Motor and stator iron core thereof

A stator iron core and iron core technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as high cost and achieve the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

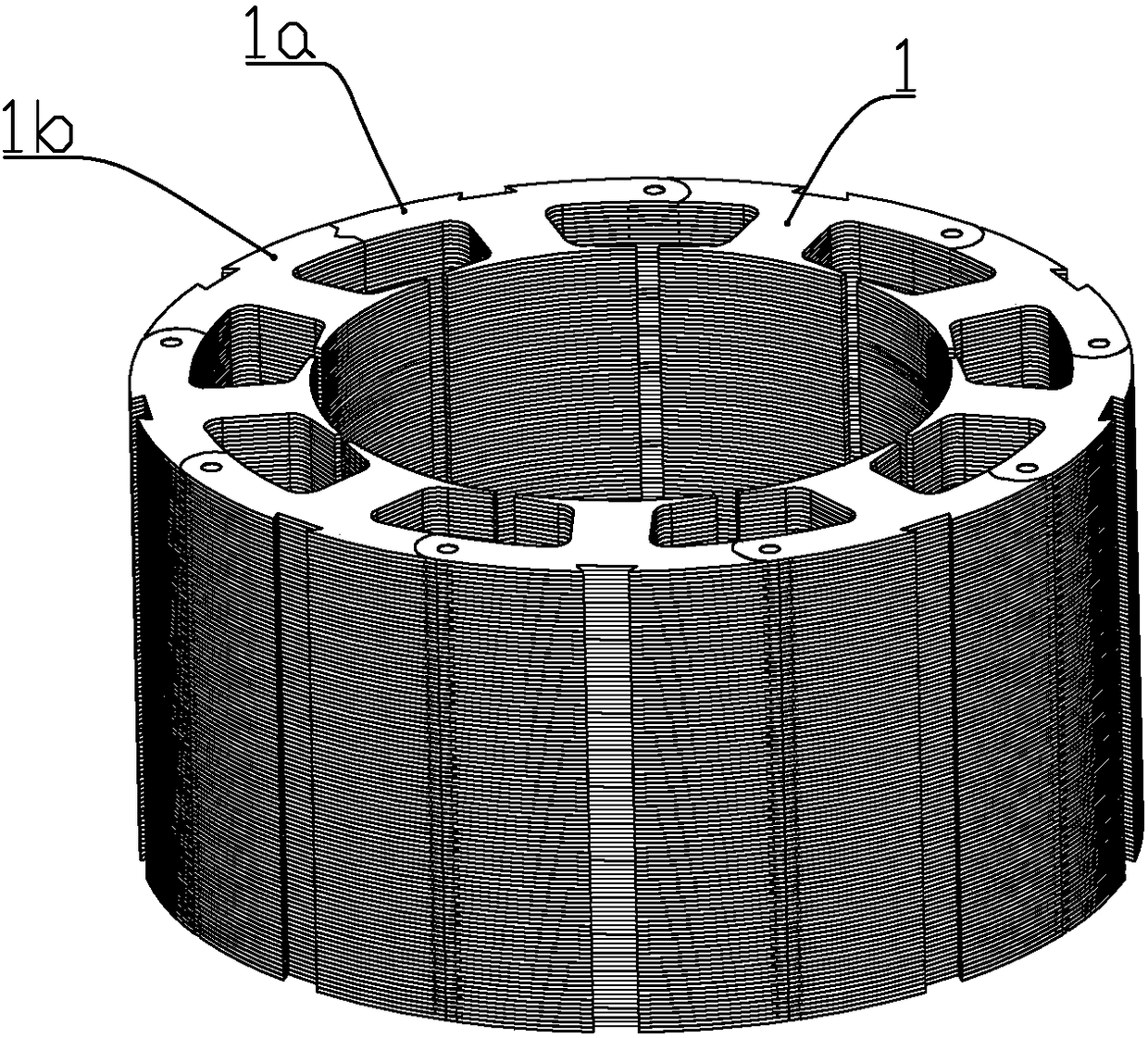

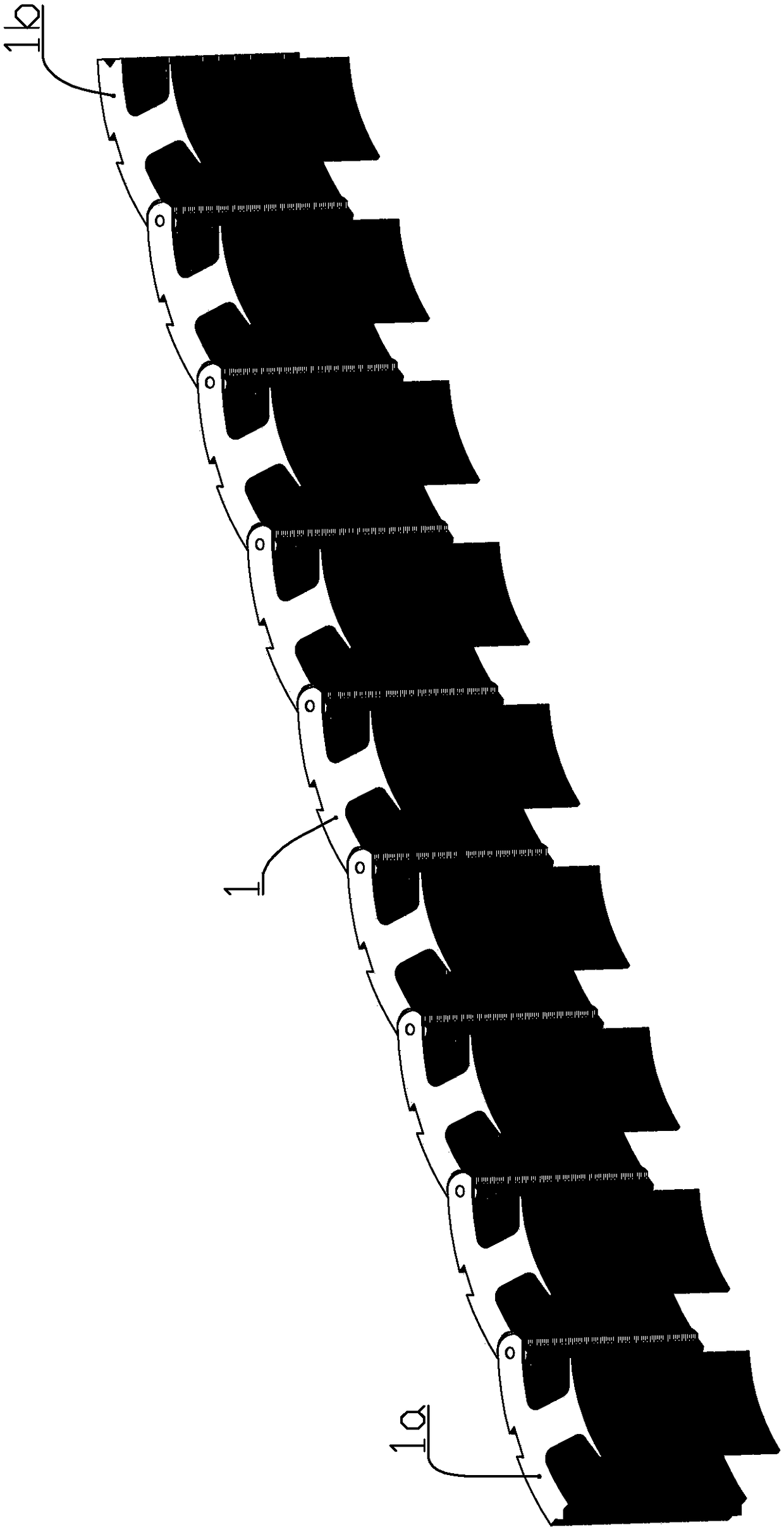

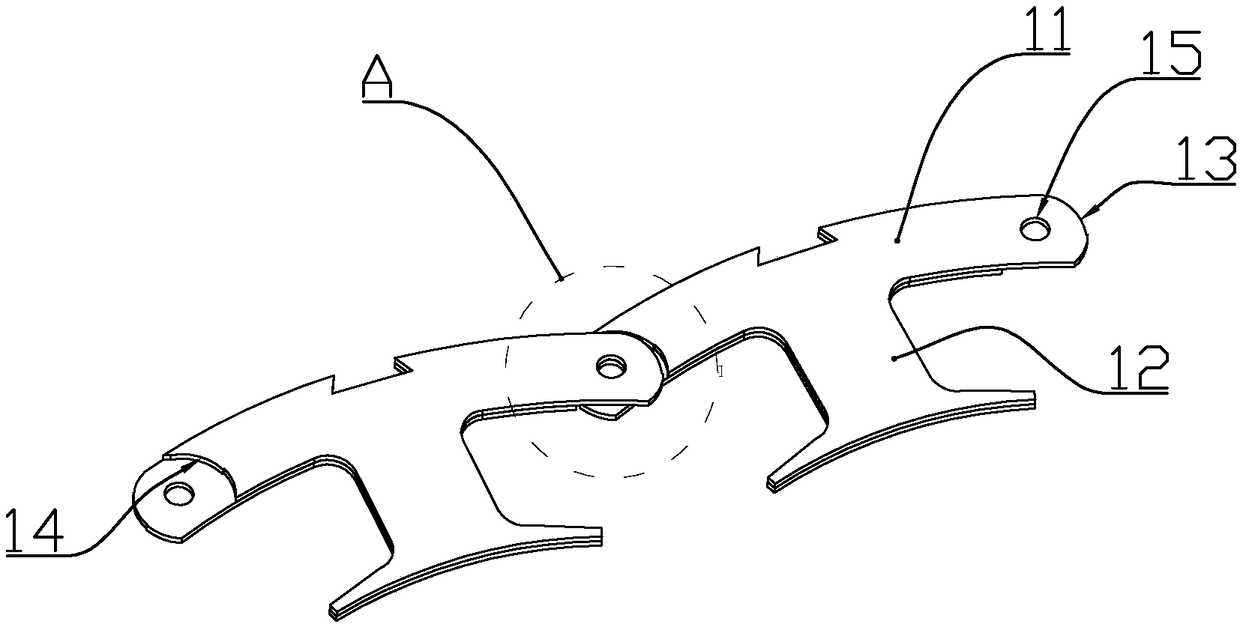

[0033] combine Figure 1 to Figure 6 As shown, this embodiment is a stator core of a motor, including a plurality of iron core layers spliced together along the axial direction of the motor, each iron core layer includes a plurality of iron core units 1, and each iron core unit It includes a T-shaped yoke part 11 and a winding installation part 12 connected in the middle of the inner side of the yoke part, and the core units of each core layer can be formed into a ring shape by the yoke part.

