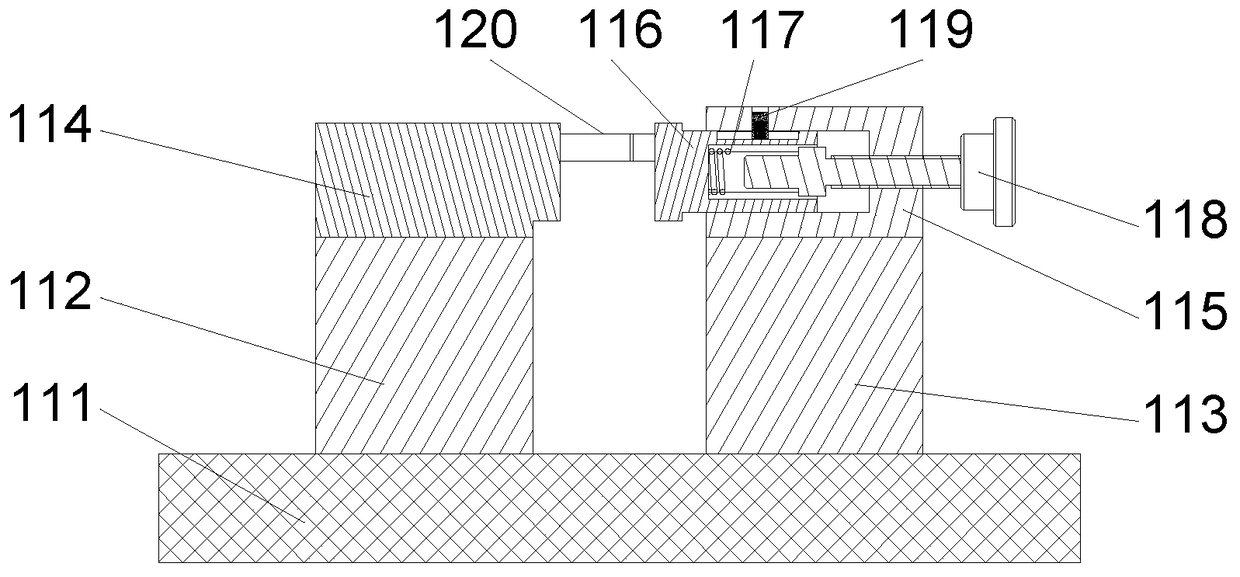

[0095] Step 1: Preparation including thermoelectric material CeFe 3.85 mn 0.15 Sb 12 , Barrier layer Ti 88 al 12 , and electrode Ni CeFe 3.85 mn 0.15 Sb 12 / Ti 88 al 12 / Ni block with a thickness of 8mm, cut to obtain a cross-sectional area of 3×3mm 2 The thermoelectric element, the two ends and the upper surface are ground flat, and the actual cross-sectional dimensions measured by a caliper are 3.02mm and 2.98mm. Use tweezers to install the thermoelectric element on the sample test fixture, which is located between the first electrode and the second electrode. , so that the surface to be tested is placed horizontally, and then the thermoelectric element is clamped.

[0096] Step 2: Collect the surface i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap