Automatic balling machine for slide rail

An automatic and bead-loading technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of consuming a lot of time and energy in research and development, difficulty in mechanical automatic assembly design, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

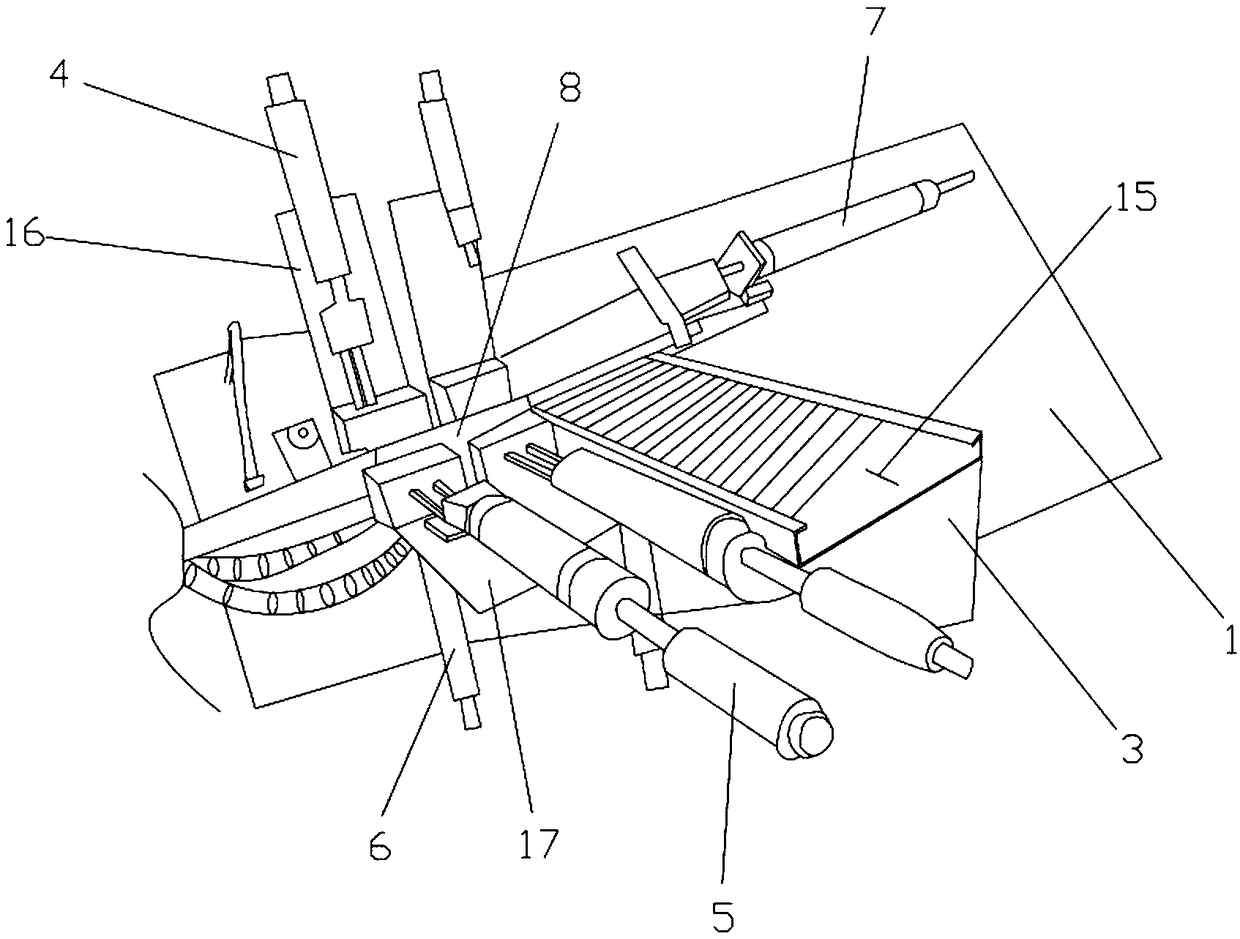

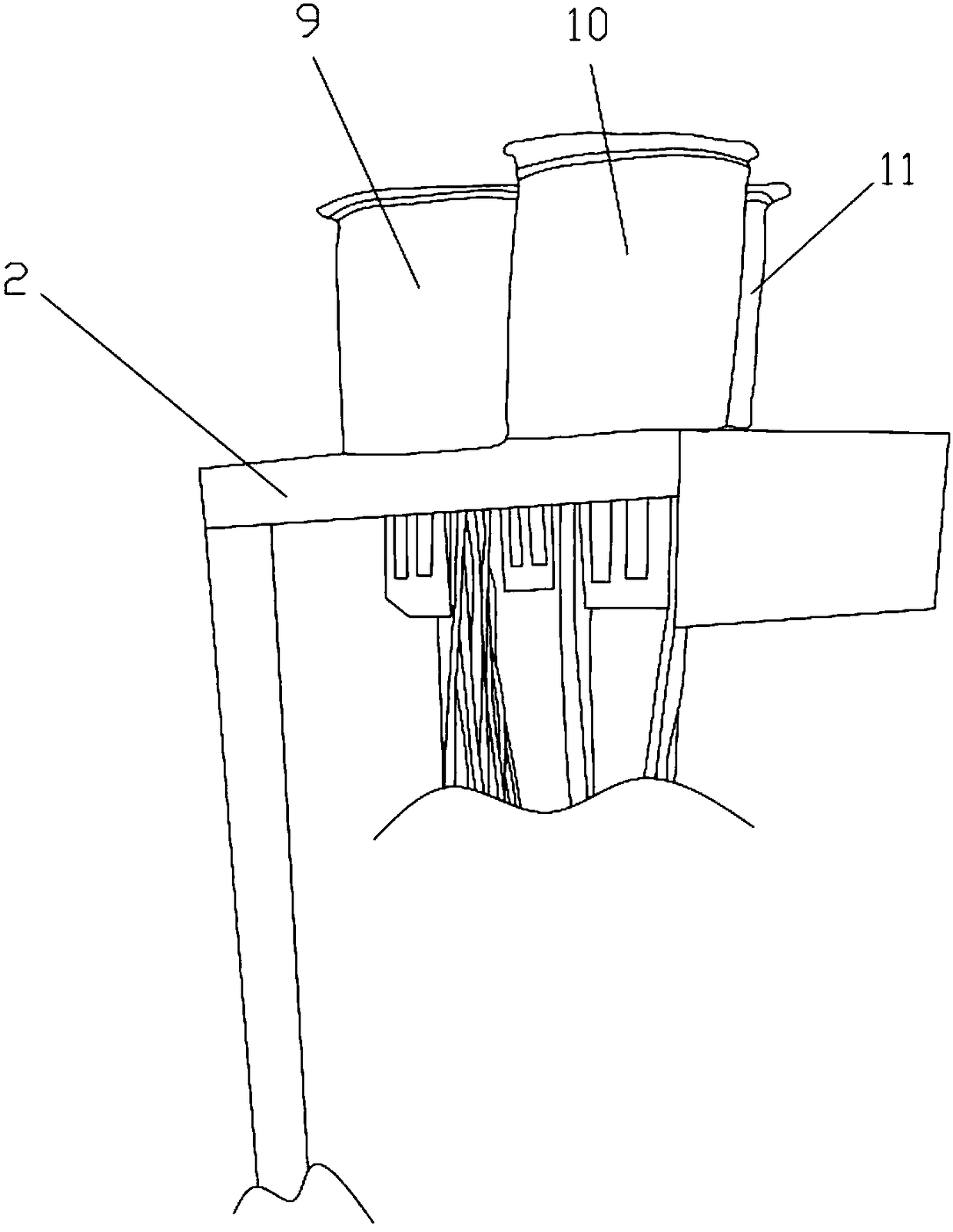

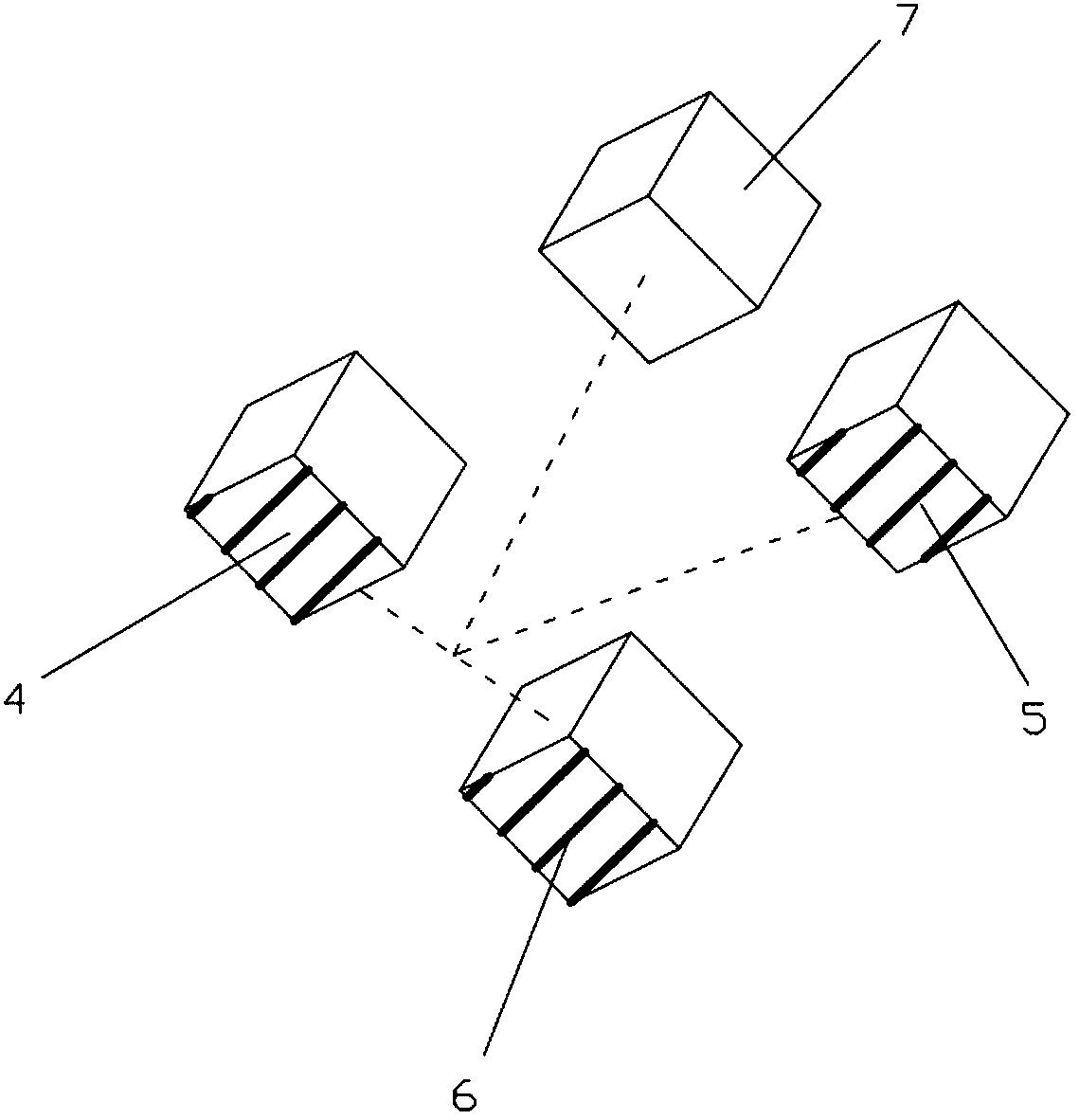

[0019] Such as Figure 1-Figure 4 As shown, a slide rail automatic bead loading machine includes a base frame 1, and the base frame 1 is provided with a supporting platform 2, a feeding platform 3, a first cylinder group 4, a second cylinder group 5, and a third cylinder group 6. The fourth cylinder group 7 and the mounting block 8, the support table 2 is provided with the first vibrating plate 9, the second vibrating plate 10 and the third vibrating plate 11, the first cylinder group 4, the second vibrating plate The piston rods of the cylinder group 5 and the third cylinder group 6 are fixedly connected with ejector rods, and the output direction between the first cylinder group 4 and the second cylinder group 5 and between the second cylinder group 5 and the third cylinder group 6 Perpendicular to each other, the piston rod of the fourth cylinder group 7 is provided with a push block, and the output direction of the fourth cylinder group 7 is respectively connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com