[0034] One end of the yoke portion is a concave portion 14, and the other end is a convex portion 13, and the yoke portion is provided with a hinge portion on one side of the convex portion, and the concave portion and the convex portion of the core units of the adjacent two core layers Staggered arrangement; the hinge parts of left and right adjacent iron core units located on different iron core layers are rotationally connected.

[0035] The hinge part shown in the figure is a circu...

Embodiment 2

[0045] combine Figure 7 to Figure 8 As shown, this embodiment is a stator core of a motor, which includes a plurality of core groups spliced together along the axial direction of the motor, and each core group includes 2-5 core groups spliced together along the axial direction of the motor Iron core layer, each iron core layer includes a plurality of iron core units, each iron core unit includes a yoke iron part and a winding installation part connected in the middle of the inner side of the yoke iron part, the iron core unit of each iron core layer can The ring shape is surrounded by the yoke portion.

[0046] One end of the yoke part is a concave part, and the other end is a convex part, and the yoke part is provided with a hinge part on one side of the convex part, and the concave parts and convex parts of the core units of two adjacent core layers are alternately arranged ; The hinges of the left and right adjacent iron core units located on different iron core group...

Embodiment 3

[0053] This embodiment is a motor, including a stator and a rotor. The stator includes the stator core of the foregoing embodiment, and a winding wound on the stator core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com