Vertical spiral degassing device for superfine powder packaging machine

A vertical spiral, degassing device technology, applied in packaging, transportation and packaging, packaging types and other directions, can solve the problems that affect the production efficiency of enterprises, do not have degassing devices, increase the volume of packaging bags, etc., and achieve easy and precise control. , The effect of improving the working environment and improving the quality of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

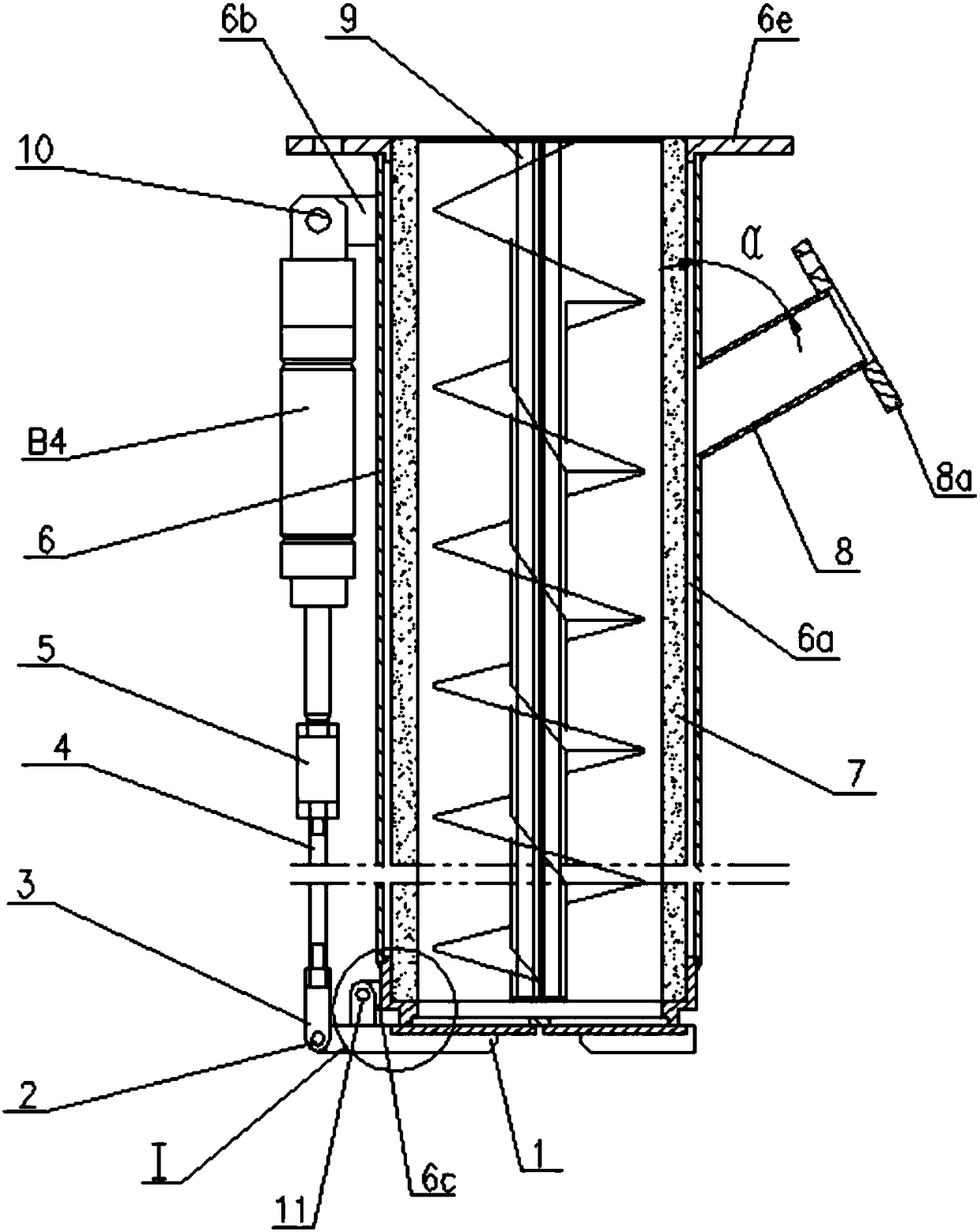

[0018] What needs to be explained here is that the orientation words left, right, up, down, top, and bottom are based on figure 2 The views shown are defined by reference, and it should be understood that the use of said localizers should not limit the scope of protection claimed in this application.

