A kind of spandex waste liquid recycling method

A waste liquid and spandex technology, applied in textiles and papermaking, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve problems such as inability to maximize waste liquid reuse, and achieve significant economic and social benefits Obvious effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

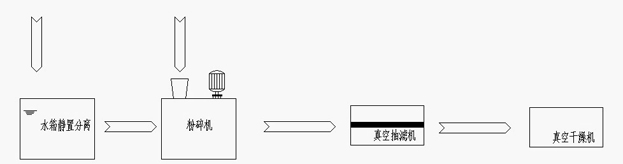

Method used

Image

Examples

Embodiment 1

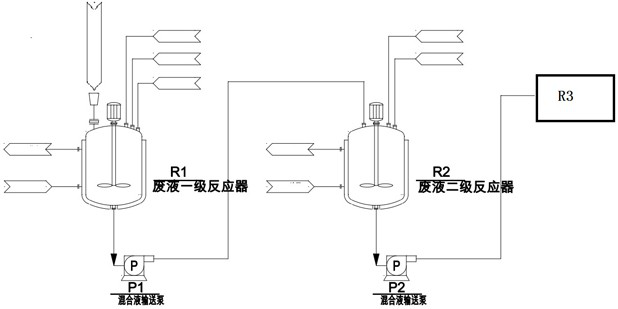

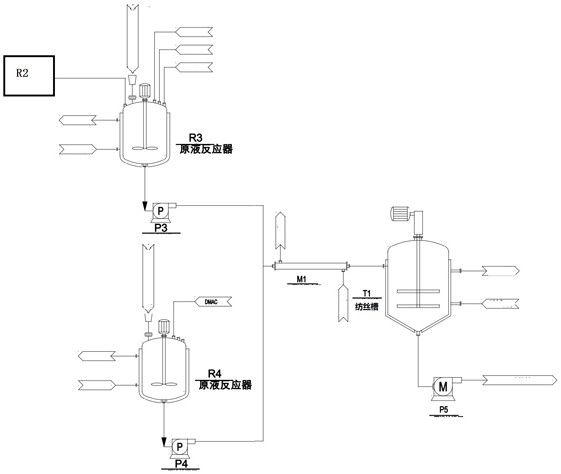

[0029] (1) The first waste liquid solid pulverized matter is put into the waste liquid primary reactor R1, and 90 degrees hot water is introduced into the jacket of the reactor to heat, and the solid is melted and stirred. According to the analysis result of the NCO value of the material, in the reaction Add metered 4,4'-diphenylmethane diisocyanate MDI and polytetrahydrofuran PTMG to the kettle, and continue to stir and react for 30-120 minutes. After the NCO value reaches the requirement of about 2.35, the gear pump is used to send the waste liquid to the secondary reaction. Device R2;

[0030] (2) Add the DMAC solution to the waste liquid secondary reactor R2 according to the metering, so that the solid content is 27%, and stir and mix the pre-polymer sent from the waste liquid primary reactor R1, and then add the prepared polymer after mixing fully. Mixed amine solution, the mixed solution of EDA, DEA, PDA three amines and DMAC, the proportion of amine is 7%, the polymeriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dynamic viscosity | aaaaa | aaaaa |

| dynamic viscosity | aaaaa | aaaaa |

| dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com