A Dynamic Parameter Tuning Method of Superheater Mechanism Model Combined with Field Data

A technology of dynamic parameters and on-site data, applied in special data processing applications, computer-aided design, geometric CAD, etc., can solve problems such as low efficiency, reduced credibility of simulation results, and time-consuming, and achieve the effect of improving simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

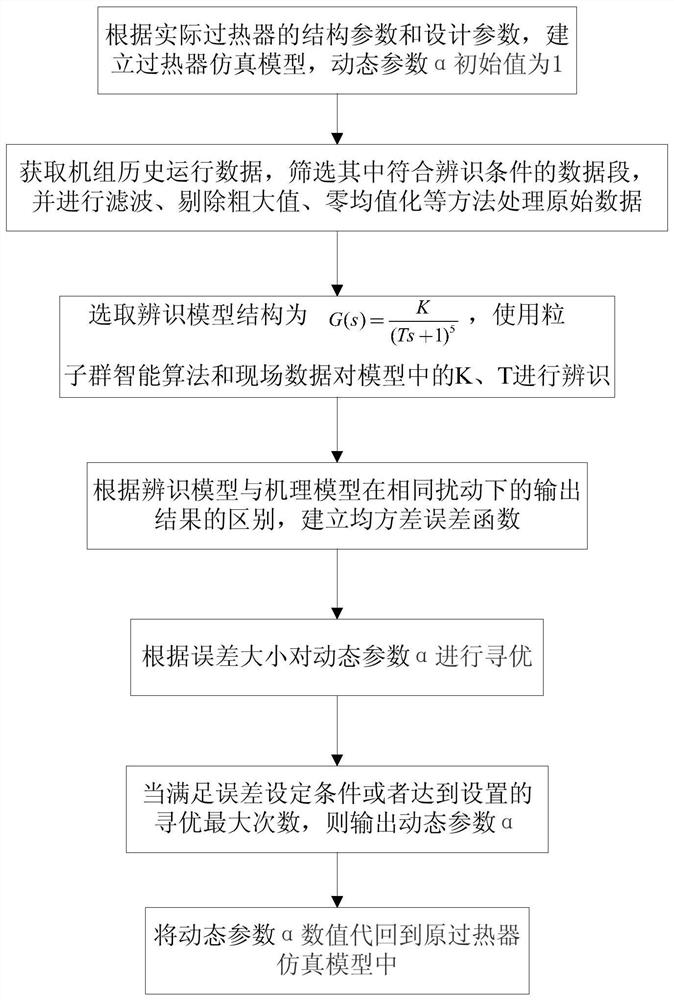

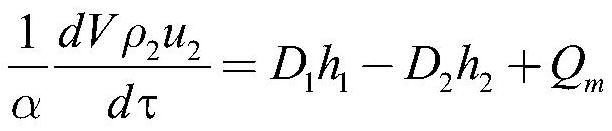

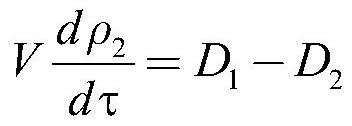

[0036] The present invention is a superheater mechanism model dynamic parameter setting method combined with on-site data. According to the working mechanism process of the superheater, some simplified assumptions are made for the superheater modeling, and the outlet parameters are used as the lumped parameters to establish the superheater mathematical model. Models, including mass conservation equations, energy conservation equations, heat transfer equations, heat storage equations, momentum conservation equations and differential equations, and the superheater is divided into five sections for modeling, and each section uses the same mathematical model. Based on the mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com