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

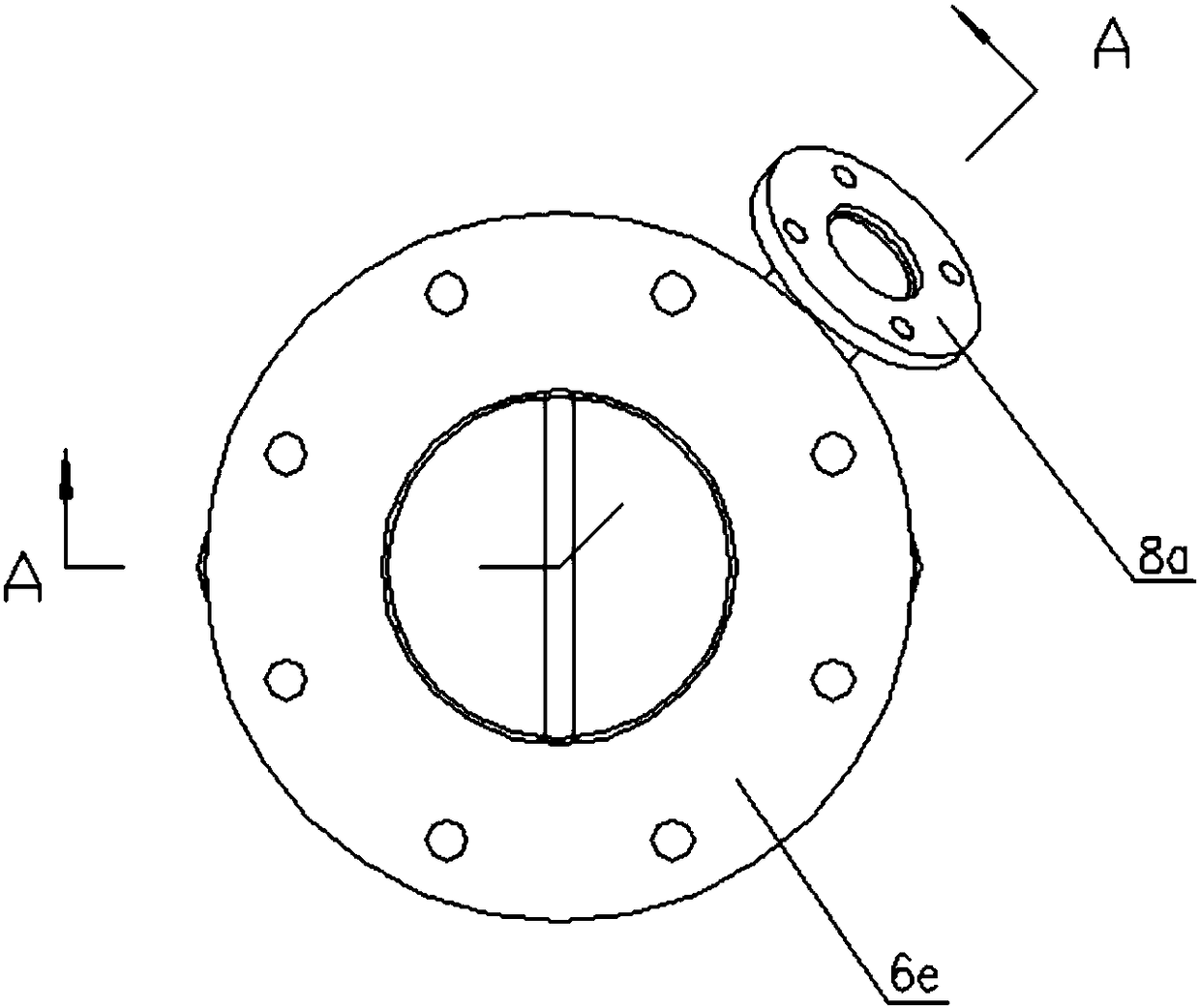

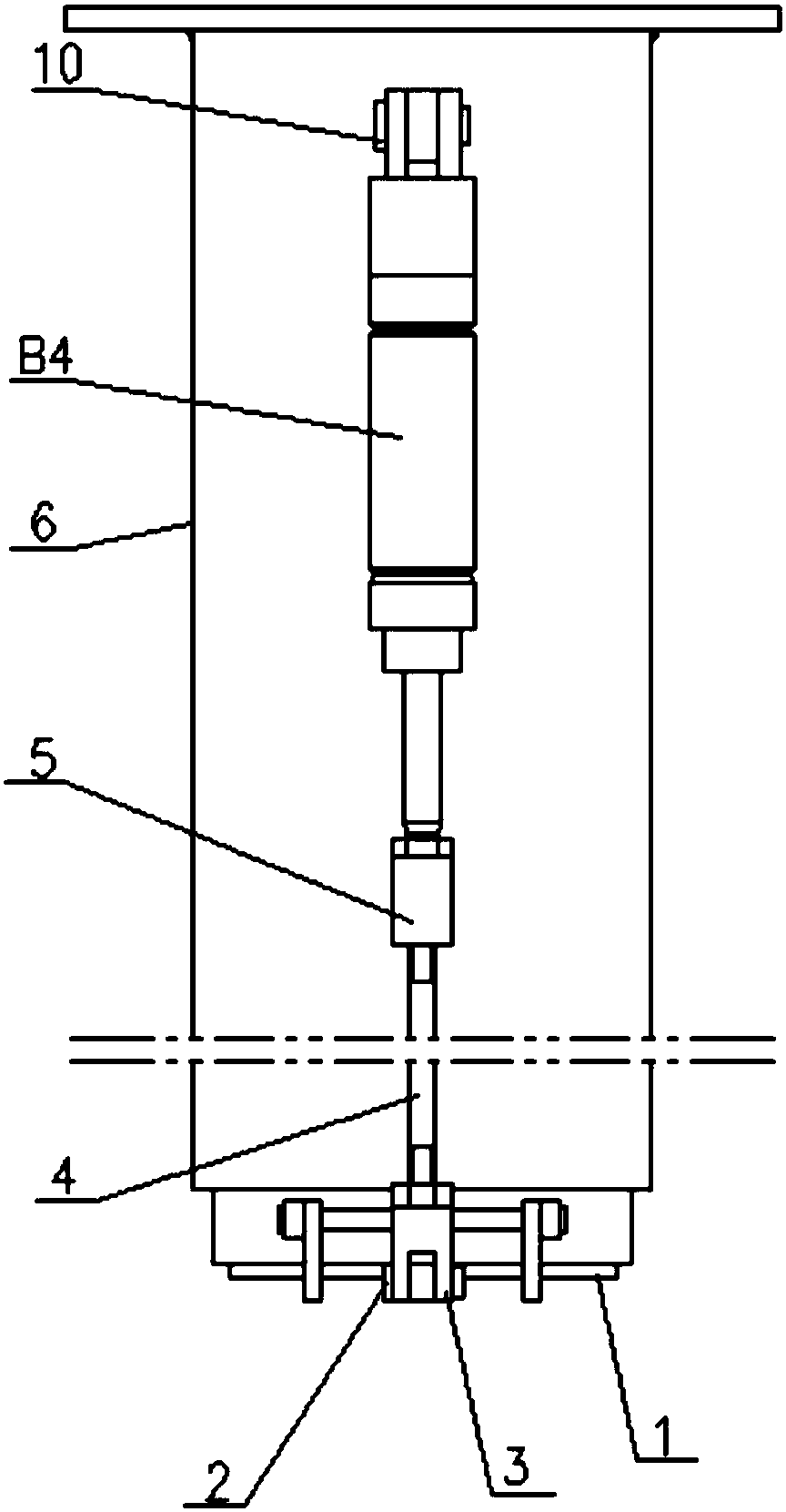

[0020] Such as Figure 1 to Figure 4 As shown, a vertical spiral degassing device for a superfine powder packaging machine, which includes a vertically arranged blanking sleeve 6, and a door control assembly is respectively arranged on the outer walls of the left and right sides of the blanking sleeve 6, and the blanking sleeve 6 The interior of the microporous tube 7 is equipped with a microporous tube 7 which allows air to pass through to filter out fine powder particles. There is a cavity 6a between the microporous tube 7 and the inner wall of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com