Overheat fault monitoring device and method for valve side sleeve of converter transformer

A converter transformer and fault monitoring technology, applied in transformer/inductor components, electrical component structure associations, electrical components, etc., can solve problems such as missed judgments, and achieve the effect of improving reliability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

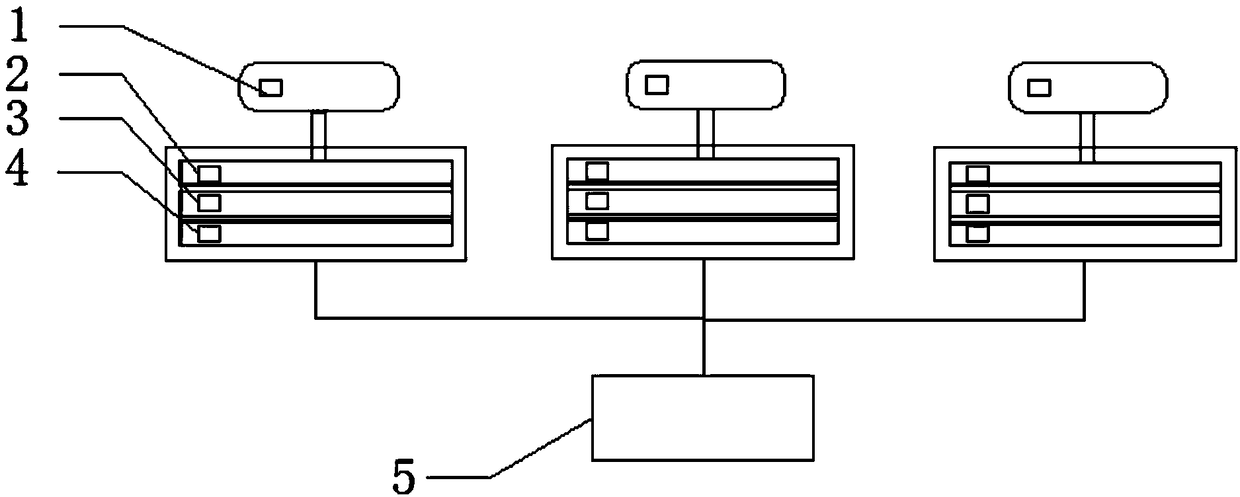

[0028] Such as figure 1 As shown, a converter transformer valve side bushing overheat fault monitoring device, including SO 2 Detecting head 1, processing module 2, battery 3, GSM module 4 and mobile terminal 5, described battery 3 is used for SO 2 Probing head 1 and processing module 2 are powered, the SO 2 The detection head 1 is directly installed in the air chamber of the valve side casing through the flange opening on the valve side casing air chamber, and is used to detect whether there is SO in the gas chamber. 2 gas, the SO 2 The working temperature range of the probe head 1 is -40°C to 120°C, the measurement range is 0ppm to 500ppm, and the measurement accuracy is 1ppm. The processing module 2 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com